Intelligent energy-saving method and device for drilling fluid wireless drilling instrument

A wireless while drilling and energy-saving device technology, applied in the field of control, can solve the problems of long ineffective power supply time of downhole instruments, affecting the work of mud pumps, and limited power-on life of downhole instruments, so as to reduce ineffective power-on time and ineffective working time , Increase the effect of effective working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

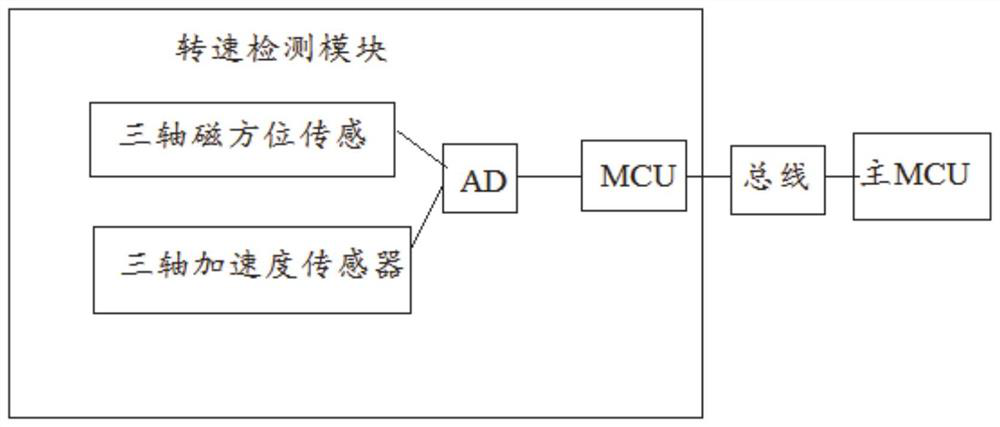

[0025] See attached figure 1 As shown, this embodiment discloses an intelligent energy-saving device for a drilling fluid wireless MWD, including a rotational speed detection module, and the rotational speed detection module is installed inside the drilling fluid wireless MWD for detecting Drill pipe speed, including three-axis magnetic azimuth sensor, three-axis acceleration sensor, MCU, MCU establishes communication with the main MCU in wireless MWD through 485 or CAN bus; among them, the speed sensor measures magnetic azimuth and gravity acceleration , can calculate the magnetic force and gravity tool surface, and then calculate the rotation speed, magnetic azimuth and gravity acceleration according to the magnetic force and gravity tool surface, and can directly measure internally without any relationship with the outside.

[0026] The rotational speed detection module transmits the detected drill pipe rotational speed of the drilling fluid wireless MWD to the main MCU, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com