Electromechanical contact fuse for warhead of aerial rotary rocket projectile

A warhead and rocket technology, applied in the field of electromechanical trigger fuze of aviation rotary rocket warhead, can solve the problems of high cost, low action rate, high dud rate, etc., and achieve the effect of low cost, high action reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing of description, the present invention will be further described.

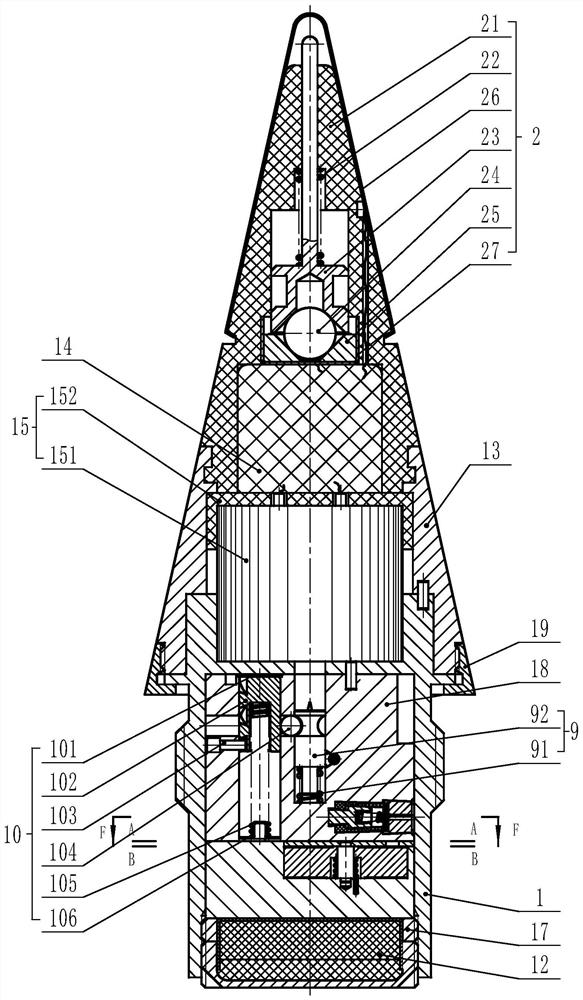

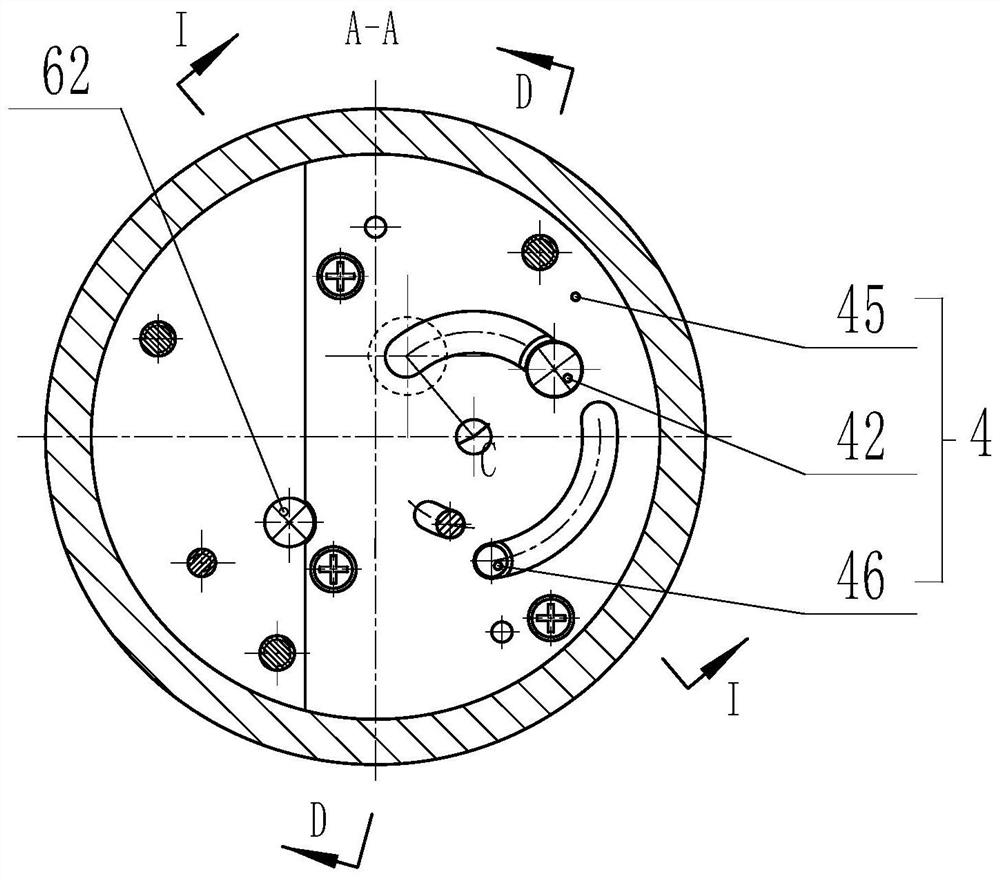

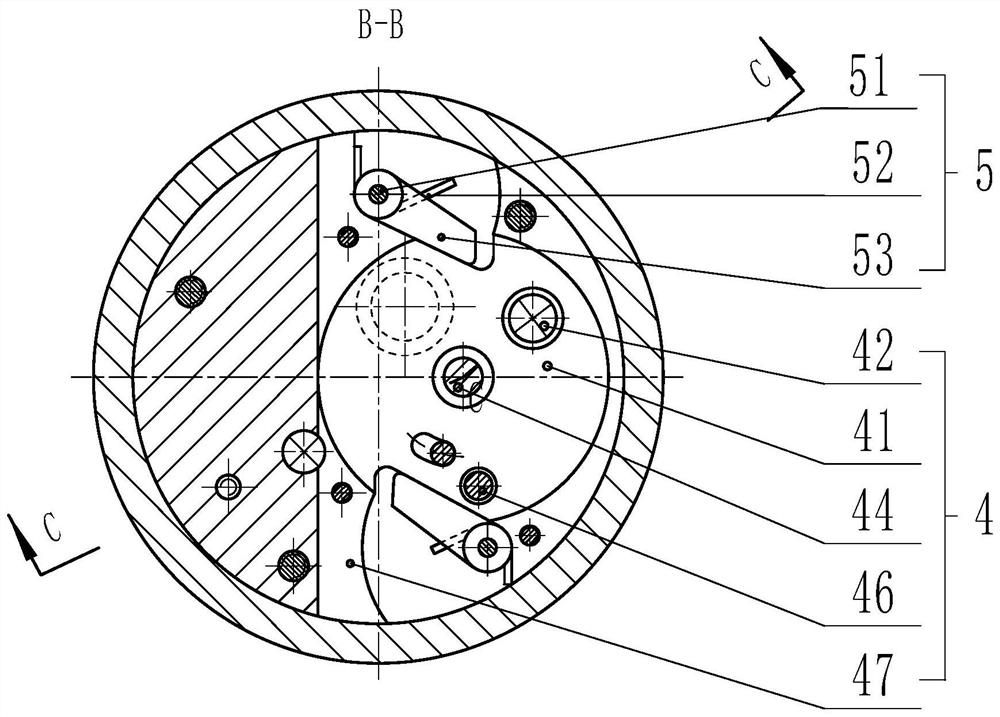

[0019] Such as Figure 1~Figure 10 As shown, an electromechanical trigger fuze of an aviation rotary rocket warhead includes a body 1, a bump trigger switch 2, an inertial trigger mechanism 3, an explosion-proof mechanism 4, a centrifugal safety mechanism 5, a safety plate safety mechanism 6, a failsafe mechanism 7, Thermal battery activation mechanism 9, recoil safety mechanism 10, detonator tube 11, detonator tube 12, upper body 13, circuit box 14, thermal battery assembly 15, electric ignition tube assembly 16, pressure ring 17, firing body 18, backup screw 19 and at least one short circuit switch 8. The bump trigger switch 2 is composed of a cone segment with a small upper part and a larger lower part and a cylindrical segment coaxially connected to the bottom end of the cone segment. Smooth connection. The circuit box 14 is arranged at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com