Aluminum casting solution conveying system

A delivery system and solution technology, applied in the field of aluminum casting, can solve the problems of smaller inner diameter of metal pipes, lower efficiency of molten aluminum, solidification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

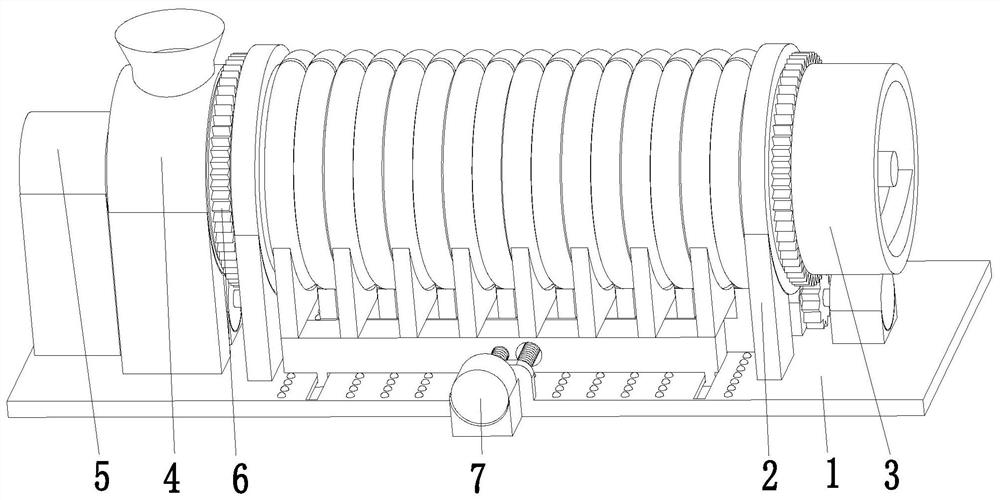

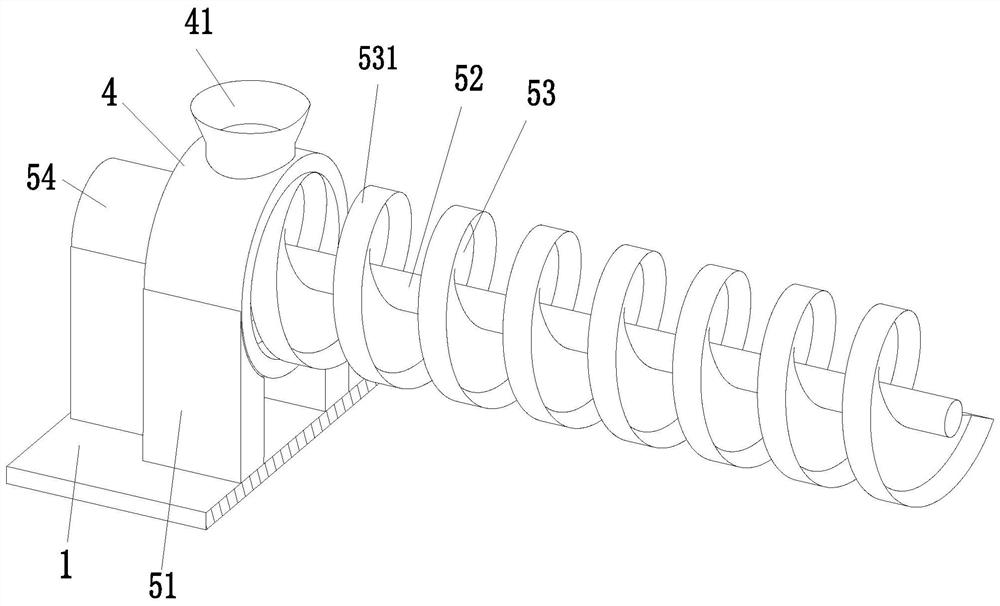

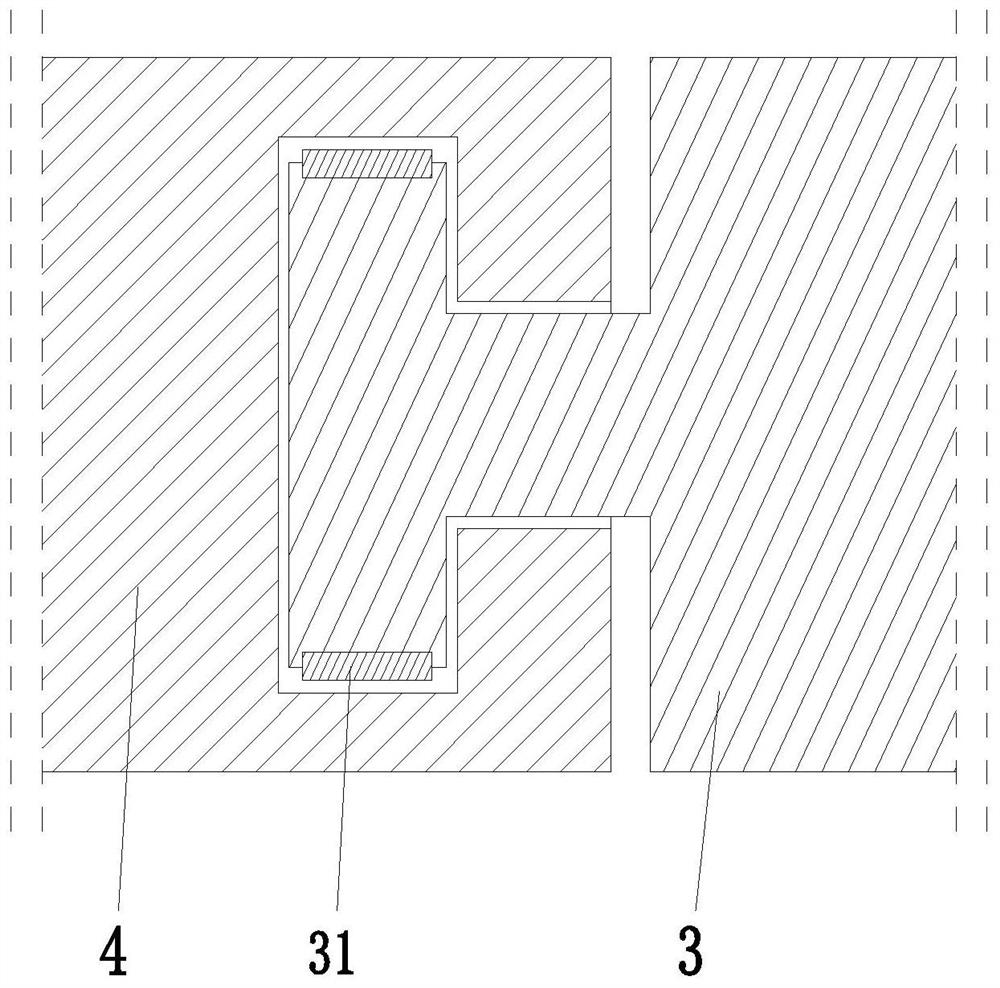

[0033] Such as Figure 1 to Figure 8 As shown, in order to solve the above problems, the present invention provides an aluminum casting solution delivery system, including a base 1, a mounting frame 2, an infusion cylinder 3, a receiving cylinder 4, a stirring mechanism 5, a rotating mechanism 6 and a heating mechanism 7. An installation frame 2 is symmetrically installed on the upper end surface of the base 1. The upper end of the installation frame 2 is a ring structure. The infusion cylinder 3 is installed between the installation frames 2 through rotation and cooperation. The inf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap