Cantilever crane telescopic tower crane with attachment mechanism and working method thereof

A technology of tower cranes and booms, which is applied to tower cranes with telescopic booms and its work fields, which can solve problems such as large stress on the main boom and attachments, large design cross-section of attached struts, and inability of the main boom to move up and down. Wide applicability, reduced mass, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

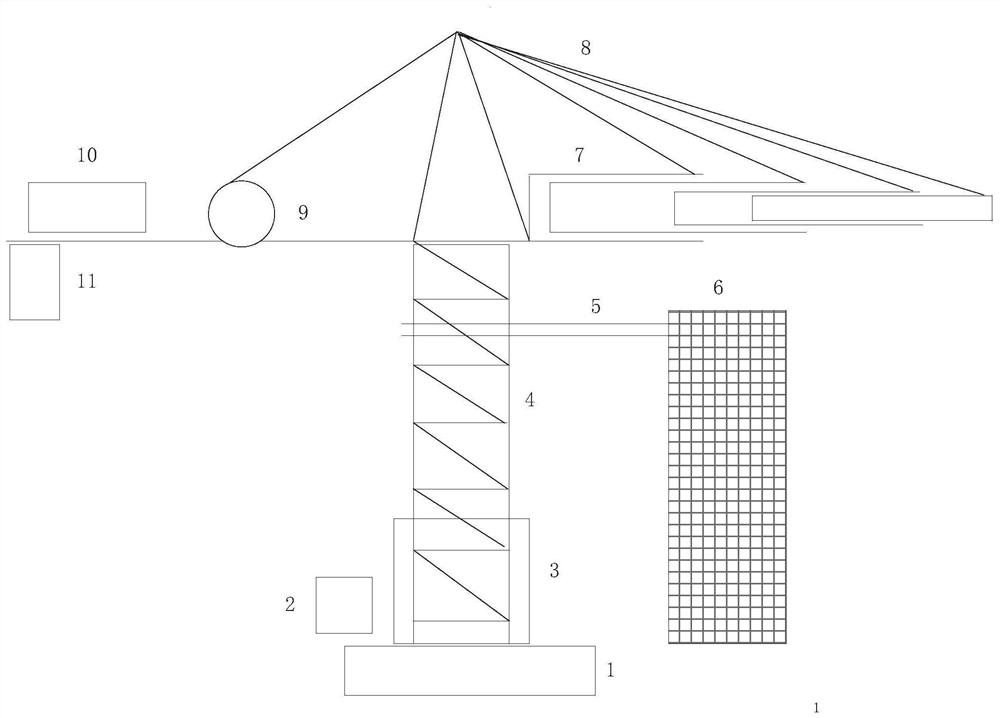

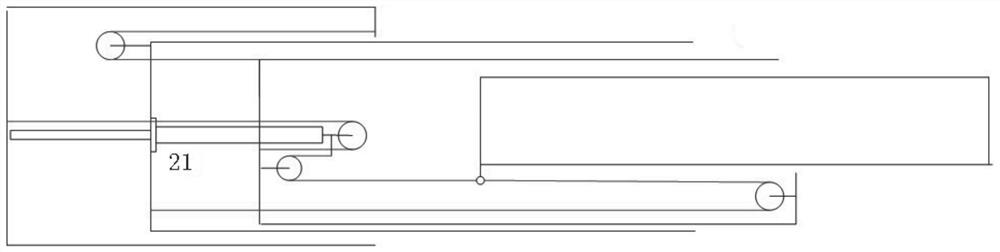

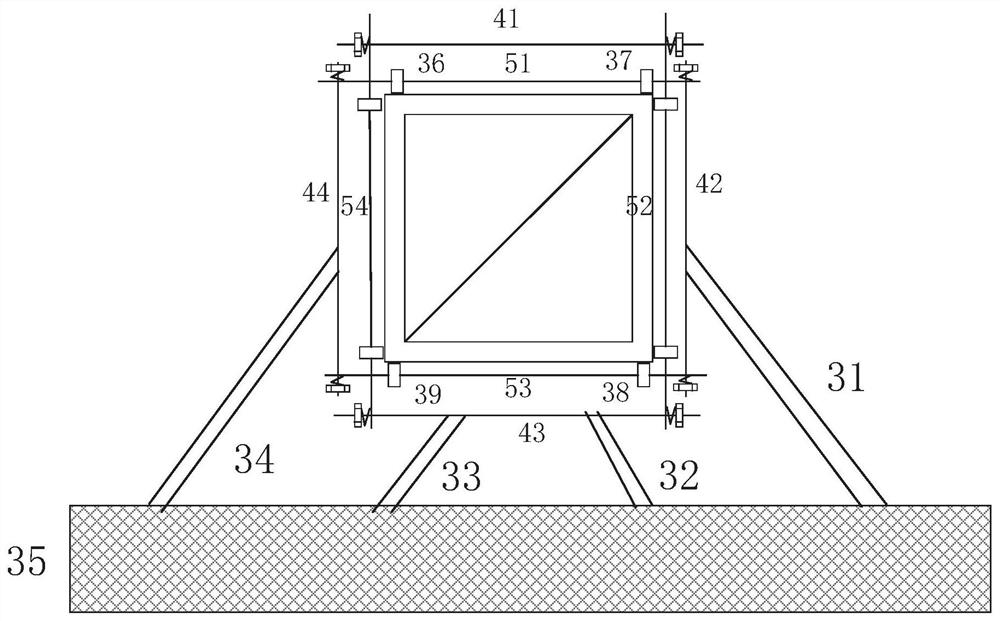

[0019] like figure 1 and figure 2 As shown, the telescopic boom tower crane with an attachment mechanism of the present invention includes a mounting base 1 of the tower crane, a jacking hydraulic pump station 2, a climbing frame 3, a main boom 4, a main boom attachment mechanism 5, a boom main Hoisting 10 and counterweight 11 are characterized in that: the main arm 4 is arranged near the construction building, the main arm 4 is slidably connected with the main arm attachment 6 through the main arm attachment mechanism 5, and the main arm 4 follows the construction of the building The construction increases, while the main arm attachment 6 moves upwards along with the construction of the building, and the stability of the main arm 4 is assisted by the building in construction; the boom is a telescopic boom 7, a telescopic boom 7 is provided with a cable 8 connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com