A wellbore isolation method based on ionic liquid rubber plug

A technology of ionic liquid and magnetic ionic liquid, which is used in earth-moving drilling, sealing/packing, wellbore/well components, etc., which can solve the problems of leakage into the formation, affecting oil and gas production, and difficult to achieve targeted plugging and isolation. , to achieve cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

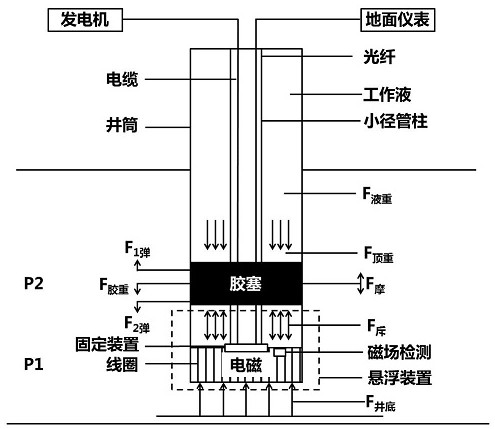

[0049] refer to figure 1 , the present embodiment provides a wellbore isolation method based on a high-strength magnetic ionic liquid rubber plug, comprising the following steps:

[0050] (1) Select a high-strength magnetic ionic liquid rubber stopper. The magnetic properties of the rubber stopper must meet: under the action of the magnetic field, the generated magnetic force is greater than the gravity of the rubber stopper and the upper working fluid; the strength of the rubber stopper must meet: to withstand the upper working fluid and The difference between the acting force of the lower magnetic field; the gelation time of the rubber stopper must meet: the target position is solid, and the magnetic ionic liquid gel preparation method disclosed in the invention patent "A preparation method of magnetic hydrogel (201910206217.0)" can be used , but not limited to this method, in order to achieve the above-mentioned effects, you can choose to increase the concentration of magne...

Embodiment 2

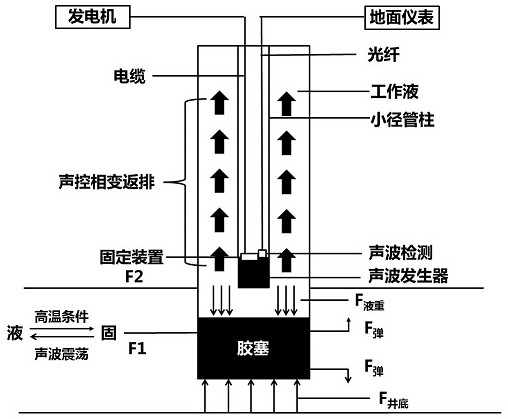

[0068] refer to figure 2 , the present embodiment provides a wellbore isolation method based on a sound-controlled phase-change ionic liquid rubber plug, comprising the following steps:

[0069] (1) Select the sound-controlled phase-change ionic liquid rubber plug. The sound-controlled phase-change ionic liquid rubber plug appears as a liquid with a certain viscosity on the ground, and becomes a gel state under high temperature conditions at the bottom of the well. In order to be a free flowing liquid, the strength of the rubber plug must meet: to withstand the difference between the upper working fluid and the bottom hole pressure; the glue forming time of the rubber plug must meet: the target position is in a jelly state, please refer to the invention patent "A kind of shell". The regenerated hydrogel and its preparation method and application (201911049628.X)” are prepared by the preparation method disclosed in, but not limited to this method, according to the requirements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com