Mechanical part machining precision detection guide system based on augmented reality

A technology of processing precision and guidance system, which is applied in computer parts, mechanical mode conversion, semi-structured data retrieval, etc., can solve problems such as dependence on workers, high environmental requirements, and increased land occupation cost of cameras, and achieve high detection accuracy, The effect of strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The directional terms mentioned in the present invention, such as "up", "down", "front", "back", "left", "right", "inside", "outside", "side", etc., are only appended The directions in the figure are only used to explain and illustrate the present invention, not to limit the protection scope of the present invention.

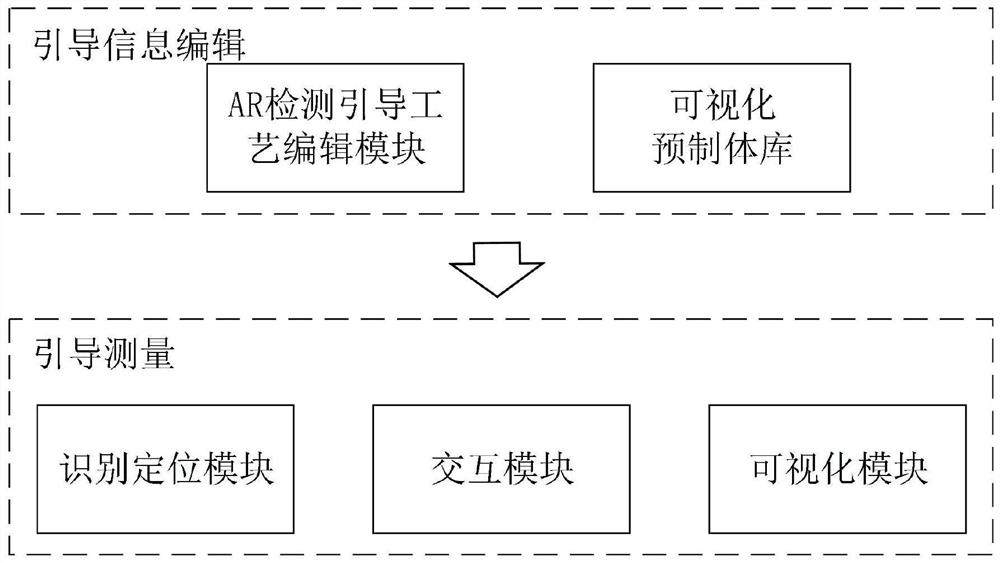

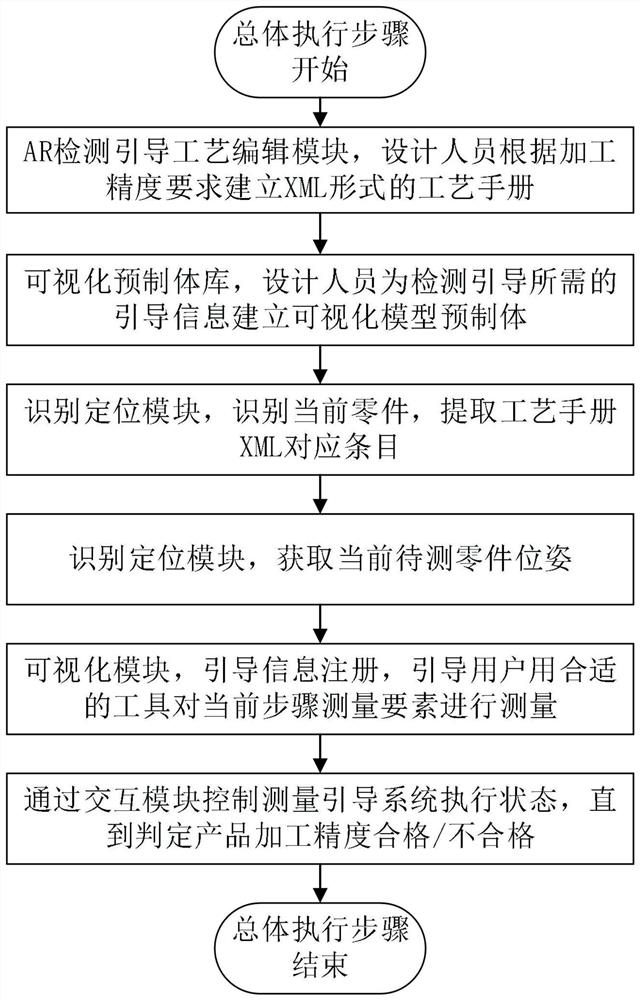

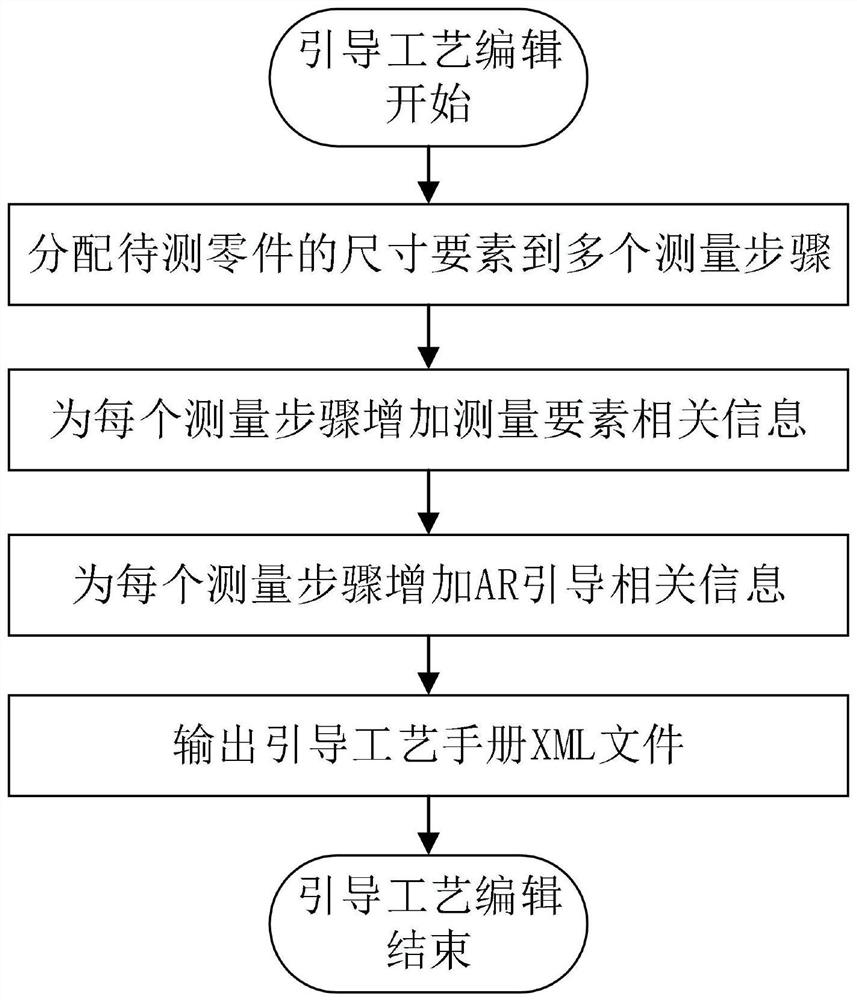

[0026] The purpose of the present invention is to solve the problem that workers need to frequently check paper or electronic process manuals during the current mechanical parts inspection, resulting in low efficiency and prone to missed and wrong inspections, and proposes a mechanical parts based on augmented reality. Detection and guidance system, the system includes guidance information editing and guidance measurement; guidance information editing includes AR detection guidance process editing module and visualized prefabricated body library, guidance measurement includes identification positioning module, interaction module and visualization module; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com