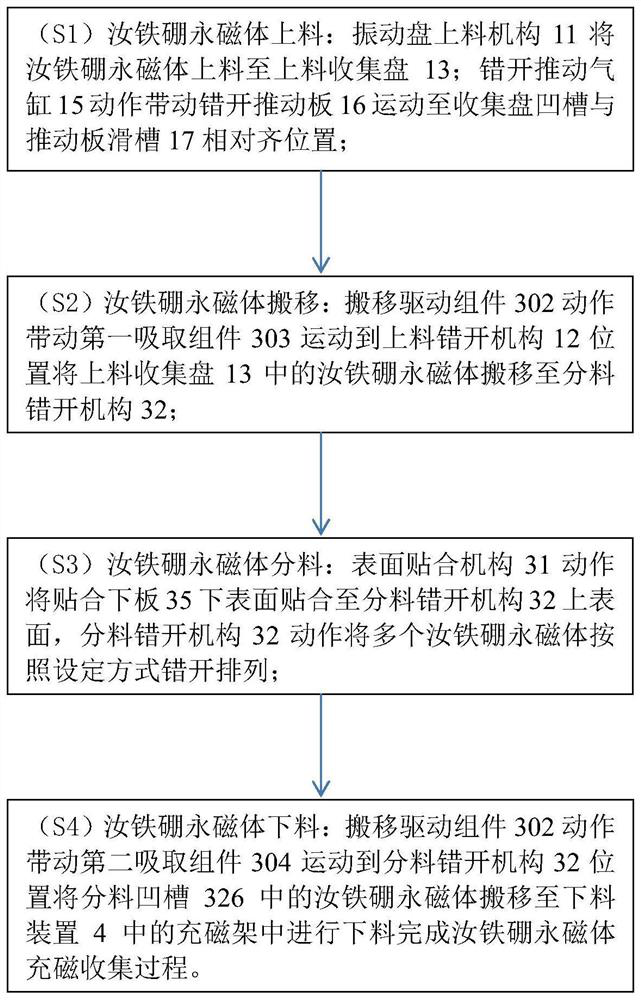

Neodymium-iron-boron permanent magnet magnetizing collecting method and device

A technology of collecting equipment and permanent magnets, which is applied in transportation and packaging, conveyor objects, conveyors, etc., can solve problems such as spending a lot of time, affecting the accuracy of feeding actions, and unfavorable automatic processing of equipment, and achieves high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

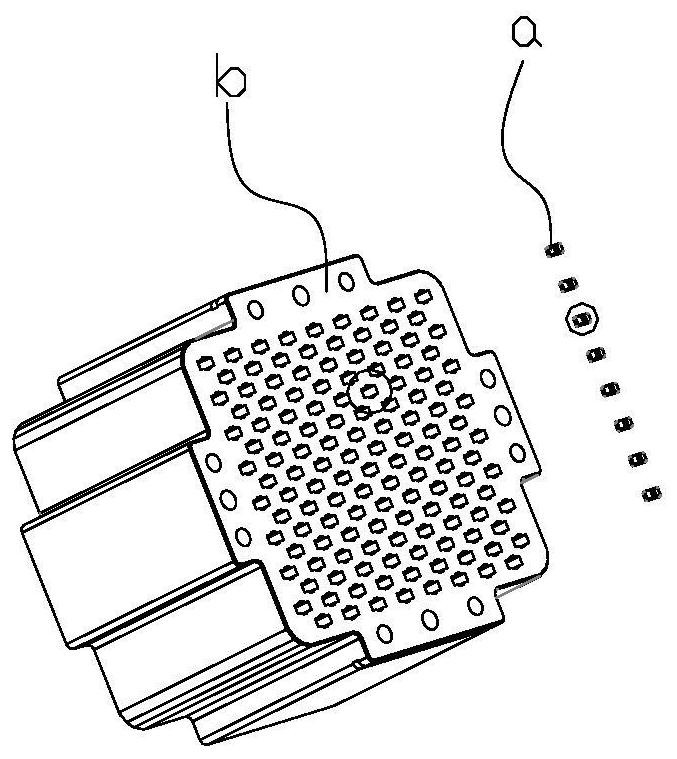

[0048] Such as Figure 1-18 A kind of NdFeB permanent magnet magnetization collecting equipment shown, this equipment comprises workbench and the feeding device 1 that is fixed on the workbench, the distributing and moving device 3 and the unloading device 4; The distributing and moving device 3 and The feeding device 1 and the unloading device 4 are connected; the feeding device 1 is used for feeding the NdFeB permanent magnets; the material distribution and moving device 3 is used for distributing the NdFeB permanent magnets according to the set arrangement and distributing the NdFeB permanent magnets. The iron-boron permanent magnets are moved to each station; the unloading device 4 is used to collect the NdFeB permanent magnets into the magnetizing frame.

[0049] The product flow direction of NdFeB permanent magnets is: feeding device 1 to material distributing and moving device 3 to unloading device 4.

[0050] Such as figure 2 , 3 , 4 shows the structure diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com