Welding image defect identification method and device, storage medium and equipment

A defect identification and welding defect technology, applied in the field of welding image defect identification, can solve the problems of long training time, large manpower and material resources, and achieve the effect of long training time, efficient training and improving the probability of being trained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

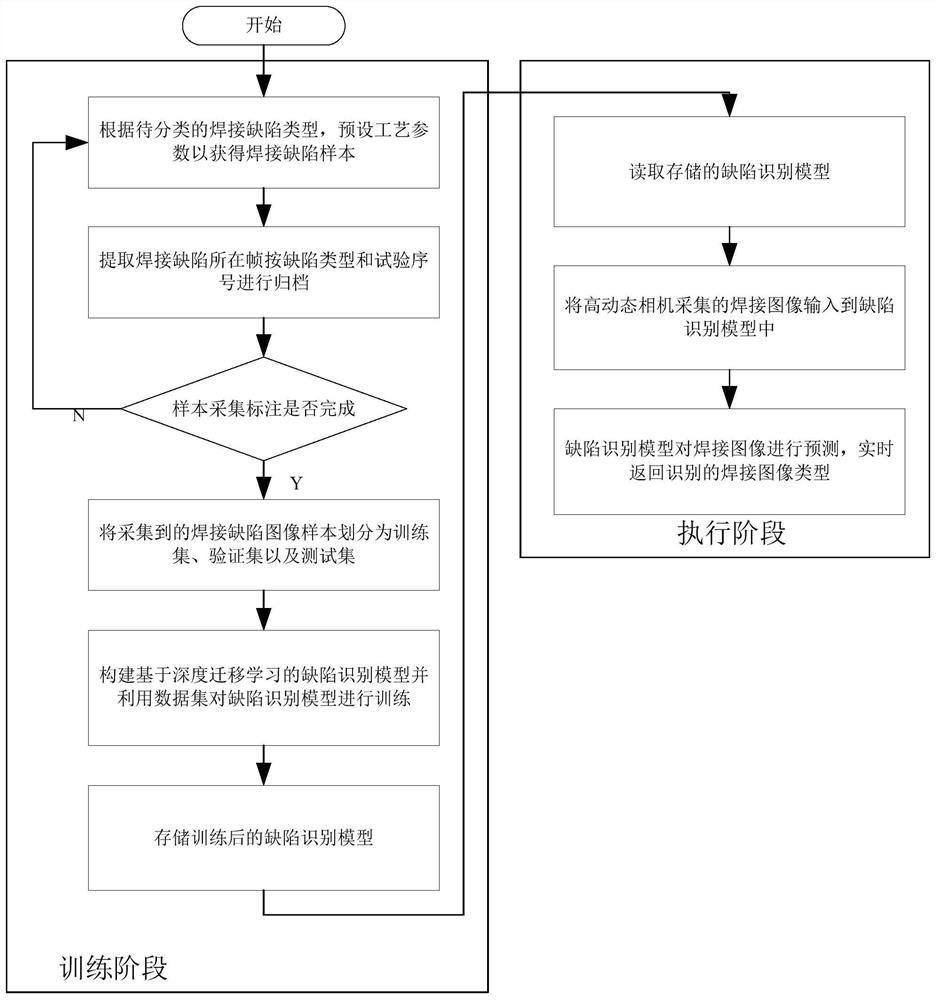

[0058] In this embodiment, a welding image defect recognition method, the process is as follows figure 1 shown, including:

[0059] Obtain the welding image to be identified;

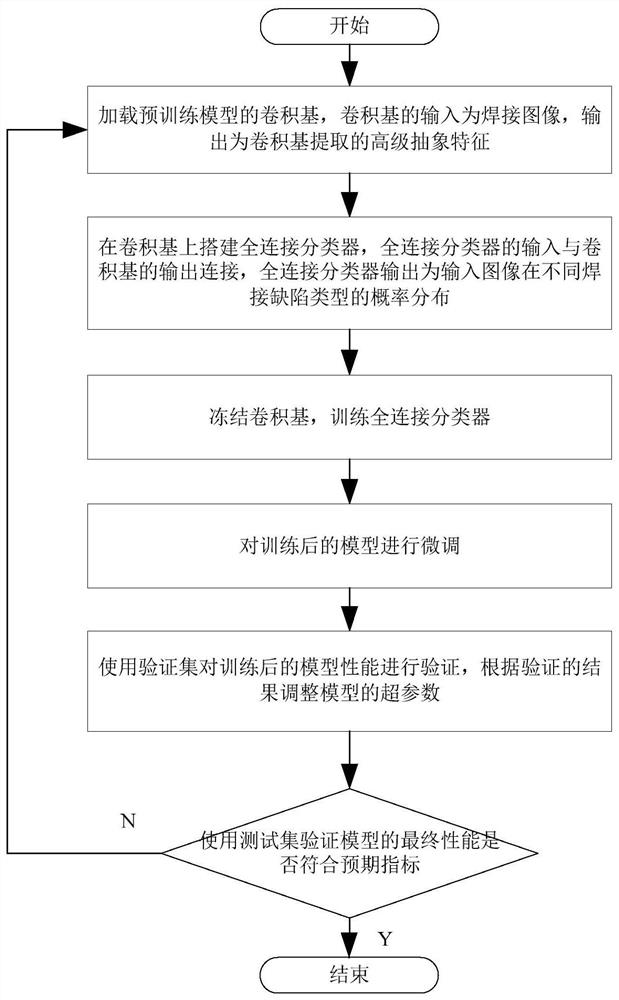

[0060] Inputting the welding image to be identified into the defect recognition model, identifying the welding image through the defect recognition model, and obtaining the type of welding image, thereby determining whether there is a defect in the welding image and determining the type of welding defect if there is a defect; wherein, The defect recognition model described above is a model obtained by training the initial defect recognition model.

[0061] The training process of the initial defect recognition model refers to the following steps:

[0062] S101. Collect welding image samples of all types of welding defects. Including the following sub-steps:

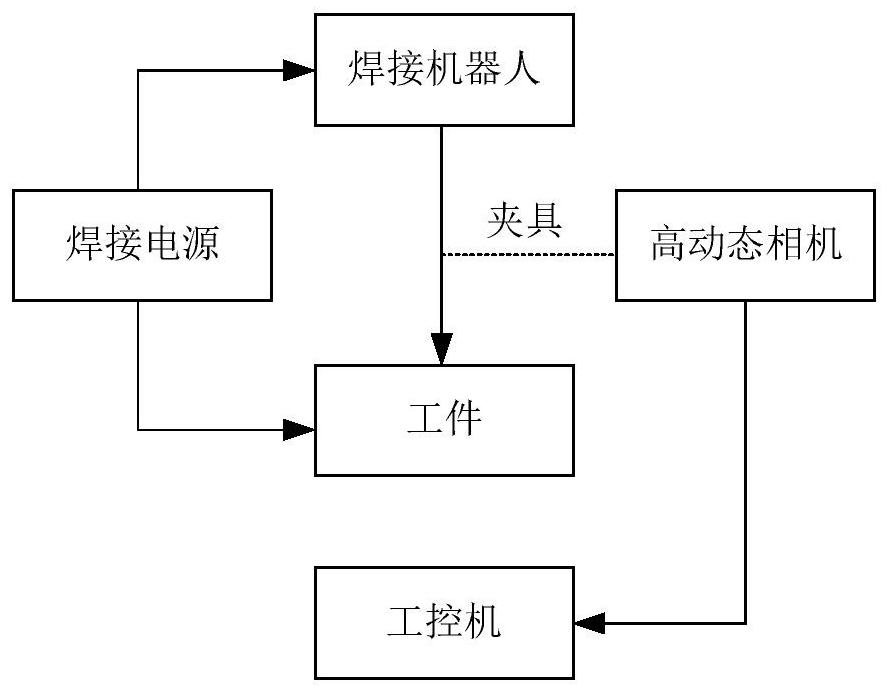

[0063] S1011. According to the types of welding defects to be classified, preset the process parameters of the welding robot and welding power...

Embodiment 2

[0097] In order to realize the welding image defect recognition method described in Embodiment 1, this embodiment provides a welding image defect recognition device, including:

[0098] The data input module is used to obtain the welding image to be identified;

[0099] The data identification module is used to input the welding image to be identified into the defect identification model, identify the welding image through the defect identification model, obtain the type of welding image, and determine whether there is a defect in the welding image and the defect when there is a defect type; wherein, the defect recognition model is a model obtained by training the initial defect recognition model;

[0100] The training process of the initial defect recognition model refers to the following steps:

[0101] S101. Collect welding image samples of all types of welding defects;

[0102] S102. Divide the welding image samples into a training set, a verification set, and a test set...

Embodiment 3

[0106] A storage medium in this embodiment is characterized in that the storage medium stores a computer program, and when the computer program is executed by a processor, the processor executes the welding image defect recognition method described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com