Movable processing shed and manufacturing method thereof

A processing shed and mobile technology, applied in the field of mobile processing shed and its production, can solve the problems affecting the project construction efficiency, the impact of construction efficiency, and the increase of construction cost, so as to facilitate storage and transportation, improve air permeability, reduce Harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

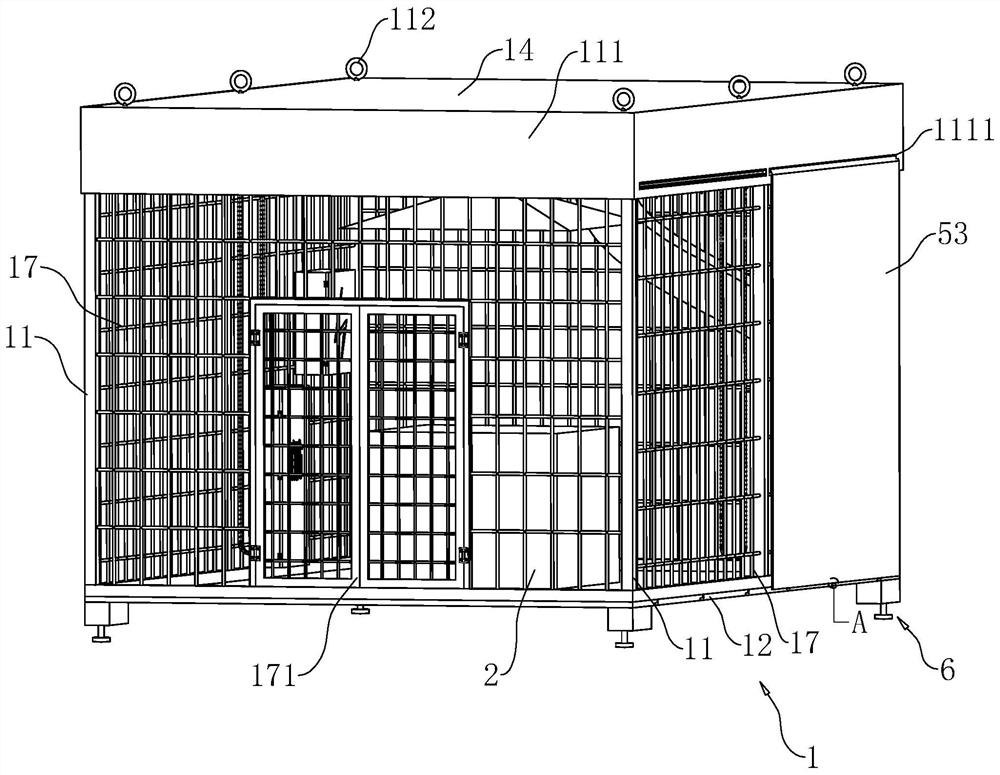

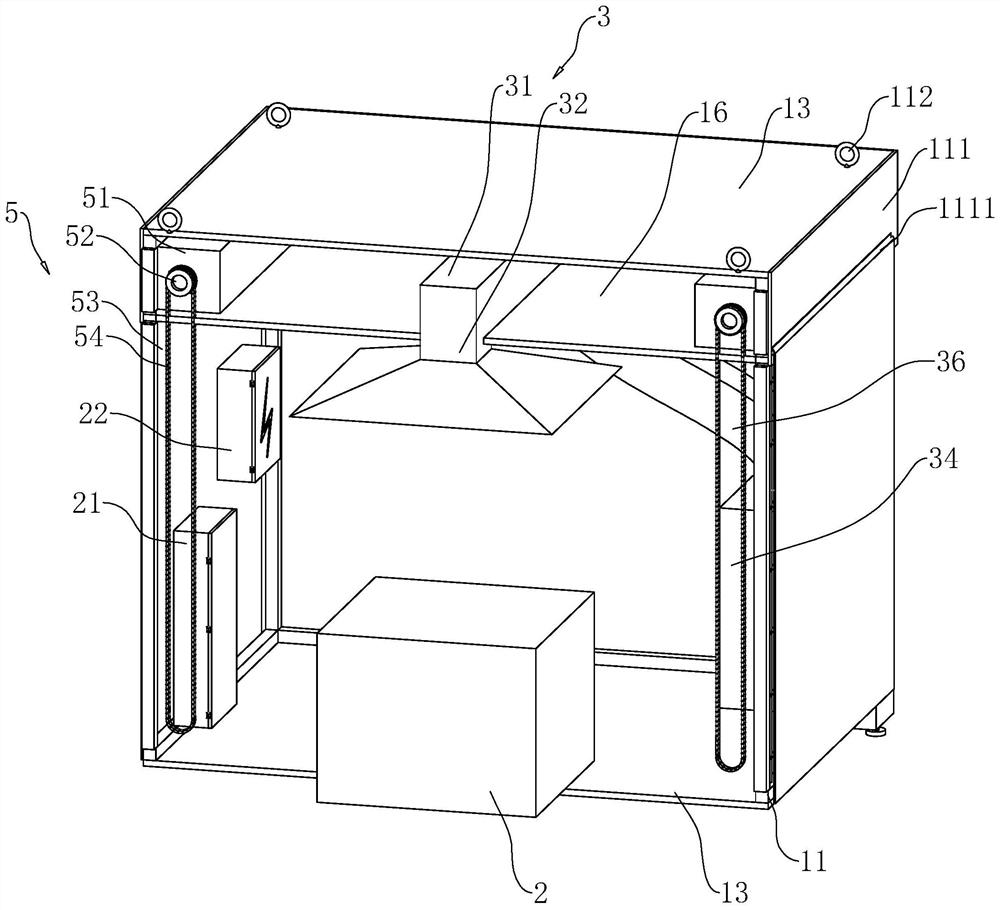

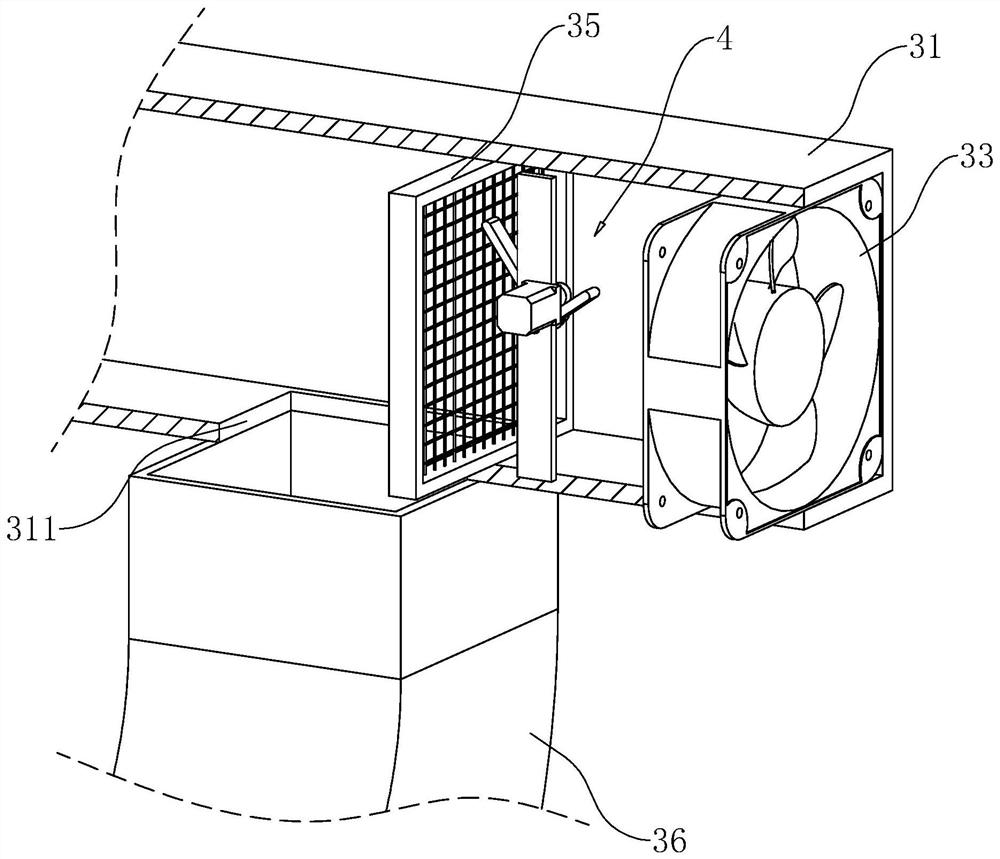

[0052] The embodiment of the application discloses a mobile processing shed. refer to figure 1 and figure 2 , the mobile processing shed includes a steel structure frame 1, an operating platform 2 arranged in the steel structure frame 1; the steel structure frame 1 includes a column 11, a cross bar 12 and a bottom plate 13; there are multiple columns 11, and the multiple columns 11 are vertical There are many cross bars 12, and the cross bars 12 are arranged horizontally respectively. structure; the bottom plate 13 is fixed on the lower crossbar 12; the upper crossbar 12 is fixedly connected with the top plate 14; the vertical rods are horizontally fixed with lap rods 15, and there are many lap rods 15 and many lap rods. The connecting rod 15 is arranged horizontally, and a plurality of connecting rods 15 form a frame structure. The ring is fixedly connected with an iron sheet 111, and the iron sheet 111 is arranged around a plurality of columns 11. The upper and lower sid...

Embodiment 2

[0076] The embodiment of the application discloses a mobile processing shed. The processing shed in this embodiment differs from the processing shed in Embodiment 1 in that the steel structure frame 1 is different.

[0077] refer to Figure 8 and Figure 9 , the steel structure frame 1 includes a support frame 18 and a cross bar 12. There are four support frames 18, and every two support frames 18 form a group, and the support frames 18 on both sides are arranged oppositely. The hinge shaft is located on the side of the two support frames 18 towards the outside of the processing shed; and between the upper and lower corresponding support frames 18, a positioning piece 7 for fixing the two support frames 18 is arranged; A top plate 14 is connected, and a bottom plate 13 is fixed between the cross bars 12 on the lower side; protective nets 17 are fixedly connected to the outer surfaces of the support frame 18 respectively.

[0078] refer to Figure 8 and Figure 9 , the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com