Automatic welding equipment for wiring terminal of coil of motor

A coil wiring and automatic welding technology, which is applied to welding equipment, metal processing equipment, and printed circuit assembly of electrical components, can solve the problems of unguaranteed product yield, high labor cost, and defective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

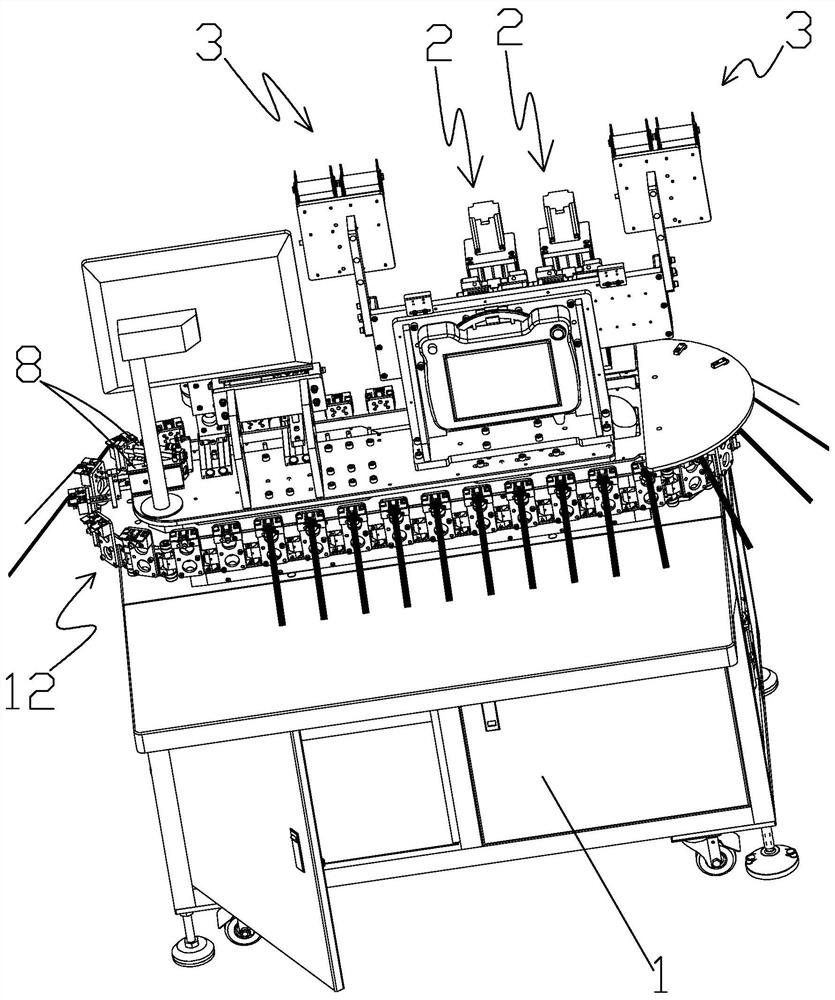

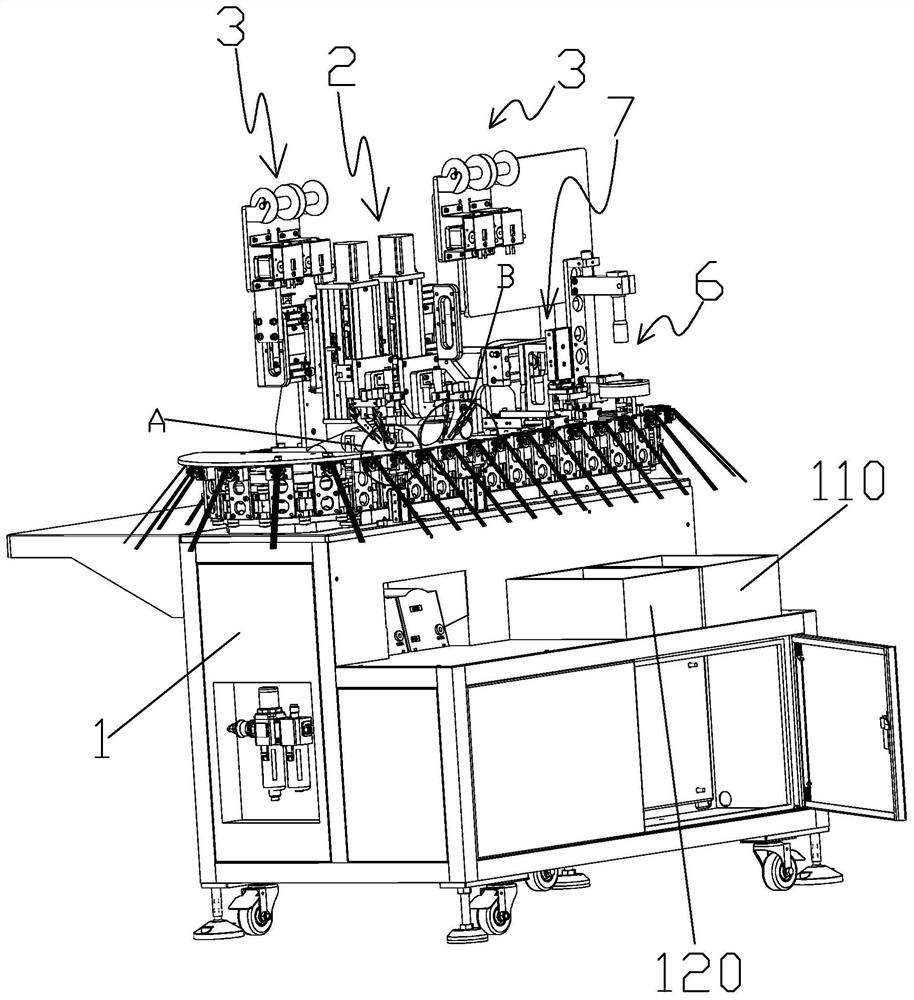

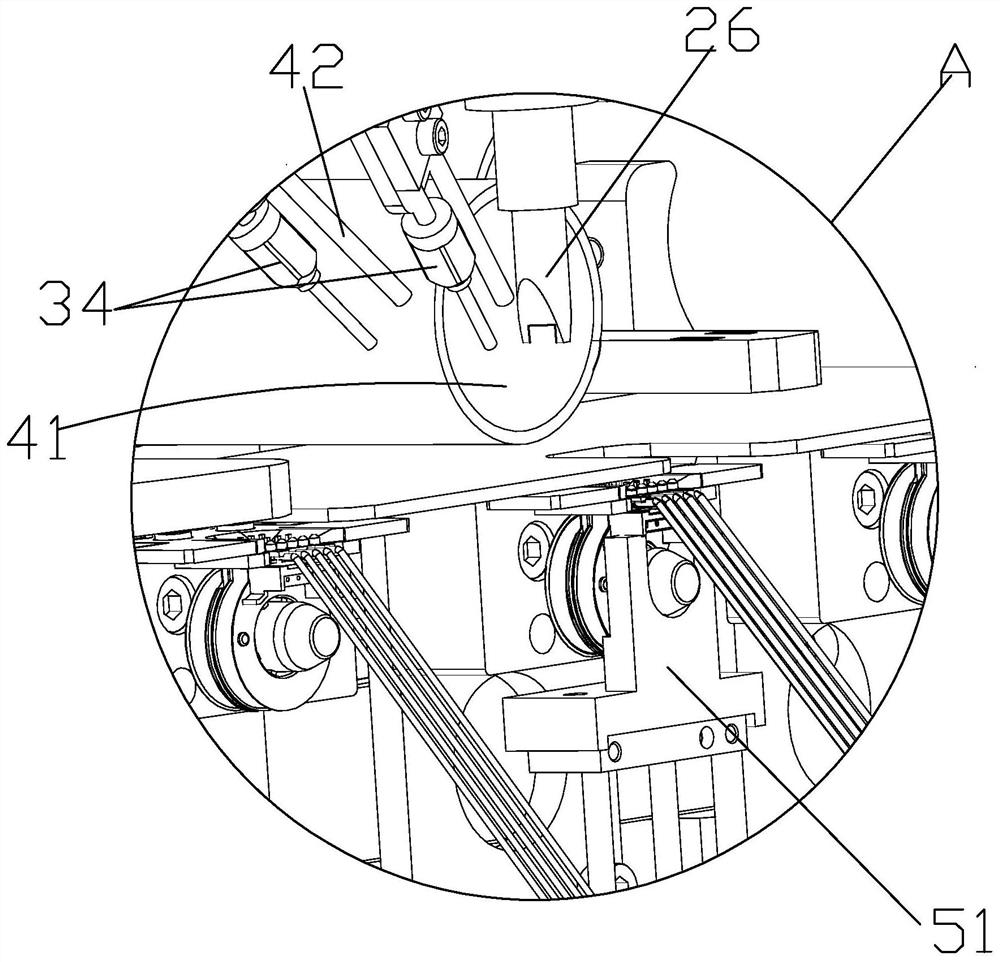

[0038] Attached below Figure 1-14 Embodiments of the present invention will be described in detail.

[0039] like Figure 1-14 As shown, an automatic welding equipment for motor coil terminals in the present invention includes a frame 1, a support base 11 is provided on the frame 1, and a rotary table capable of rotating relative to the support base 11 is connected to the support base 11 12. The rotary table 12 is provided with multiple sets of clamping tooling 13 for clamping the coil frame 101 of the stator assembly 100, and the frame 1 is provided with a driving device 14 capable of driving the rotary table 12 to rotate; On the frame 1 and beside the rotary table 12, there is a welding device 2 that can weld the pins 102 on the stator assembly 100 and the circuit board 103 sleeved on the pins 102 together. And be provided with the tin wire feeding device 3 that is used for supplying tin wire to welding device 2 next to welding device 2, be provided with for unloading the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com