Cyanamide compound-Pt-based nanocrystalline catalyst as well as preparation method and application thereof

A nanocrystal and compound technology, which is applied in the field of cyanamide compound-Pt-based nanocrystal catalyst and its preparation, can solve the problems of difficult separation of inhibitors, loss of catalyst activity, complex reaction system, etc., and achieves uniform morphology and influence on activity. The effect of small size and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

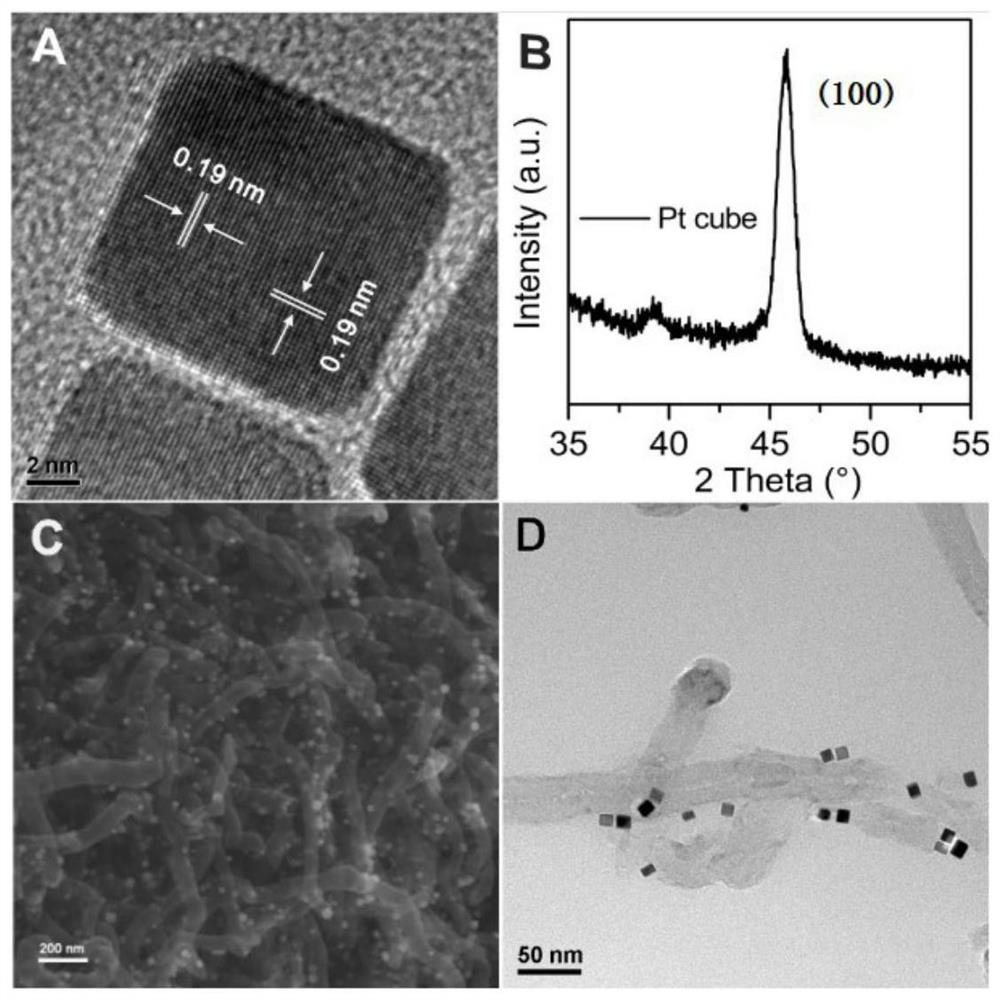

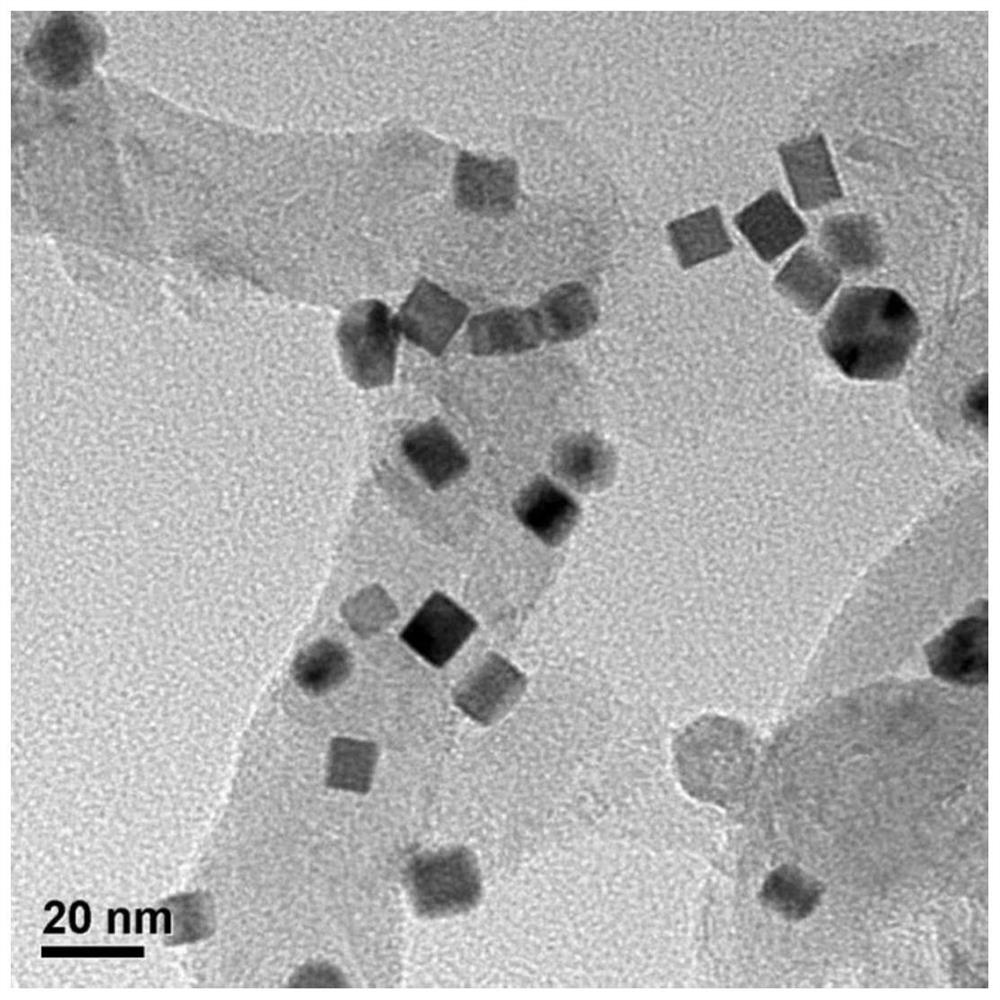

[0034] Preparation of Dicyandiamide-Pt-Based Nanocrystalline Catalyst (The molar ratio of dicyandiamide to Pt-based nanocrystals is 1:1)

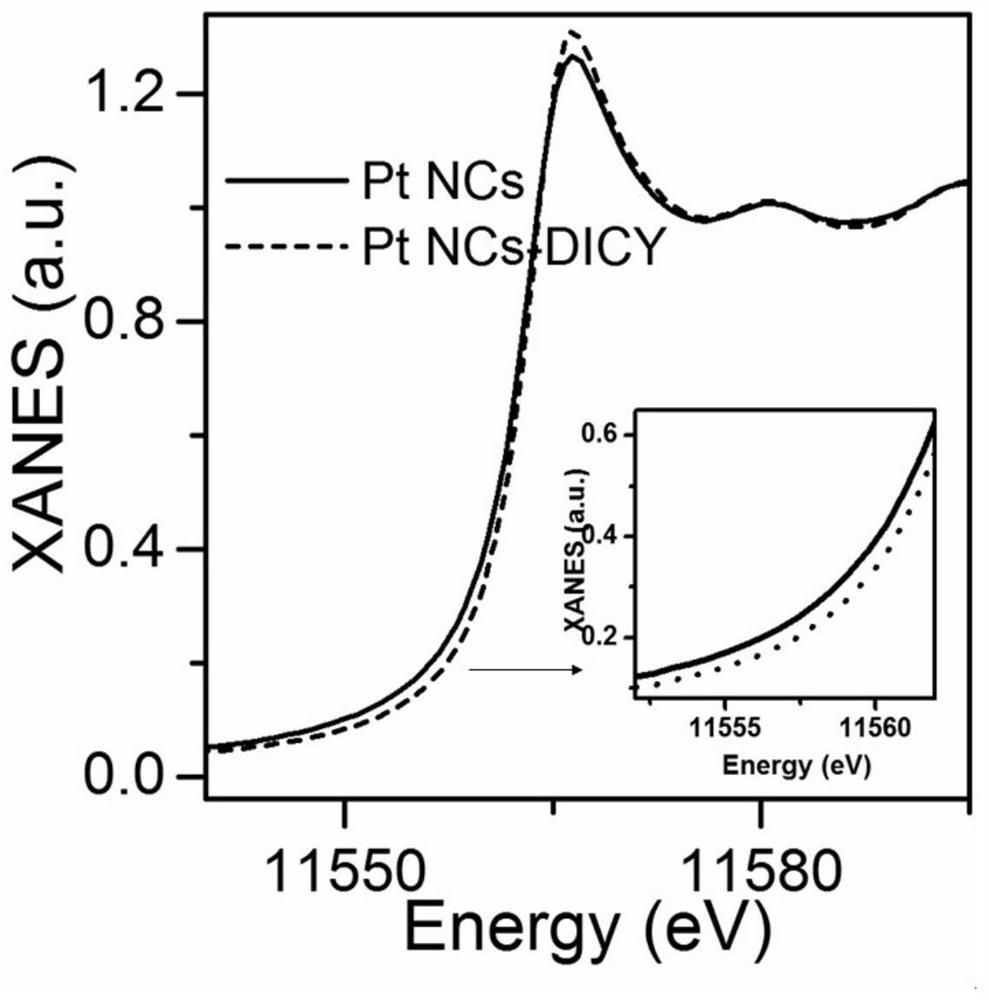

[0035] According to the method provided by the present invention, get clean Pt-based nanocrystals and disperse them in ethanol solution, and add Dicyandiamide solution was modified at 80° C. for 8 hours. The modified catalyst obtained in this example was dicyandiamide-Pt-based nanocrystalline catalyst (1:1).

[0036] Hydrogenation Catalytic Efficiency

[0037] The performance evaluation of the catalyst prepared in this example was carried out. Add 1mmol of 4-nitrochlorobenzene, 0.5mg of the dicyandiamide-Pt-based nanocrystalline catalyst (1:1) of Example 1 and 10mL of absolute ethanol into the reactor in sequence, and feed nitrogen into the reactor for 3 consecutive replacements Air in the reaction kettle, then feed hydrogen into the reaction kettle, start stirring when the pressure in the kettle is 0.1MPa, the rotation speed is 750rp...

Embodiment 2

[0039] Preparation of cyanamide-Pt-based nanocrystalline catalyst and its hydrogenation catalytic efficiency (The molar ratio of cyanamide to Pt-based nanocrystals is 1:1)

[0040] This example adopts the preparation reaction conditions similar to Example 1, and the only difference from Example 1 is that the cyanamide compound used in the reaction is cyanamide, and the modified catalyst obtained in this example is cyanamide-Pt based Nanocrystalline catalyst (1:1). The catalytic reaction conditions of this embodiment are also the same as that of Example 1.

Embodiment 3

[0042] Preparation of melamine-Pt-based nanocrystalline catalyst and its hydrogenation catalytic efficiency (The molar ratio of melamine to Pt-based nanocrystals is 1:1)

[0043] This embodiment adopts the preparation reaction conditions similar to Example 1, and the only difference from Example 1 is that the cyanamide compound used in the reaction is melamine, and the modified catalyst obtained in this embodiment is a melamine-Pt-based nanocrystalline catalyst ( 1:1). The catalytic reaction conditions of this embodiment are also the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com