Processing technology of cloud flow line plastic product taking ABS as base material

A technology of ABS plastics and plastic products, which is applied in the field of processing technology of cloud flow pattern plastic products, can solve the problems of unfavorable production, influence, and incapable of quantitative filling, etc., and achieve the effect of improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

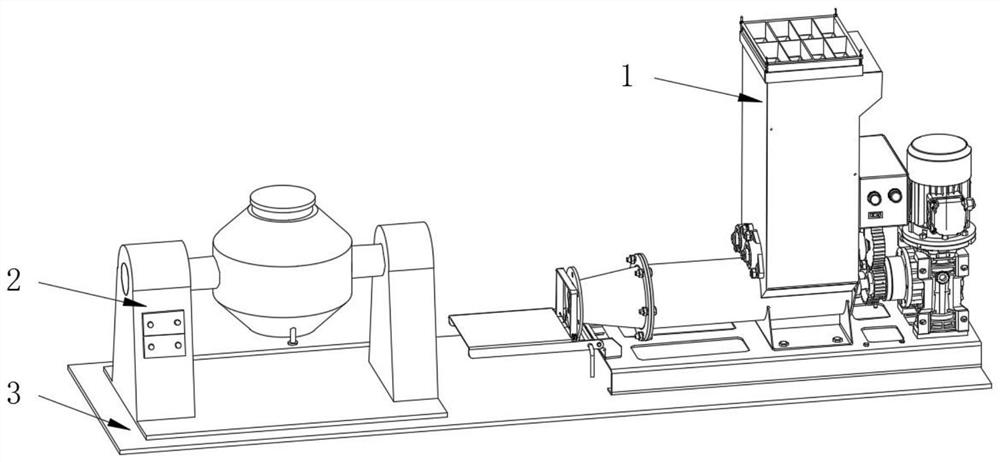

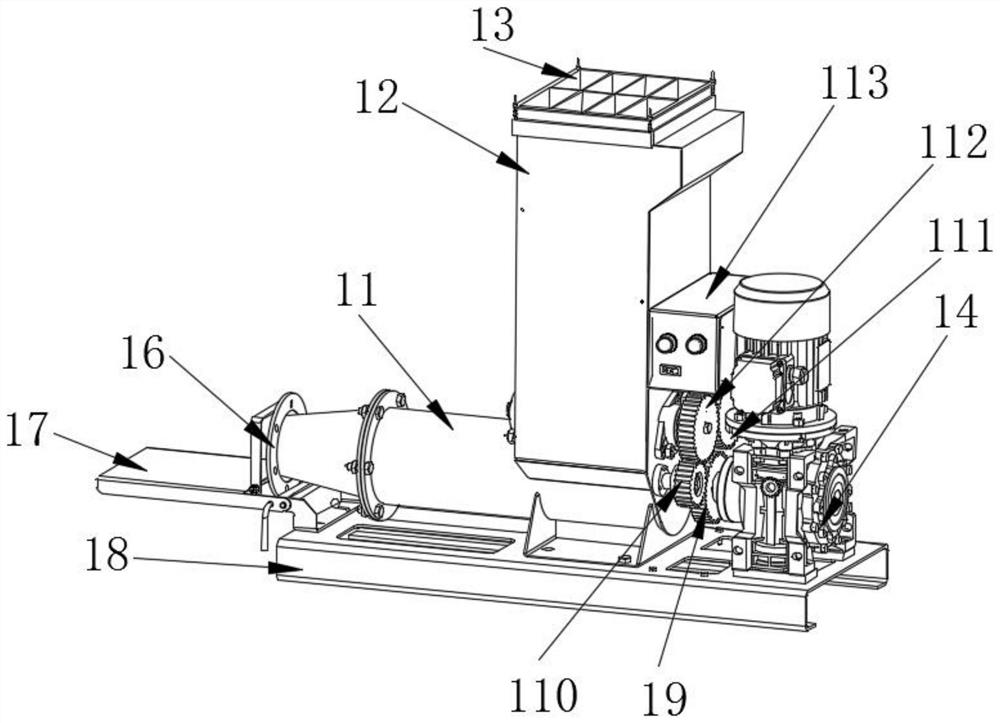

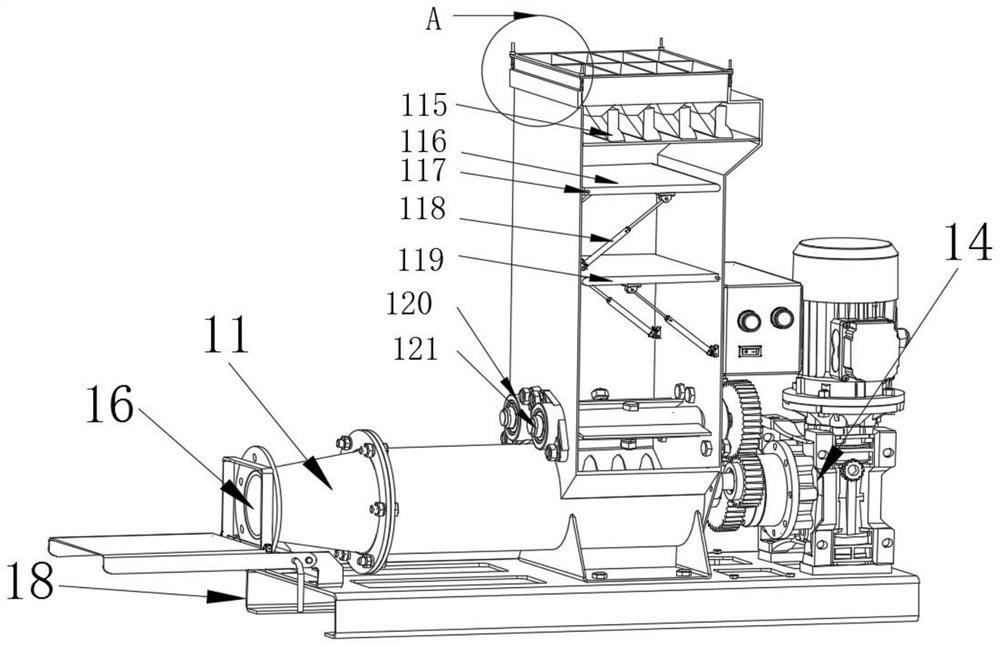

[0035] see Figure 1-8 , a kind of cloud flow pattern plastic product processing technology with ABS as base material, comprises the following steps:

[0036] S1, material retrieving: according to the weight of the material, take 70 parts of ABS plastic pellets, 12 parts of mica, 12 parts of heat-resistant agent, 10 parts of co-solvent, 6 parts of wear-resistant agent and 5 parts of antioxidant;

[0037] S2. Material preparation: Add the mixture of ABS plastic pellets, mica, heat-resistant agent, co-solvent, co-solvent, wear-resistant agent and antioxidant prepared in step S1 to the quantitative filling end of the processing equipment In the cover plate 13, the quantitative filling is carried out according to the filling funnel 133 in the quantitative filling end cover plate 13, and enters the inside of the upper feeding end 12 from the feed baffle assembly 115, and first pushes the material with the first constant speed. The baffle plate 116 is in contact, and the first unif...

Embodiment 2

[0046] In this example, "the parts by weight of the material are 70 parts of ABS plastic pellets, 12 parts of mica, 12 parts of heat-resistant agent, 10 parts of cosolvent, 6 parts of anti-wear agent and 5 parts of antioxidant" in Example 1 "The number of materials is 55 parts of ABS plastic pellets, 10 parts of mica, 10 parts of heat-resistant agent, 5 parts of co-solvent, 3 parts of wear-resistant agent and 2 parts of antioxidant", and other descriptions are guaranteed to be consistent.

Embodiment 3

[0048] In this example, "the parts by weight of the material are 70 parts of ABS plastic pellets, 12 parts of mica, 12 parts of heat-resistant agent, 10 parts of cosolvent, 6 parts of anti-wear agent and 5 parts of antioxidant" in Example 1 "The number of material parts is 60 parts of ABS plastic pellets, 11 parts of mica, 11 parts of heat-resistant agent, 7 parts of co-solvent, 4 parts of wear-resistant agent and 3 parts of antioxidant", and other descriptions are guaranteed to be consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com