Radial flow type turbo expander structure

A turboexpander and radial flow technology, applied in the field of turbines, can solve the problems of sharp changes in blade height, high rotation speed, and long blade, and achieve the effects of low rotation speed, small blade height changes, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

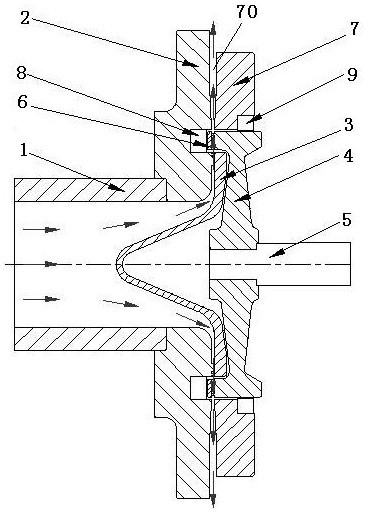

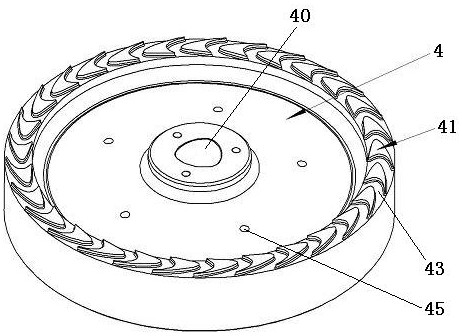

[0021] Please refer to Figure 1 to Figure 3 . According to an embodiment of the present invention, a structure of a radial flow turboexpander includes an intake pipe 1, a static wheel disc 2, a guide cone 3, an impeller 4, a rotating shaft 5, a moving impeller cover 6, an exhaust guide ring 7, Moving impeller cover seal 8 and impeller outer peripheral seal 9.

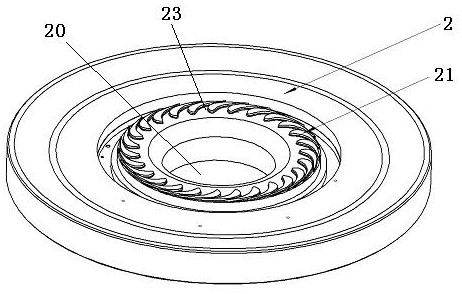

[0022] One end of the intake pipe 1 is connected to the back of the stationary wheel 2, and the connection methods include but not limited to bolt connection, welding and the like. The front of the stationary disc 2 is provided with a plurality of stationary vanes 21 arranged at intervals in the circumferential direction, and the plurality of stationary vanes 21 surround the central through hole 20 of the stationary disc 2, and the gap between each adjacent two stationary vanes 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com