Multifunctional workbench for mold design

A mold design and workbench technology, which is applied to the legs of general furniture, the combination and application of two or more different types of furniture, etc., can solve the problems of inconvenient transfer and confusion of tools, and achieve easy rotation and later use. , the effect of rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

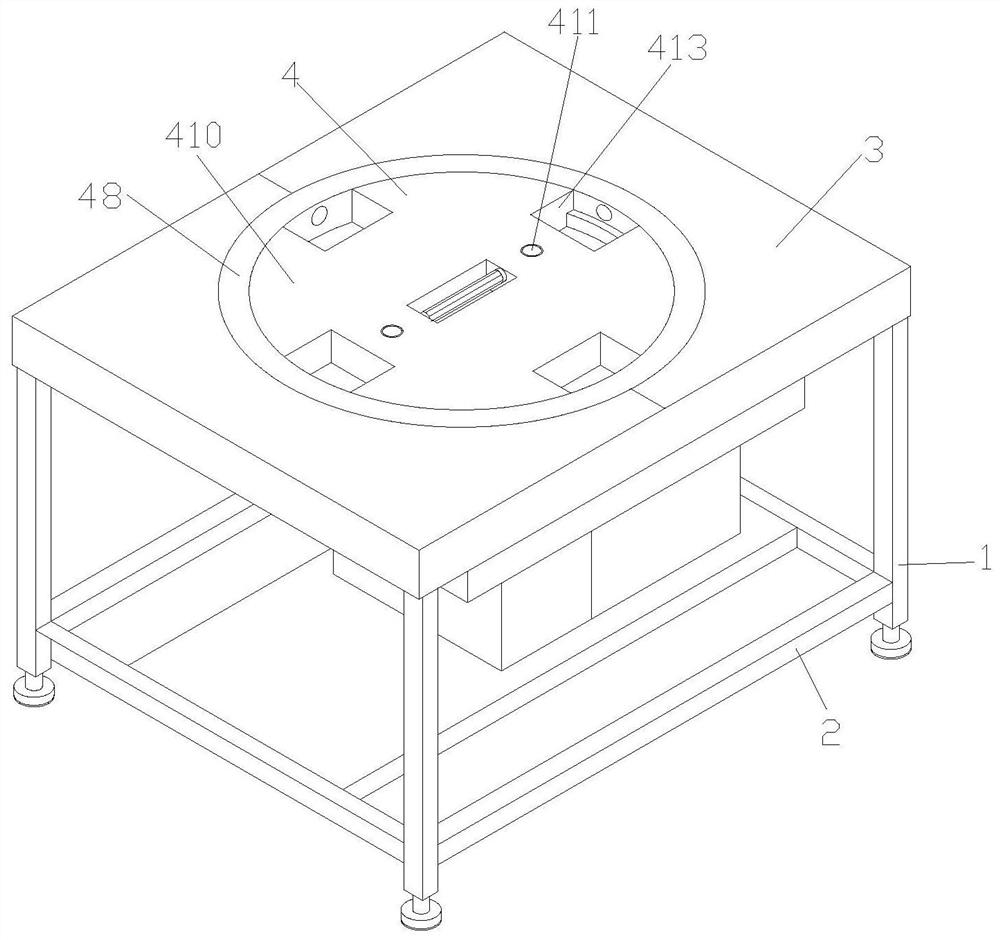

[0026] see Figure 1 to Figure 5 , the present invention provides a multifunctional workbench for mold design through improvement, including a bracket 1 and a reinforcing rod 2, the bracket 1 is installed on the bottom end surface of the workbench 3, and the bottom of the side surface of the bracket 1 is locked with the reinforcing rod 2, which improves the Stability of support 1.

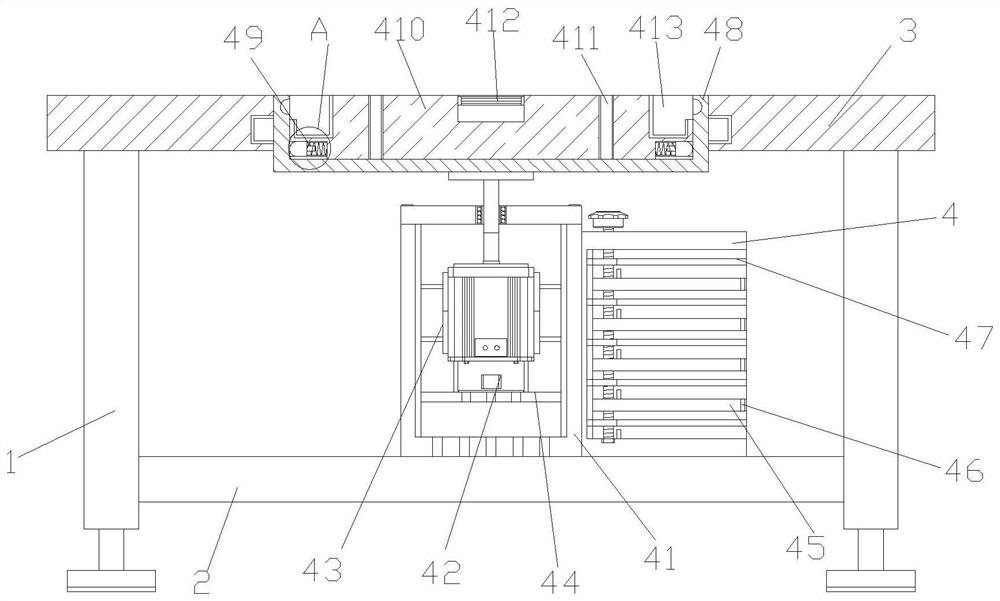

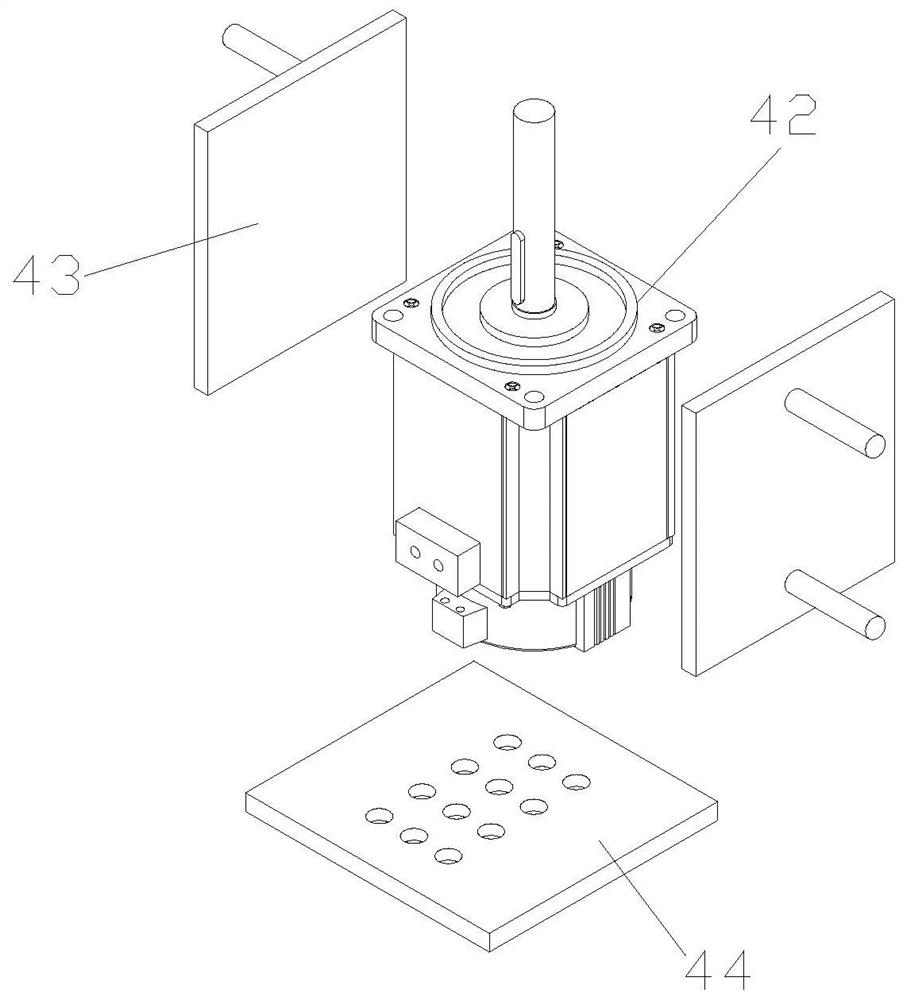

[0027] see figure 2 and image 3 , the present invention provides a multifunctional workbench for mold design through improvement. The rotating mechanism 4 is arranged on the outside of the workbench 3. The rotating mechanism 4 includes a housing 41, a motor 42, a reinforcement frame 43, a bottom plate 44, a partition 45, Label 46, pressing mechanism 47, outer frame 48, fixing mechanism 49, slider 410, guide rod 411, handle 412 and placement groove 413, housing 41 is arranged on the inner bottom end of support 1, the inner left end and right end surface of housing 41 The middle part is hollowed...

Embodiment 2

[0031] The present invention provides a multi-functional workbench for mold design through improvement, four supports 1 are arranged on the bottom end surface of the workbench 3 and four ends, and no two adjacent supports 1 are connected by reinforcing rods 2, so that The workbench 3 is more stable during the placement process. Four reinforcement rods 2 are arranged in a ring shape at the bottom of the workbench 3, and the reinforcement rods 2 at the left and right ends are connected by a square plate, which facilitates the installation of the shell 41 on the top of the square plate .

[0032] The present invention provides a multifunctional workbench for mold design through improvement, and its working principle is as follows;

[0033] First, first place the device as a whole in an appropriate position stably, and connect the motor 42 to an external controller, and then directly carry out corresponding mold design on the top surface of the workbench 3;

[0034] Second, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com