Method for achieving ore transportation through open-pit mine slope adit and vertical shaft truck lifting system

A lifting system and truck technology, applied in mining trucks, transport buses, underground transportation, etc., can solve the problems of reduced system mobility, large space, large engineering volume, etc., and achieve low power and accessories consumption, simple system maintenance, and low cost. The effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0118] The method for realizing ore transportation by the side adit and shaft truck lifting system of the open-pit mine described in the present invention comprises the following steps:

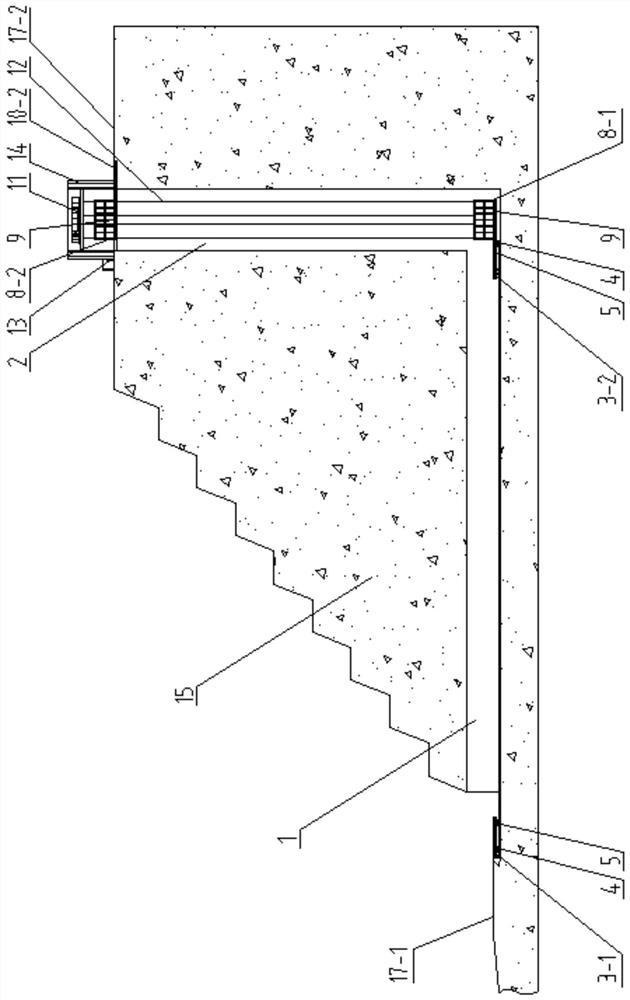

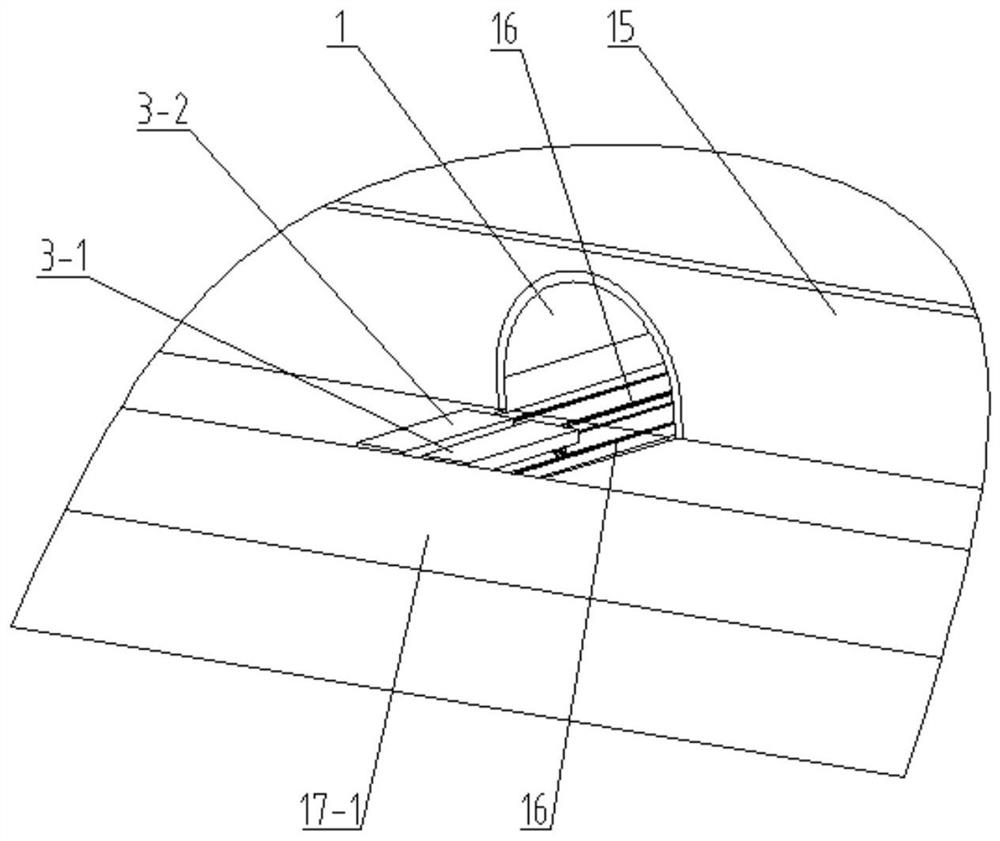

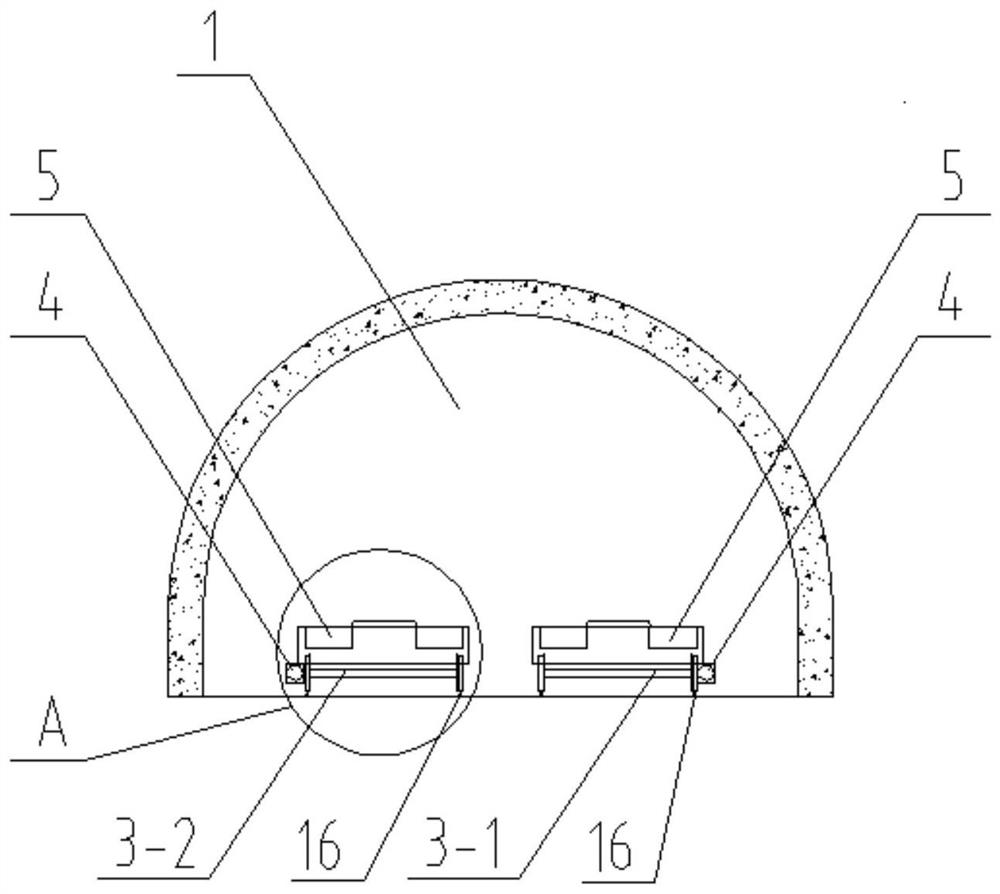

[0119] Step 1, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, an adit 1 is established on the first step at the bottom of the side 15 of the open-pit mine in the vertical direction to the side 15, and the ground of the adit 1 is 1 to 2 steps higher than the lowest level of the bottom of the pit. The section shape of the adit 1 is in the form of an arch, the bottom width of the adit 1 is 13-15m, the vault height of the adit 1 is 8-9m, and the adit body of the adit 1 is supported by reinforced concrete;

[0120] Step 2, continue as figure 1 , figure 2 , image 3 with Figure 4 As shown, a maintenance channel and a truck transport channel are established on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com