High-energy shot blasting surface hardness numerical simulation method

A surface hardness and numerical simulation technology, which is applied in CAD numerical modeling, electrical digital data processing, special data processing applications, etc., can solve the problems that the surface hardness simulation method has not been reported yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of a high-energy shot peening surface hardness numerical simulation method of the present invention will be further described below by way of example in conjunction with the accompanying drawings. The research material in this example is nickel-based superalloy GH4169.

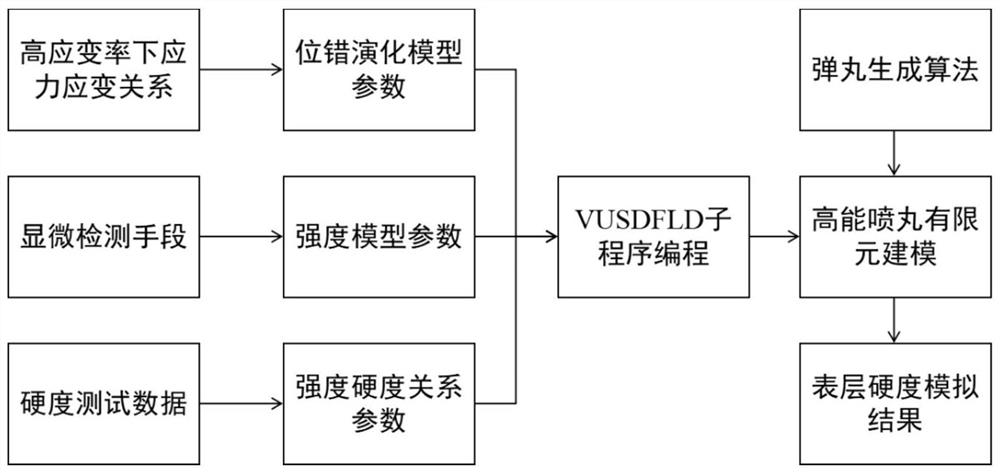

[0027] Such as figure 1 Shown, the concrete realization process of the present invention is as follows:

[0028] The first step is to obtain the dislocation evolution model parameters based on the stress-strain data at high strain rates, establish the dislocation evolution model of the material to be studied, and correlate the grain size, dislocation density and macroscopic stress-strain; the stress-strain data at high strain rates can be It can be obtained by carrying out the Hopkinson compression bar test under high strain rate or according to the established high strain rate constitutive model of the material to be studied, such as the J-C model. This example takes the J-C mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com