A kind of pre-embedded full plug hole method of printed circuit board

A printed circuit board, plug hole technology, applied in the directions of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of blistering, tin beading, affecting the quality of circuit board plug holes, etc., to improve the blistering problem, improve Plug hole quality, the effect of eliminating air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

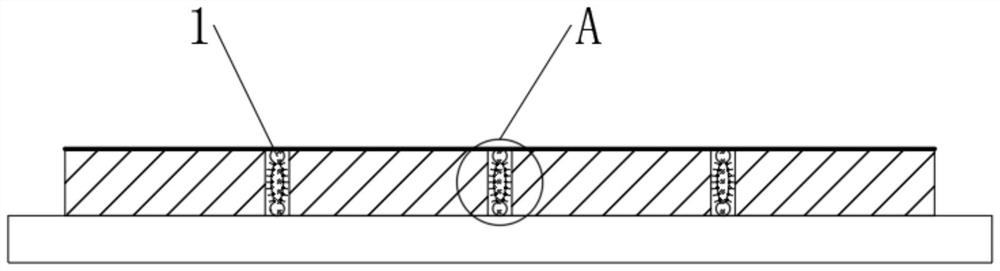

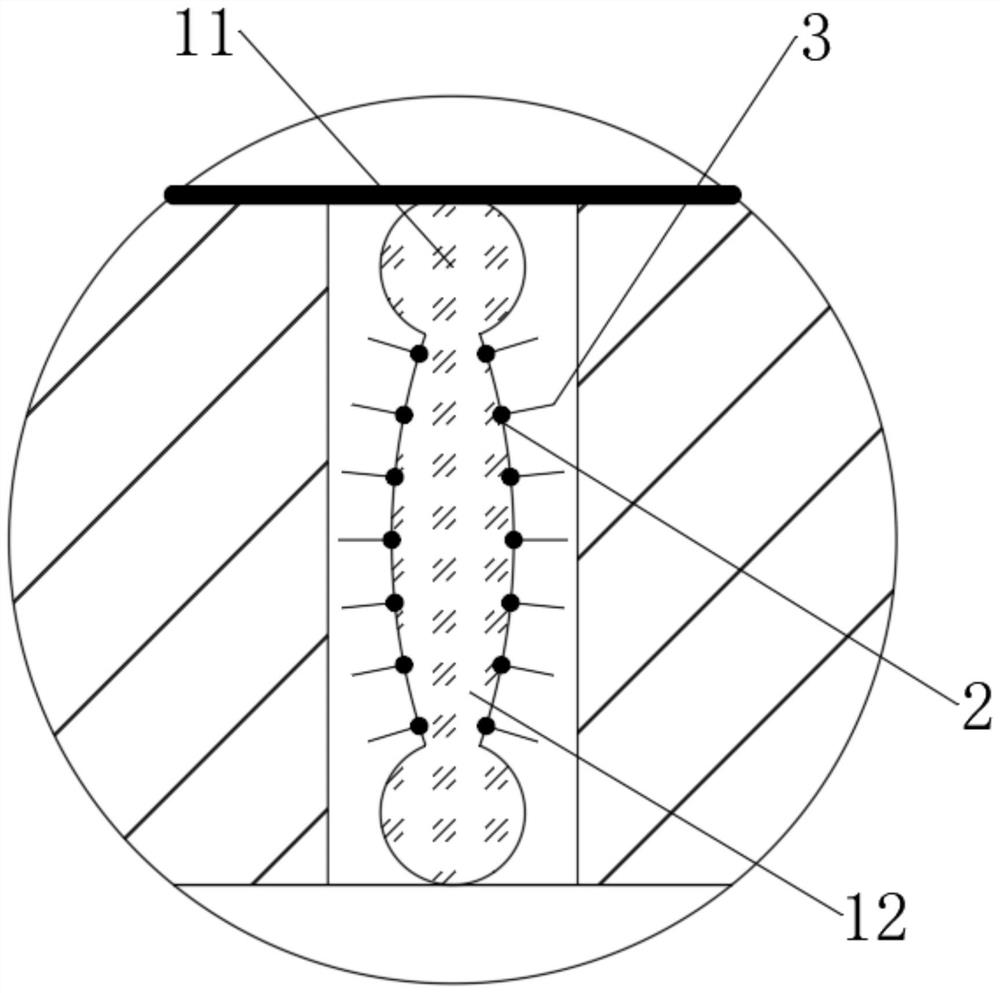

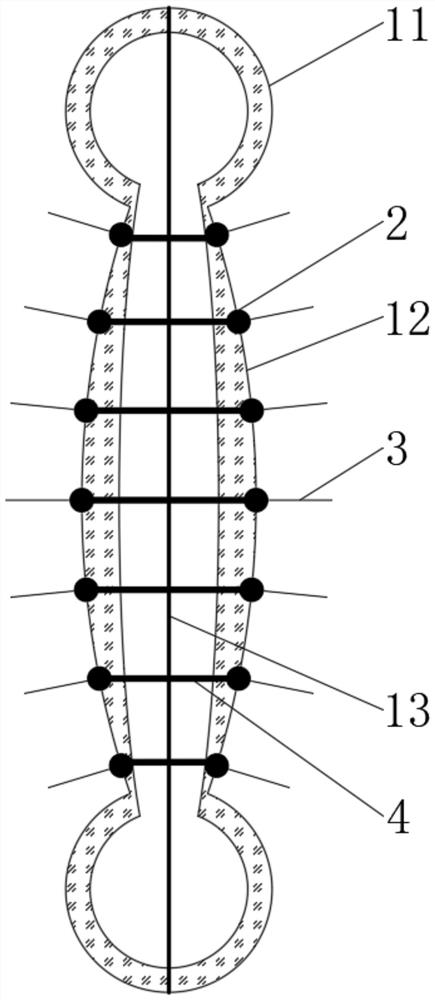

[0043] See figure 1 , A pre-buried full plunger method of a printed circuit board, a through hole having at least one standing hole is opened on a printed circuit board, including the following steps:

[0044] S1, the plug rod 1 is embedded into the through hole of the printed circuit board, and the vertical state is maintained after adjusting the position;

[0045] S2, the end surface of the printed circuit board is subjected to film treatment, covering the protective film;

[0046] S3, printed on the printed circuit board exposed to the protective film, and to ensure that the plug is fully covered with the through hole;

[0047] After the end of the plug, the printed circuit board is improved, and the plug rod 1 is blocked in the through hole, and the through hole is blocked, and the local micro-elimination air bubble is performed;

[0048] S5, the plug material is completely cured and removed from the protective film covered on the surface of the printed circuit board and peele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com