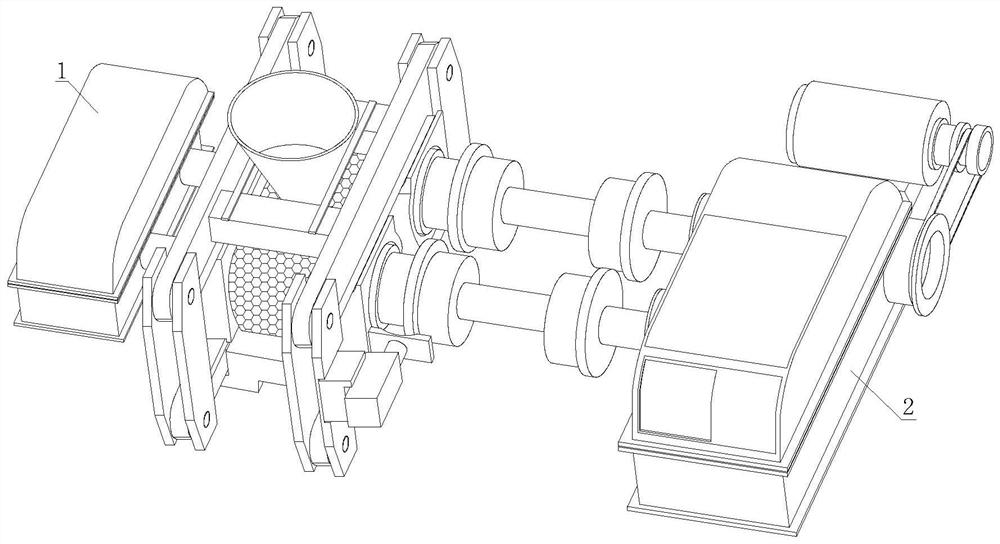

Neodymium iron boron magnetic powder forming die-casting device and implementation method thereof

A neodymium-iron-boron and magnetic powder technology, which is applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of low forming efficiency, difficult to take out forming magnets, easy accumulation of forming magnets, etc. collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

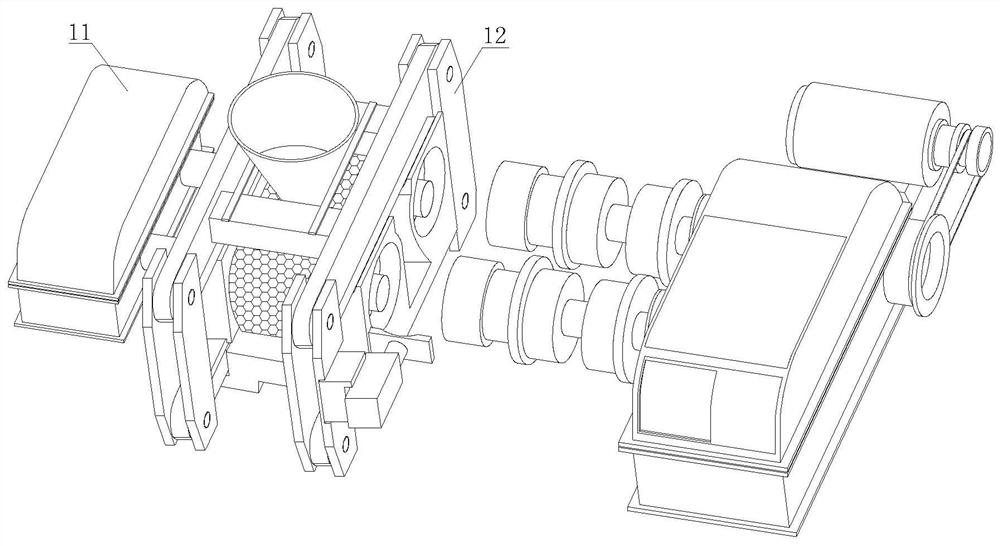

[0039] In order to better demonstrate the implementation process of the NdFeB magnetic powder molding die-casting device, this embodiment now proposes an implementation method of the NdFeB magnetic powder molding die-casting device, including the following steps:

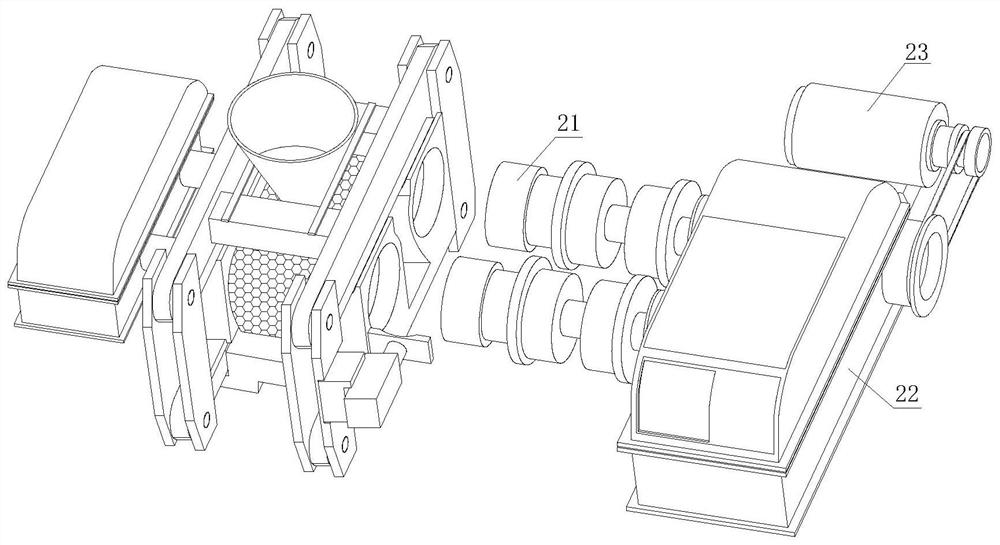

[0040] Step 1: Pour the NdFeB magnetic powder raw material to be processed into the molding cavity 123 through the feeding funnel 1231, and open the hydraulic cylinder 22, and drive the cylinder ejector rod 212 to move through the hydraulic cylinder 22, and at the same time drive the pressure column 211 to approach the through hole 12231;

[0041] Step 2: continue to drive the pressing column 211 to move forward at high speed, and align the pressing block 2111 with the through hole 12231 and further extend into the inner cavity of the working cavity 1223 and the molding cavity 123 to carry out high-speed stamping of the NdFeB magnetic powder raw material;

[0042] Step 3: After the die-casting is completed, shrink t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com