Dredger sand blowing and sea filling pipeline structure

A technology of dredgers and blow-fill pipes, which is applied in the direction of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., which can solve the problem of low efficiency and range of sediment transportation and reduce land reclamation Improve operating efficiency, facilitate inspection and maintenance, and reduce equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

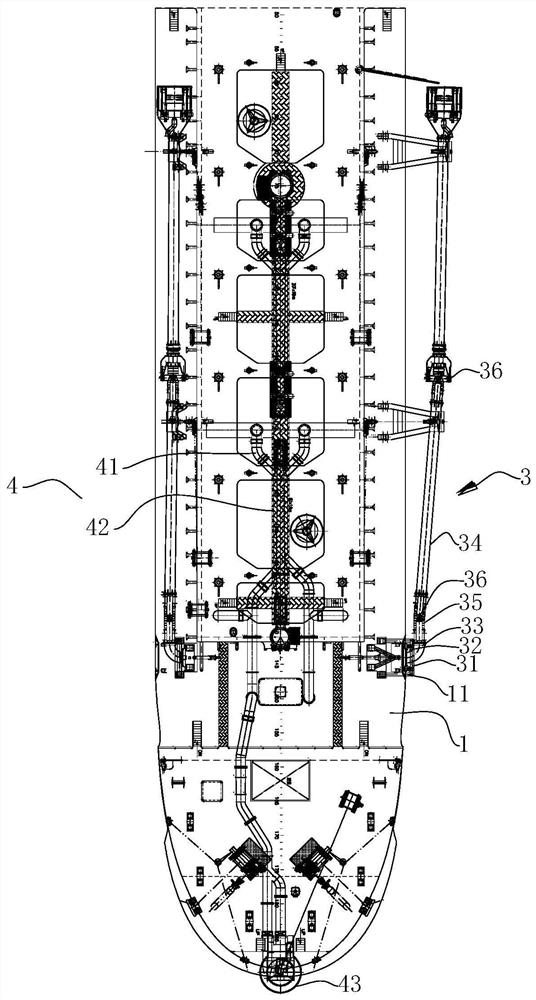

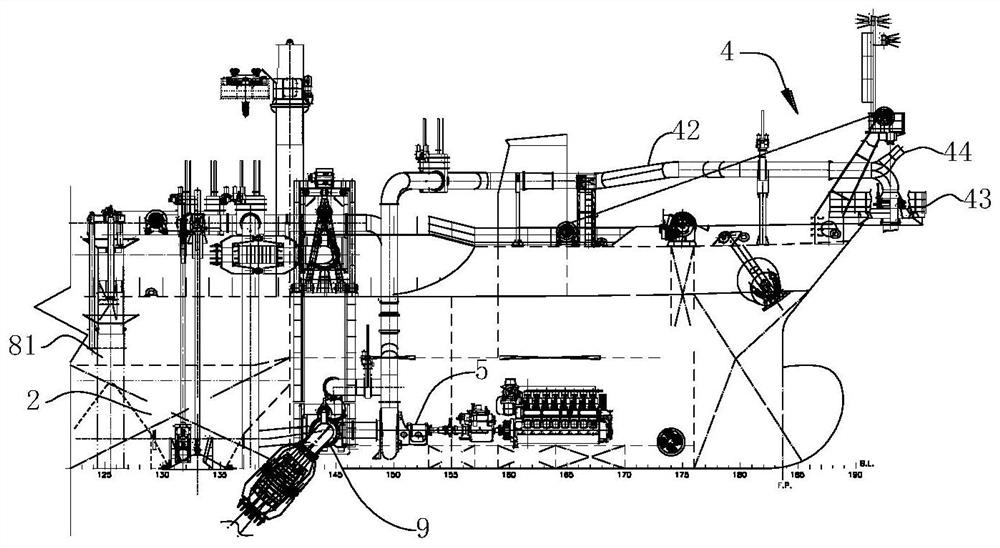

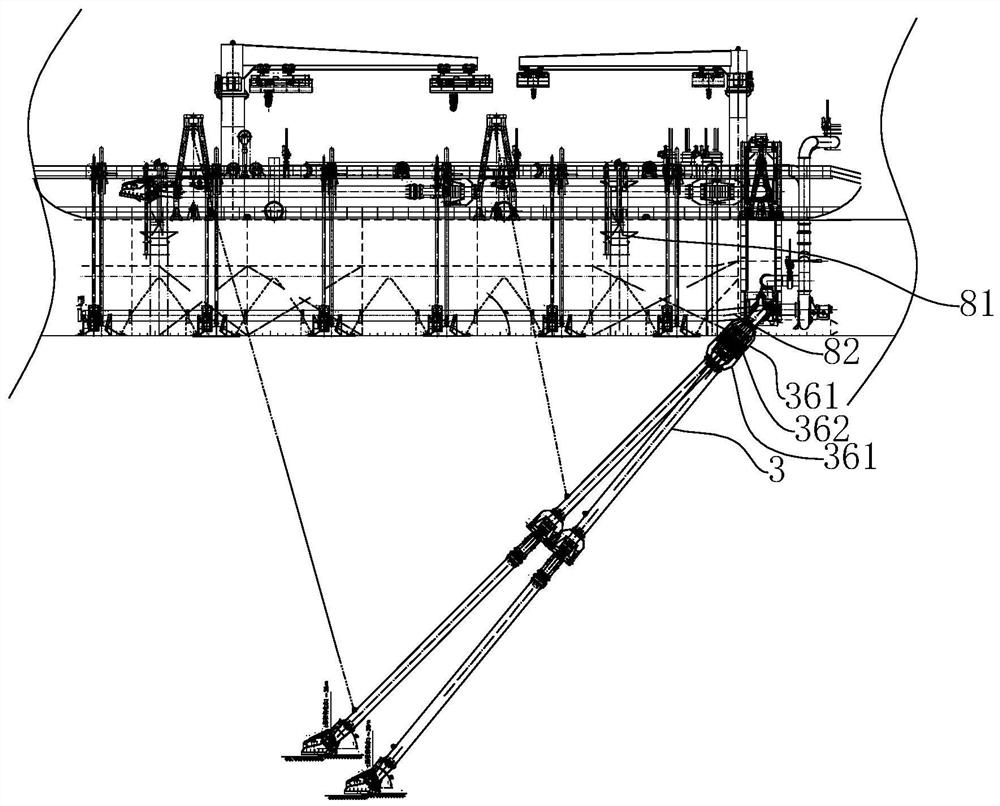

[0026] A pipeline structure for sand blowing and sea reclamation by dredgers, refer to figure 1 As shown, it includes a hull 1 , a mud tank 2 located at the bottom of the hull 1 , a suction pipeline mechanism 3 , a drainage pipeline structure 8 , and a filling pipeline structure 4 . The suction pipeline mechanism 3 is connected to the hull 1 and communicates with the mud tank 2, and a power device 5 is arranged in the mud tank 2. This power unit 5 is a mud pump.

[0027] refer to figure 2 , one side of the hull 1 is provided with a connection port 9 for detachably connecting the rake suction pipeline mechanism 3 . The connection port 9 is used for the common use of mud and sand water in and out. During the raking operation, the raking suction pipeline mechanism 3 is assembled to the connection port 9, and the power device 5 forms a negative pressure power at the connection port 9, so that the mud and water are drawn away and enter the output pipe of the power device 5 roa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com