Processing methods for producing fastening devices

The technology of a fastening device and processing method is applied in the direction of friction clamping detachable fasteners, connecting components, mechanical equipment, etc., which can solve the problems of uneven distribution of electric field intensity, high manufacturing cost, and large space occupation, and achieve The surface electric field intensity distribution is uniform and stable, the production cost is low, and the appearance is beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

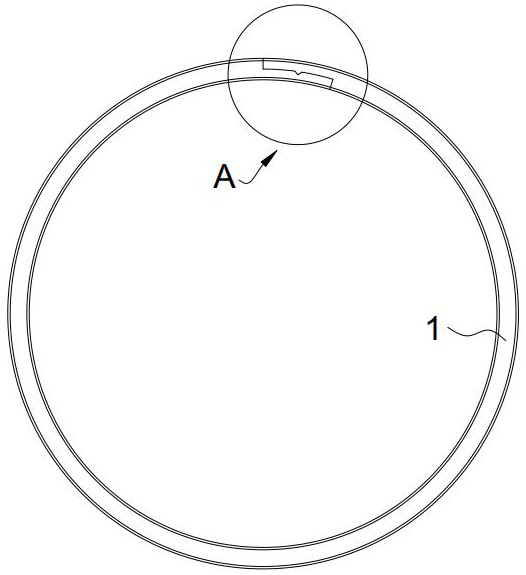

[0050] Such as Figure 3 to Figure 7 As shown, the embodiment of the present invention provides a fastening device, the fastening device is used on the high-voltage transformer magnetic core, suppresses or prevents the magnetic core from generating parasitic capacitive coupling during the operation of the transformer, isolates static electricity or electric field interference, and avoids Products that are affected by adverse factors due to breakdown between high-voltage electrical components.

[0051] Such as image 3 As shown, the fastening device includes a body 1 in a ring structure, and the body 1 has an opening. The body 1 in this embodiment is a ring structure, obviously the body 1 can also be a square ring structure, a hexagonal ring structure or other polygonal ring structures.

[0052] The main body 1 is provided with a first matching part 11 on one end of the opening, and a second matching part 12 on the other end of the opening; the first matching part 11 and the ...

Embodiment 2

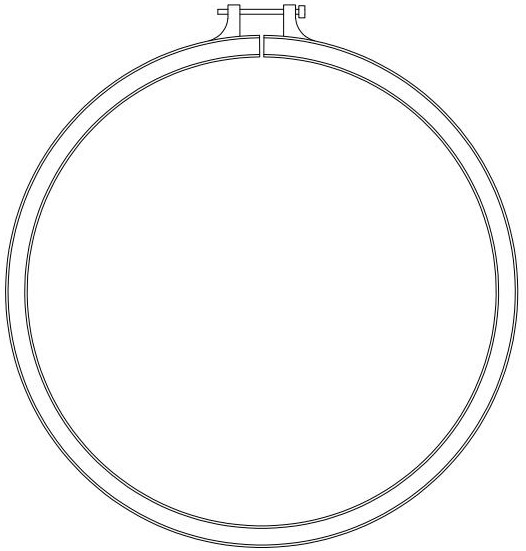

[0062] Such as Figure 8 with Figure 9 As shown, the embodiment of the present invention provides a fastening device, which is basically the same in structure and principle as the fastening device described in the first embodiment. Each includes a body 1 with an opening and a ring structure, a first matching portion 11' disposed on one end of the opening of the body 1 and a second matching portion 12' disposed on the other end of the opening of the body 1, and connecting the first The connecting piece 2 of the matching part 11' and the second matching part 12'.

[0063] The difference is that if Figure 9 As shown, the first fitting part 11' and the second fitting part 12' in this embodiment are left and right butt-fitted to form a joint part. Another example Figure 8 As shown, the countersunk screw of the connector 2 is inserted into the joint portion from the axial direction of the body 1 to connect and fix the first fitting portion 11 ′ and the second fitting portion ...

Embodiment 3

[0066] Such as Figure 10 As shown, the embodiment of the present invention provides a processing method for producing a fastening device, and the processing method is used to produce a fastening device for a high-voltage transformer magnetic core; the fastening device for a high-voltage transformer magnetic core can be the first embodiment or the The magnetic core fastening device described in Example 2.

[0067] The processing method for producing the fastening device provided in this embodiment includes the following steps:

[0068] Step S100 , cutting: measure and calculate the unfolded size of the entire ring of the fastening device according to actual needs, and cut out the unfolding material required for making the fastening device by using metal plates.

[0069] The measurement and calculation of the unfolded size of the entire ring of the fastening device is based on the measurement and calculation of the outer circumference of the transformer magnetic core to be fas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com