Sponge city road drainage system

A technology of drainage system and sponge city, applied in the field of municipal construction of sponge city, can solve the problems of affecting traffic, increasing the pressure of urban sewage treatment system, reducing the efficiency of rainwater absorption by sponge city, and achieving the effect of ensuring absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

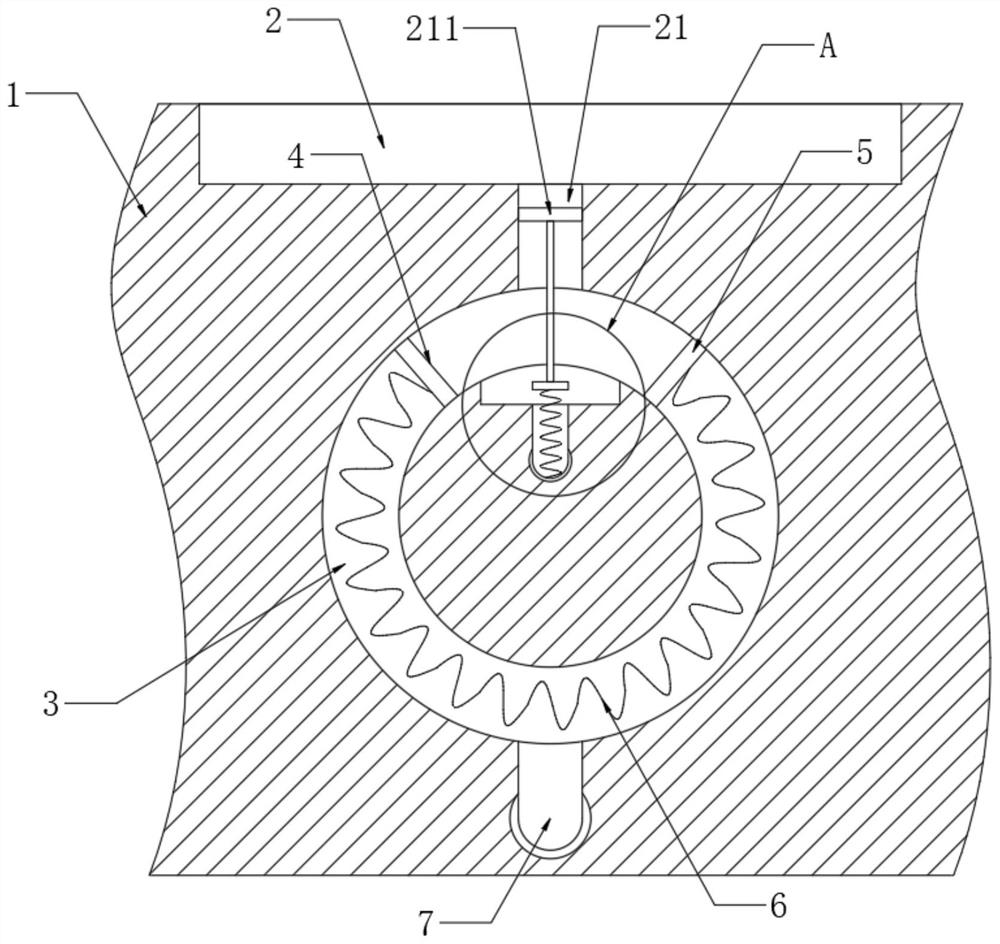

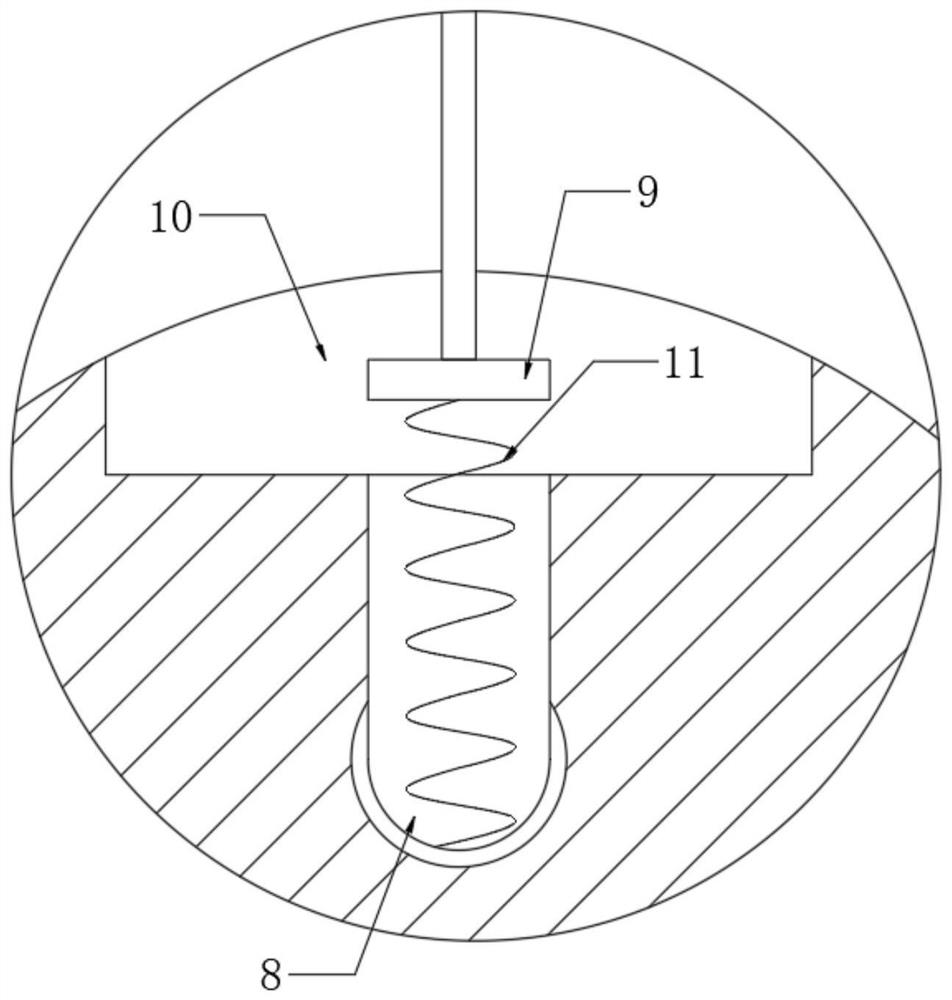

[0023] refer to Figure 1-3 , a sponge city road drainage system, including a drainage channel 2 dug on the subgrade 1, an annular groove 3 is dug under the subgrade 1, and the annular groove 3 and the drainage channel 2 are connected through a diversion channel 21, and the annular groove 3 is slidingly connected with a first baffle 4, and the annular groove 3 is fixedly connected with a second baffle 5, and the first baffle 4 and the second baffle 5 are elastically connected by a first spring 6, and the guide groove 21 A filter screen 211 is embedded in it, an arc-shaped groove 10 is opened on the inner wall of the annular groove 3, a water supply pipe 7 communicating with the annular groove 3 is buried in the roadbed 1, and a sewage discharge pipe communicating with the arc-shaped groove 10 is also embedded in the roadbed 1 The pipe 8 and the arc groove 10 are slidingly connected with a sealing plug 9. It should be noted that after the sealing plug 9 enters the sewage pipe 8...

Embodiment 2

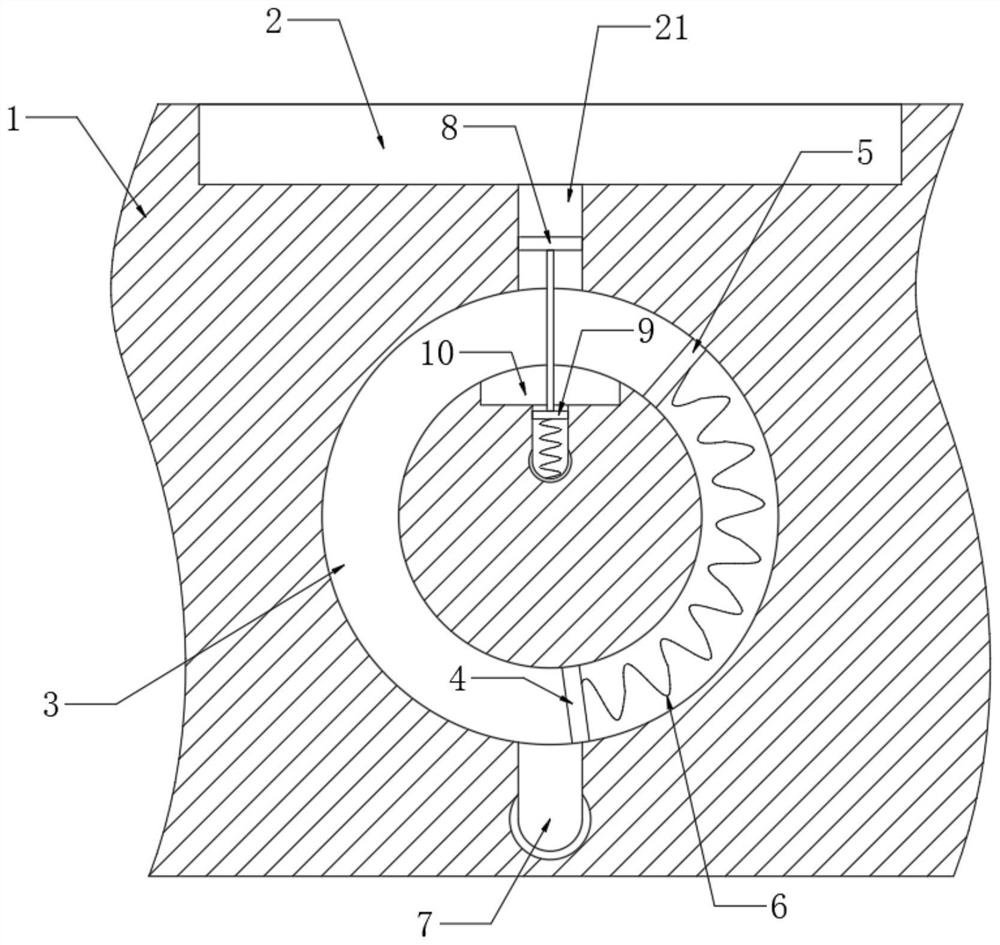

[0026] refer to Figure 4-6 , and the difference from Embodiment 1 is that a storage tank 12 is dug on the subgrade 1, and the storage tank 12 communicates with the diversion tank 21 through the first diversion tank 13, and a scraper is slidably connected in the first diversion tank 13 17. The inner wall of the diversion groove 21 is provided with a second flow diversion groove 14, and a pushing device for pushing the scraper 17 to move is installed in the second flow diversion groove 14.

[0027] The pushing device includes a third spring 15 fixedly connected to the inner wall of the second shunt 14, and the third spring 15 is fixedly connected to the scraper 17, the scraper 17 is made hollow, and an electromagnet 171 is installed in the scraper 17. An iron limiting block 16 is fixedly connected to the inner wall of a splitter groove 13 .

[0028] It should be noted that the iron limit block 16 is set at the notch position of the first splitter groove 13, on the one hand, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com