Farmland straw crushing and rotary tillage all-in-one machine

A technology of straw crushing and integrated machine, which is applied to agricultural machinery and tools, agriculture, shovels, etc. It can solve the problems of complicated operation, time-consuming and laborious, and slow down the efficiency of straw processing, so as to achieve convenient use, improve soil turning efficiency, and improve resource utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

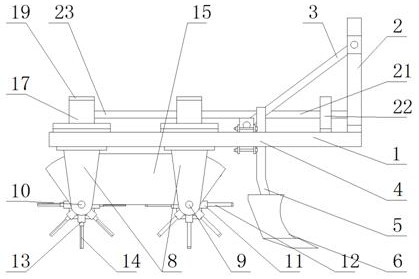

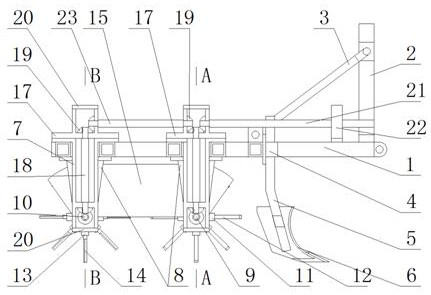

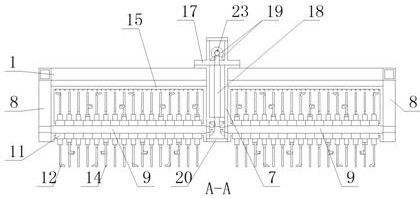

[0022] see Figure 1-4 , the present invention provides a technical solution: an all-in-one farmland straw crushing and rotary tillage machine, including a frame 1, and a support beam 2 is provided on the top surface of one end of the frame 1. Specifically, the support beam 2 is V-shaped, with an opening The two ends of the side are welded downwards with the frame 1. The front end of the frame 1 is provided with a guide shell 4, and the guide shell 4 is detachably connected with a vertical rod 5. Specifically, the top of the vertical rod 5 runs through the guide shell 4, and is connected with the guide shell 4. The shell 4 is connected by bolts, the bottom end of the vertical rod 5 is provided with a double-sided moldboard 6, the support beam 2 is pierced with an input shaft 21, and one end of the input shaft 21 is rotatably connected with a mounting seat 22 detachably connected with the frame 1 Specifically, the mounting seat 22 is matched with the end of the input shaft 21 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com