PCB clamping and fixing device for welding maintenance of electronic components

A PCB board and electronic vitality technology, applied in the field of PCB board clamping and fixing devices, can solve the problems of inability to flip and adjust the PCB board, small application range, and poor adjustment performance, so as to improve installation and maintenance welding operations, and improve clamping and fixing Strength and stability, good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

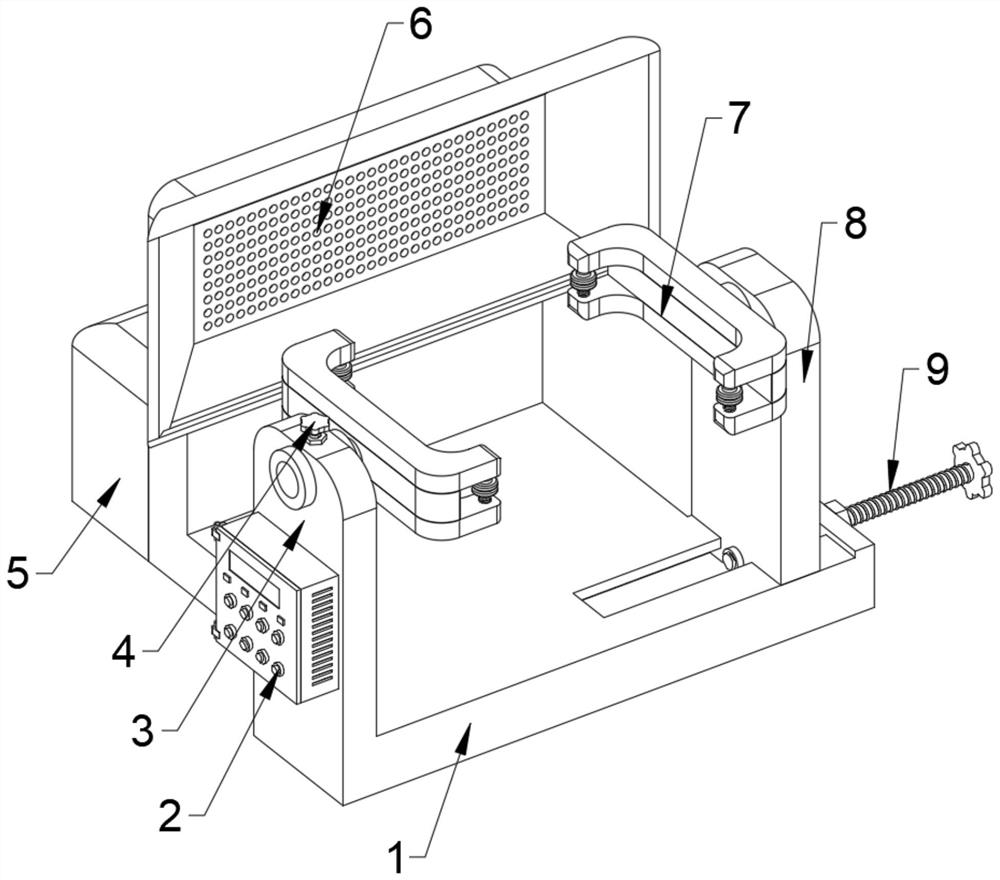

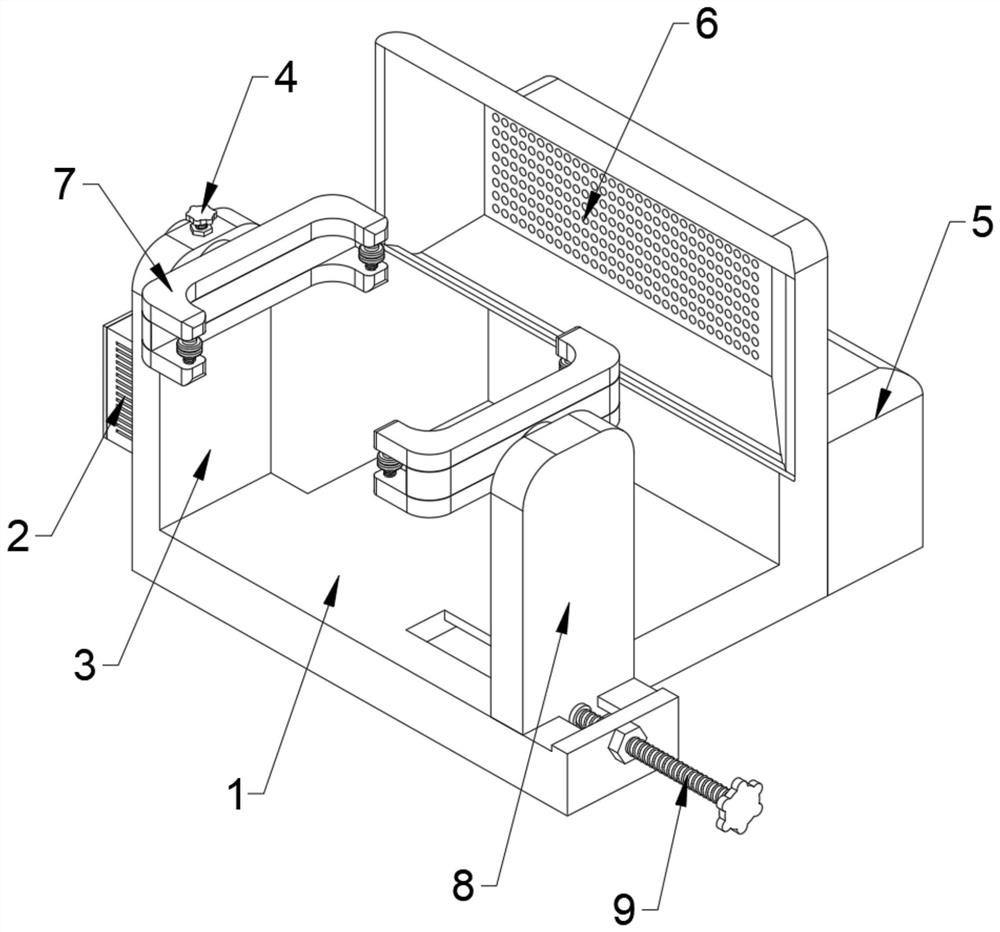

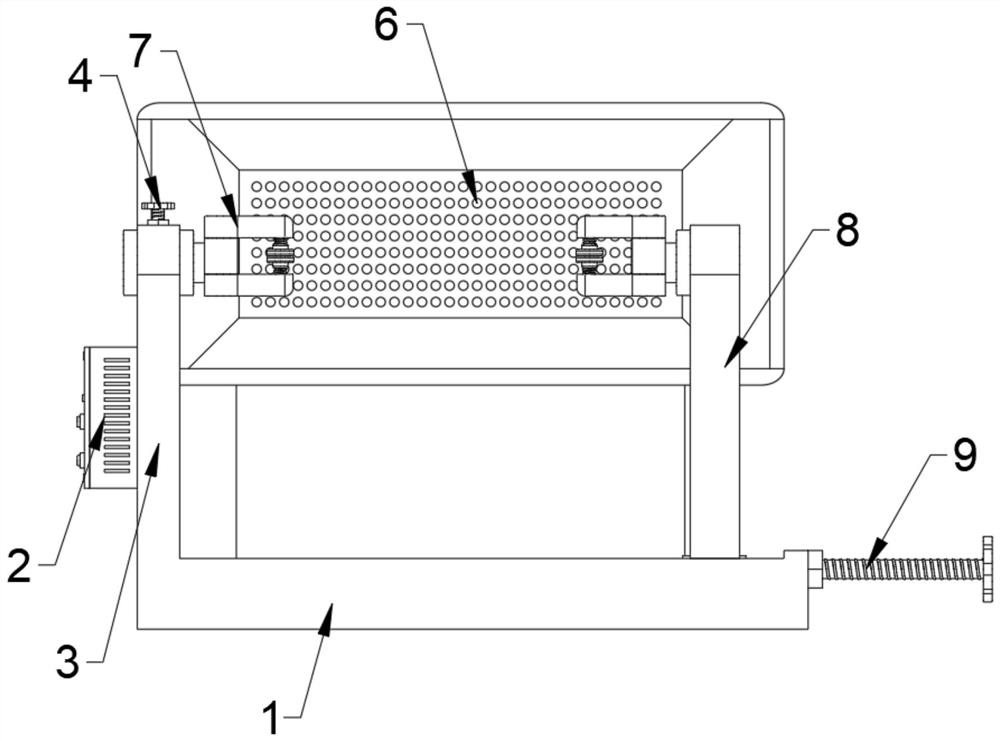

[0038] as attached figure 1 To attach Figure 8 Shown:

[0039]The invention provides a PCB board clamping and fixing device for welding and maintenance of electronic components, including: a base 1, a control box 2, a static support arm 3, a rotating locking handle 4, a smoke purifier 5, and a smoke Absorption plate 6, fixed grip 7, dynamic grip 701, dynamic grip limit block 701a, rubber clamping block 702, buffer spring 702a, static grip 703, electromagnetic adsorption block 704, limit card slot 704a, dynamic support arm 8 and Dynamic support arm adjustment handle 9; the upper left side of the base 1 is fixedly provided with a static support arm 3, and the bolt on the outer wall of the static support arm 3 is equipped with a control box 2; the upper end of the static support arm 3 is pivoted to rotate A fixed grip 7 is installed, and the fixed grip 7 is composed of four parts: a dynamic grip 701, a rubber clamping block 702, a static grip 703, and an electromagnetic adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com