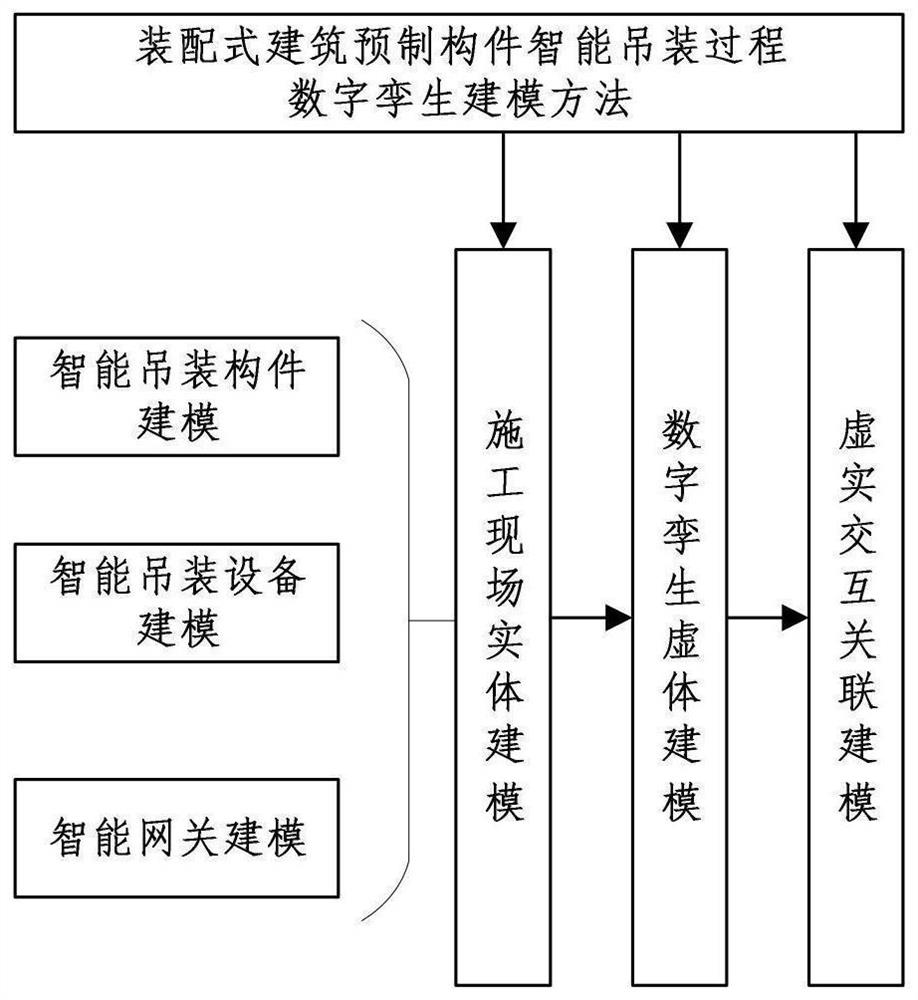

Digital twin modeling method for intelligent hoisting process of prefabricated parts of fabricated building

A technology of prefabricated components and modeling methods, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve problems such as difficult data mapping, not intuitive enough, and redundant information, so as to improve the level of informatization and construction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Take the hoisting process of a typical component on a prefabricated construction site—a laminated slab—as an example.

[0047] First, the smart hoisting laminated slab is modeled.

[0048] During the manufacturing process of laminated boards, intelligence ensures that the laminated boards meet the quality requirements. The active RFID tag and embedded terminal X are closely attached to the laminated board to form an intelligent hoisting laminated board. By scanning the RFID tag, the unique number of the laminated board and all characteristic information such as the manufacturer, production location, material, and size of the laminated board can be identified. The embedded terminal X adopts STEM32 and integrates real-time data collection and preprocessing APP, which can sense the position, stress and strain, wind speed and other information of the laminated board in real time, and store, calculate and transmit the data.

[0049] Second, smart crane modeling.

[0050]A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com