Method and system for earth leakage protection of mine-used variable frequency drive system

A leakage protection, variable frequency drive technology, applied in the direction of automatic disconnection emergency protection devices, emergency protection circuit devices, electrical components, etc., can solve the problems of reduced sensitivity, loss of grading protection, low insulation, etc., to improve safety and reliability. the effect of improving safety

Active Publication Date: 2022-06-03

TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

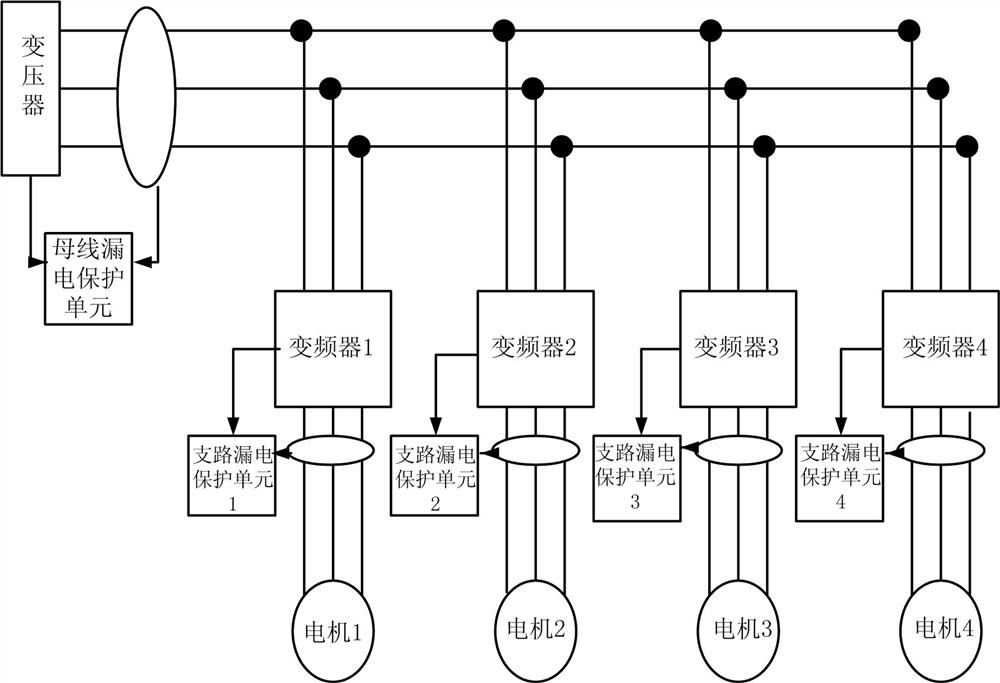

[0002] With the promotion and use of frequency conversion drive systems in coal mines, especially on airborne equipment, coal shearers, continuous miners, shuttle cars, and bolters mostly use frequency conversion traction systems. Due to the traditional leakage protection system, there must be a grounding resistance. , resulting in only one set of leakage protection at the back end of the entire transformer. If there are multiple sets, they will inevitably affect each other and cannot work normally.

That is, at the back end of the transformer, all electrical equipment share a set of leakage protection, and the insulation status of other electrical equipment is completely dependent on it, which loses the meaning of hierarchical protection. If the insulation to the ground is low, it is difficult to accurately locate point of failure

For the AC power supply system, the current conventional detection principle in coal mines is zero-sequence voltage current and additional DC method. For standard power frequency electrical equipment, its performance can be fully satisfied, but for variable frequency drive devices, due to the existence of high frequency leakage current, Its zero-sequence voltage and current detection method does not work properly

The additional DC detection method can be barely used, but for the high-power four-quadrant variable frequency drive device, which often malfunctions, it can only be barely used by reducing the sensitivity.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

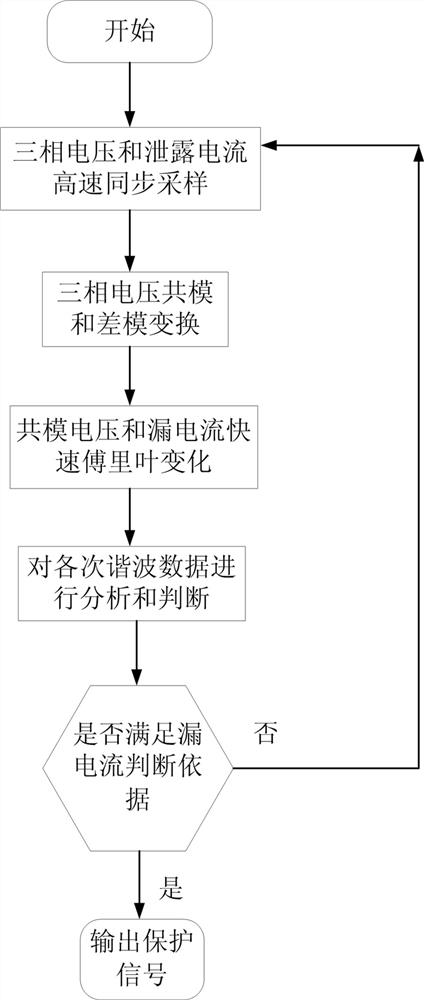

[0034]; (1)

[0038]; (2)

[0039]; (3)

[0041] S4, leakage judgment.

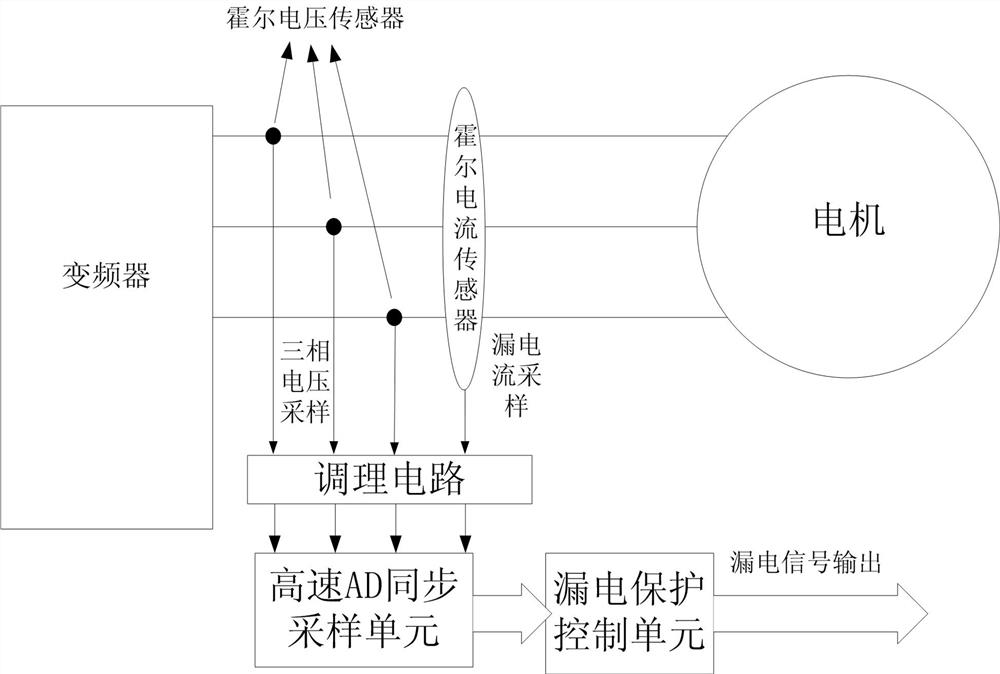

[0046] Wherein, the leakage protection control unit is used for outputting the leakage protection signal according to the signal collected by the acquisition unit.

[0047] Specifically, in this embodiment, the sampling rate of the AD synchronous sampling unit is greater than 10M.

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of frequency conversion drives for mines, and discloses a leakage protection method and system for a frequency conversion drive system for mines. The method includes the following steps: S1, four-way synchronous sampling of the three-phase output voltage of the frequency converter and the ground leakage current ; S2, performing common-mode transformation on the measured three-phase voltages to obtain common-mode voltage values; S3, performing Fourier transformation on common-mode voltages and common-mode currents to obtain harmonic voltages and harmonic currents, wherein Fourier The frequency upper limit of the leaf transformation is set as the switching frequency of the frequency converter; S4, all harmonic signals whose voltage amplitude is less than the voltage threshold or the current amplitude is less than the current threshold are discarded; and then among the remaining harmonics, successively calculate the If the phase difference between the harmonic voltage and the harmonic current is within ±10°, it is determined that the resistive circuit is the main component, and the leakage protection signal is output. The invention realizes the function of hierarchical leakage protection and improves the safety and reliability of the variable frequency drive system used in mines.

Description

A leakage protection method and system for a mining variable frequency drive system technical field The invention belongs to the field of mining variable frequency drive systems, and in particular relates to a leakage protection method for mining variable frequency drive systems laws and systems. Background technique [0002] With the popularization and use of the frequency conversion drive system in coal mines, especially on airborne equipment, shearers, continuous miners, shuttles, Most bolters use variable frequency traction system. Due to the traditional leakage protection system, there must be a grounding resistance, which leads to There can only be one set of leakage protection at the back end of the entire transformer. If there are multiple sets, they will inevitably affect each other and cannot work normally. that is At the back end of the transformer, all electrical equipment share a set of leakage protection, and the insulation state of other electrical equi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02H3/34H02H7/10

CPCH02H3/34H02H7/10Y02E40/40

Inventor 曹建文姜铭田克君王健王涛张爱荣胡文芳布朋升许连丙程俊强

Owner TAIYUAN INST OF CHINA COAL TECH & ENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com