Dismantling tool and online replacement method for fixed end of bolted worm gear and pinion

A replacement method and fixed-end technology, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of time-consuming and labor-consuming, heavy production tasks of sintering machines, and large losses, so as to improve maintenance efficiency, meet assembly technical requirements, and reduce downtime the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

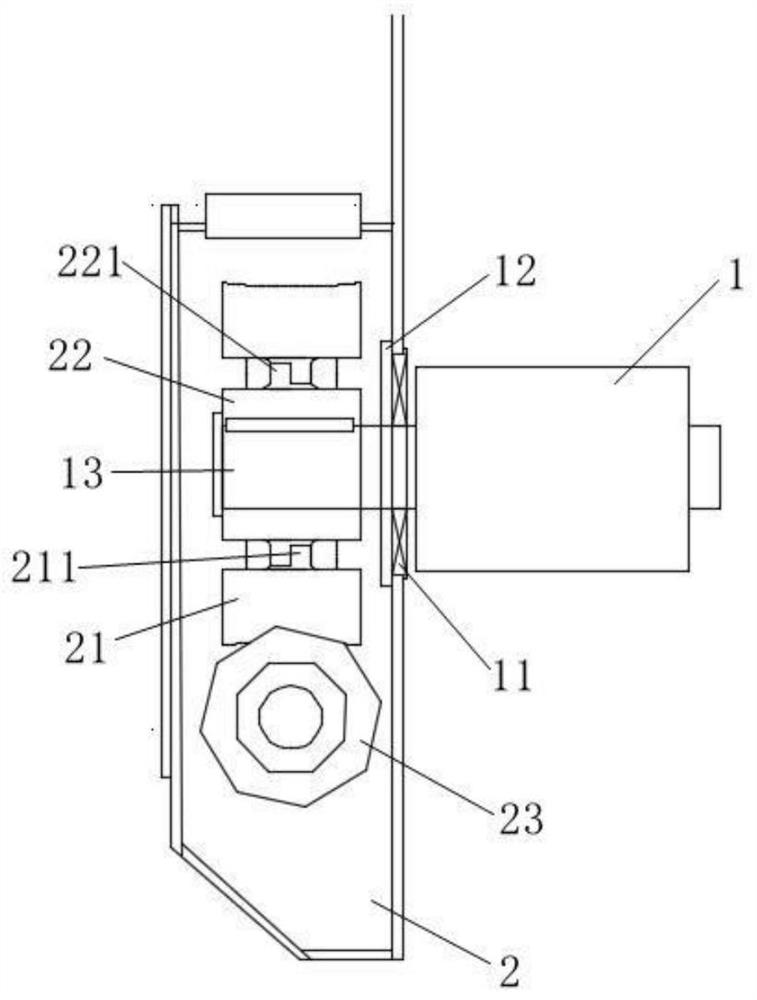

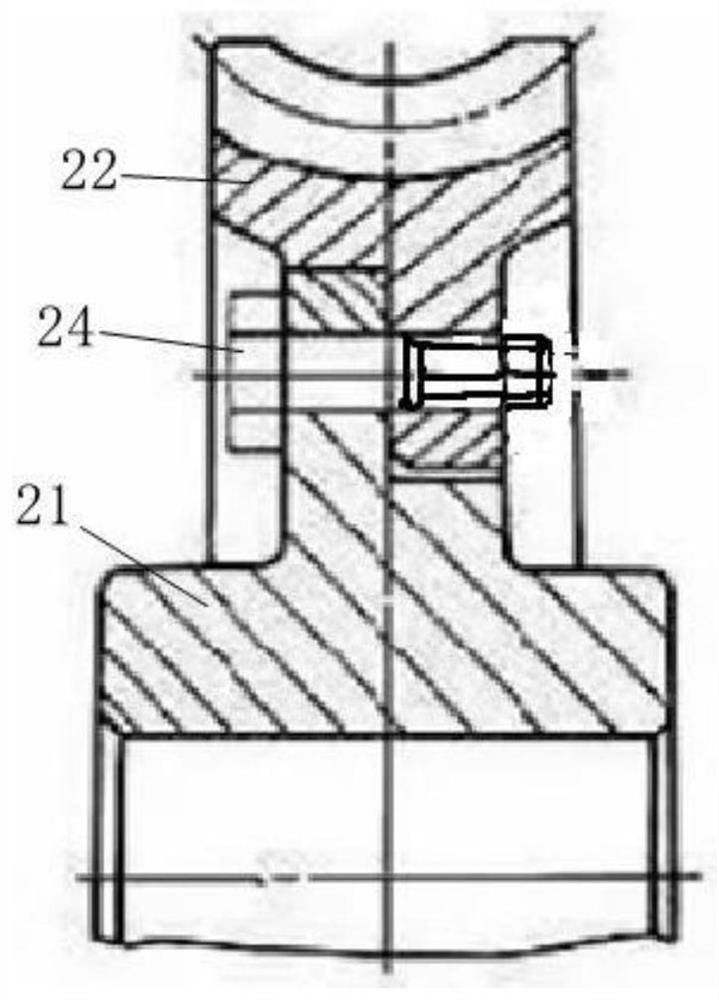

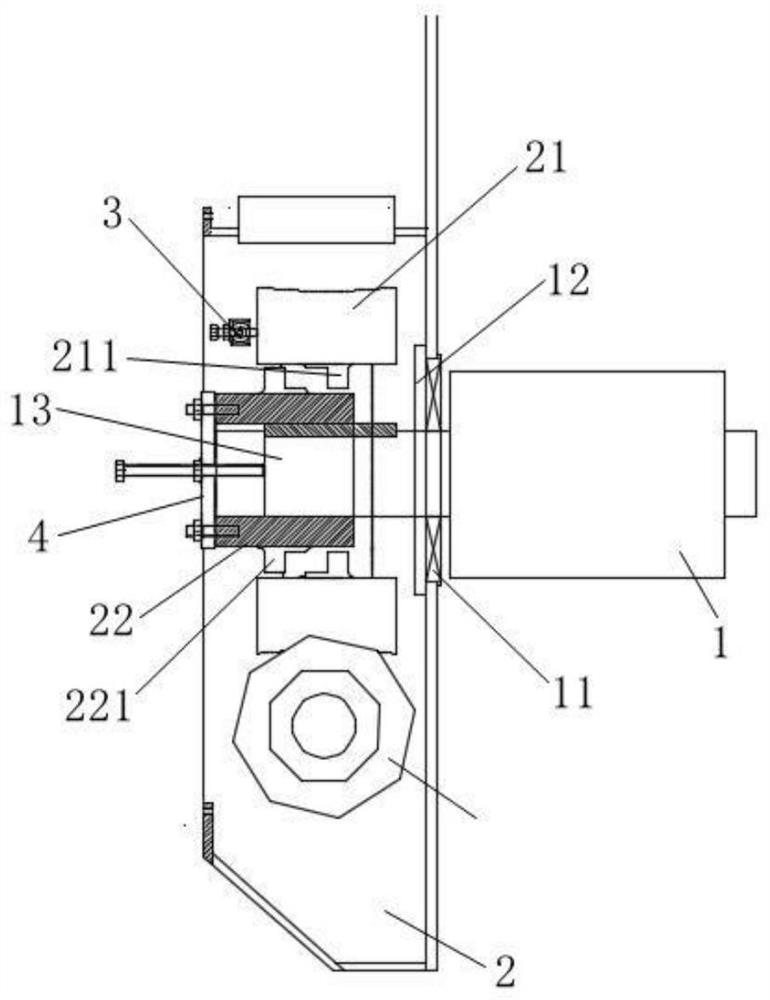

[0037] The dismantling tool for the fixed end of the bolt-connected worm gear pinion, including the ring gear pressure rod 3 supported on the worm gear box 2 and pushing out the worm gear ring gear 21, and the pulling hub device 4 for pulling out the worm gear hub 22;

[0038] The ring gear pressing rod 3 comprises a pressing rod main body 31, two screw rods 32 which are screwed in the horizontal direction at both ends of the pressing rod main body 31, and a pressing rod which is threaded in the vertical direction in the middle of the pressing rod main body 31 and is used to eject the worm gear ring gear 21. Rod screw 33, screw rod 32 is rotatably connected with an inner arc support block 34 for supporting in the worm gear box 2 at one end away from the pressure rod main body 31, the inner arc support block 34 is a permanent magnet, and the outer arc support block 34 The side is a rough friction surface, which is conducive to the fixing of the ring gear pressure rod 3 in the wo...

Embodiment 2

[0041] Such as Figure 4-5As shown, on the basis of Embodiment 1, a pressing plate 35 is provided at the end of the pressing bar screw 33 of the ring gear pressing bar 3 close to the worm gear ring gear 21, and the pressing plate 35 is rotatably connected with the pressing bar screw 33, and the pressing plate 35 is connected to the worm gear Contact with ring 21, increase the force bearing area, avoid the surface of the worm gear ring 21 from being scratched by the pressure rod screw 33, and because the pressure plate 35 is rotatably connected with the pressure rod screw 33, the resistance to rotation of the pressure rod screw 33 is greatly reduced; Such as Figure 6 As shown, on the basis of Embodiment 1, a top plate 44 is provided at one end of the top shaft screw 43 of the pull hub device 4 close to the pinion shaft 13, and the top plate 44 is rotatably connected with the top shaft screw 43, and the top plate 44 is connected to the top shaft screw 43. The pinion shaft 13 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com