Resolution enhancement method for ultrasonic microscope

A resolution enhancement, ultrasonic microscope technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and analysis of materials, etc., can solve the problem of difficulty in improving imaging resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

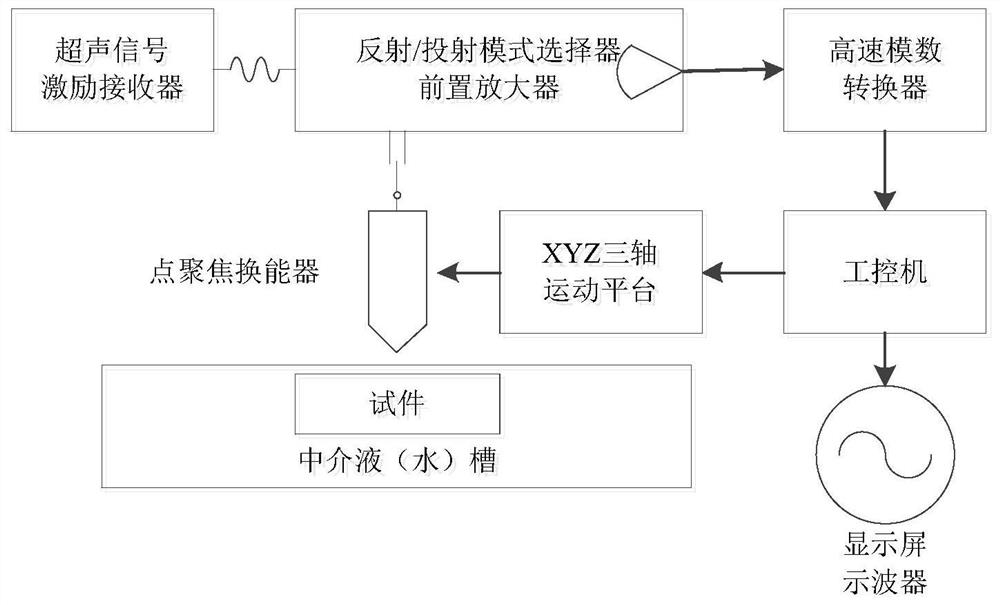

[0039] This embodiment discloses a method for enhancing the resolution of an ultrasonic microscope, the method is:

[0040] Step 1, setting parameters to obtain the ultrasonic tomographic scanning results of the test piece;

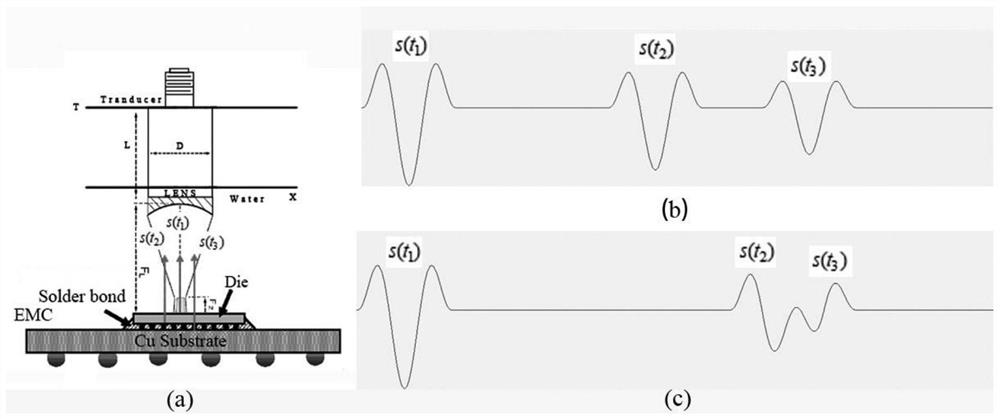

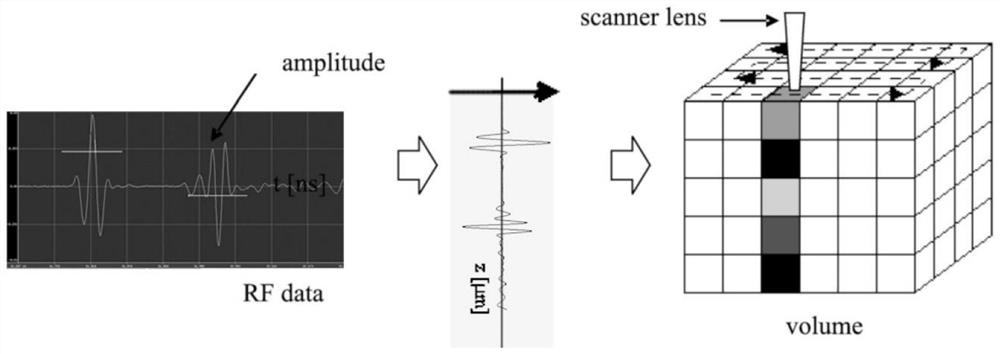

[0041] Step 2, adopt discrete wavelet decomposition to carry out multi-scale analysis to the ultrasonic signal of each point, generate low-frequency component and high-frequency component;

[0042] Step 3, use the Wiener deconvolution filter to process the low frequency components, and separate the superimposed signals;

[0043] Step 4, performing discrete wavelet inverse transform on the separated signal and high-frequency component, and reconstructing the ultrasonic tomographic scanning data;

[0044] Step 5. Using the reconstructed ultrasound tomography data to generate higher resolution vertical and horizontal profile images.

[0045] In step 1, set the parameters to obtain the ultrasonic tomographic scanning data of the specimen, and its data struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com