Rolling system and working method thereof

A technology of rolling and rolling machine, applied in grain processing and other directions, can solve problems such as difficulty in adjusting the inclination of the inclined insert plate, and achieve the effects of improving connection strength, high adjustment accuracy and increasing connection area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

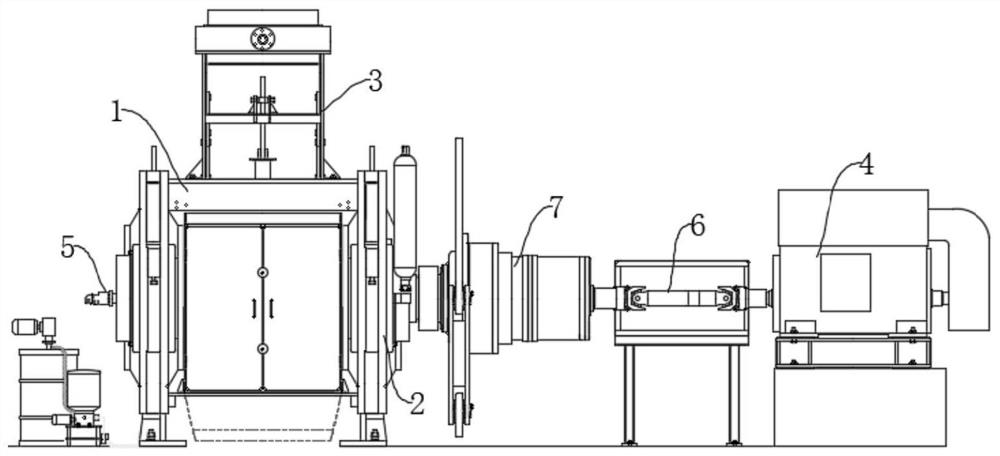

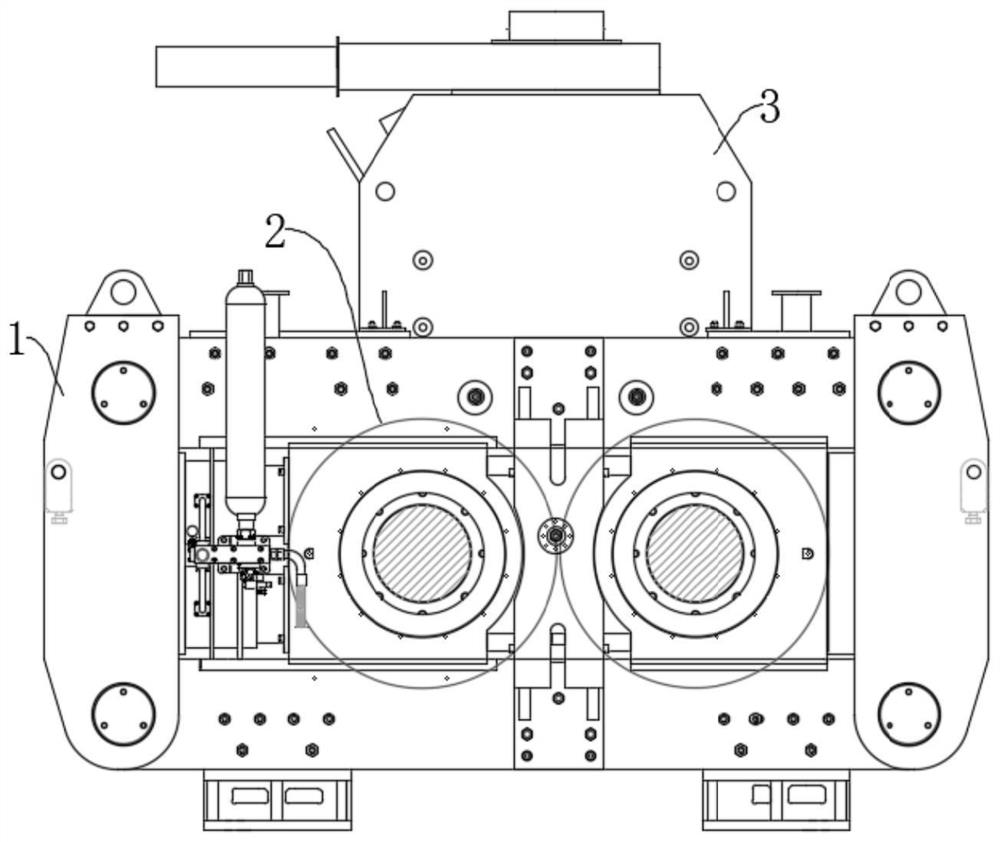

[0039]Such as figure 1 and figure 2 As shown, a rolling system is used to grind materials to a smaller particle size, which includes a rolling machine frame 1, a motor 4, a reducer 7 and a cooling device 5, and the lower part of the rolling machine frame 1 A squeeze roller 2 is provided, and a feeding device 3 is provided on the upper part. The specific structure and working principle of the system will be described in detail below.

[0040] Wherein, the motor 4 and the reducer 7 are power devices for driving the squeeze roller 2 to rotate. The lower part of the motor 4 is provided with a motor seat, and the motor 4 is fixedly arranged on the motor seat. The output shaft of the motor 4 is connected to one of the output shafts of the speed reducer 7 through the transmission shaft 6, and the other output shaft of the speed reducer 7 is connected to the roller shaft of the extrusion roller 2 to control the rotation of the extrusion roller 2. By setting The way of the transmis...

Embodiment 2

[0052] A kind of rolling system working method adopts a kind of rolling system of embodiment 1, and its process is as follows:

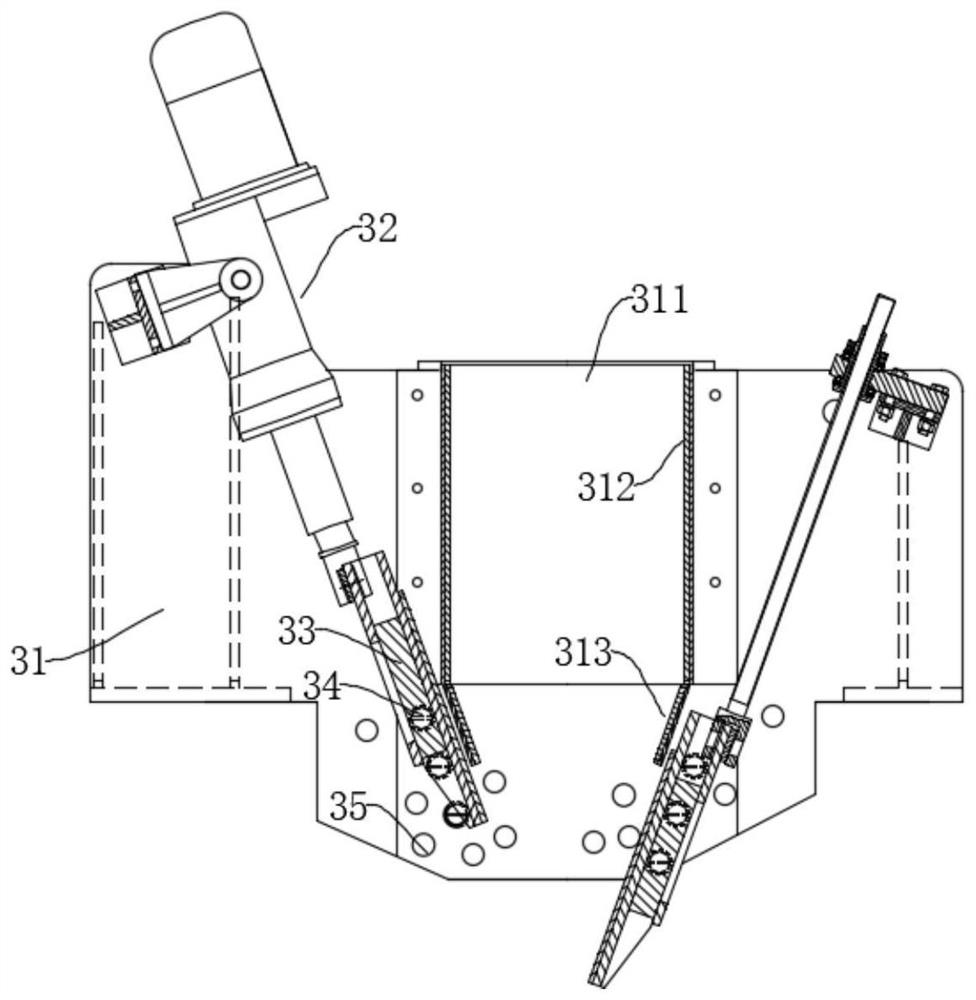

[0053] The telescoping mechanism 32 shrinks the inclined plate 33, and then, according to the set inclination, guide rollers 34 are installed on the corresponding pair of mounting holes 35, and then the telescopic mechanism 32 works to make the upper plate 331 and the lower plate of the inclined plate 33 332 passes through the guide roller 34 that installs. Afterwards, the motor 4 is started, and the material is poured from the feed port 311 of the feed device 3 , and the material falls between the squeeze rollers 2 from the feed device 3 .

[0054] In the working method of the rolling system of this embodiment, by adopting the rolling system of Embodiment 1, the telescopic mechanism 32 only needs to be hingedly arranged with the feeding frame 31, and the inclined plate 33 can be adjusted without disassembling and installing it. The slope has a wide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com