Construction method of cast-in-place cantilever bay window plate

A construction method and overhanging technology, which is applied in the field of concrete slab pouring, can solve the problems of inconvenient construction methods for bay window slabs, achieve safe and reliable project quality, reduce project costs, and save secondary structure construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

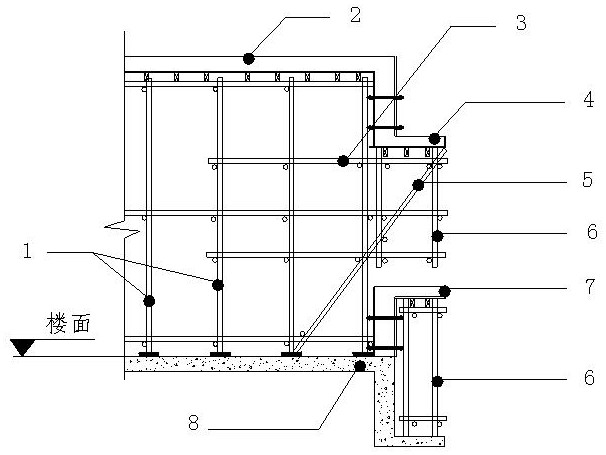

[0028] The construction method of the cast-in-place cantilevered bay window panel of the present invention comprises the following steps:

[0029] (1) Measuring and setting out

[0030] According to the requirements of the design drawings, the plane position line and elevation control line where the window sill is located will pop up.

[0031] (2) Concrete chisel

[0032] Since the formwork is installed on the poured floor of the lower window sill, it is the handover of old and new concrete, so the floor where the lower window sill is located should be chiseled first, and the surface layer of cement exposed stones should be chiseled, and rinsed with clean water.

[0033] (3) Set up formwork support system

[0034] see now figure 1 , figure 1 It is a schematic structural diagram of the formwork support system of the cantilevered bay window slab according to the embodiment of the present invention, the floor slab 2 to be poured, the bay window sill 7 lowered, and the floor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com