Preparation method and application of perovskite catalyst

A catalyst and perovskite technology, which is applied in the field of modification of titanium ore catalysts, can solve the problems of catalyst deactivation, low selectivity of low-carbon olefins, crushing and pulverization, etc., so as to inhibit the secondary hydrogenation reaction and improve the olefin Selectivity, reducing the effect of secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

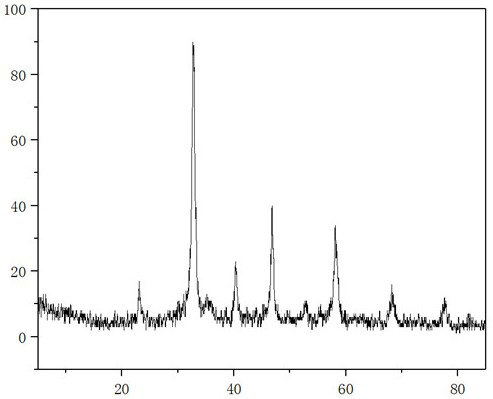

[0014] Weigh 6.5g of lanthanum nitrate, 10.1g of ferric nitrate, 6.25g of manganese nitrate, 19.2g of citric acid, dissolve in distilled water, stir and evaporate the solution in a water bath at 75°C until it becomes gelatinous, then put it in an oven at 105°C for 10 hours for further drying. To the heated dry powder was added 0.8 g of potassium ethoxide. Dry in an oven at 70°C for 10 h. Then grind the dry powder, put it in a muffle furnace, raise the temperature from room temperature to 450°C at a rate of 10°C / min and keep the temperature constant for 1h, then continue to heat up to 780°C at a rate of 5°C / min, keep it for 4h, take it out and cool it for collection , the catalyst samples were obtained after grinding. Denoted as sample 1. figure 1 It is the XRD pattern of sample 1, which shows that the perovskite type LaFeMnO was successfully prepared 3 .

Embodiment 2

[0016] Weigh 6.5g of lanthanum nitrate, 10.1g of ferric nitrate, 6.25g of manganese nitrate, 19.2g of citric acid, dissolve in distilled water, and add 1.6g of potassium ethoxide to the solution. Stir in a water bath at 75°C and evaporate to dryness until gelatinous, then place it in an oven at 105°C for 10 h for further drying. Grind the dry powder, place it in a muffle furnace, raise the temperature from room temperature to 450°C at a rate of 10°C / min and keep the temperature constant for 1 hour, then continue to heat up to 850°C at a rate of 5°C / min, keep it warm for 4 hours, take it out for cooling, collect, and grind Catalyst samples were then obtained. Denoted as sample 2.

Embodiment 3

[0018] Weigh 6.5g of lanthanum nitrate, 10.1g of ferric nitrate, 6.25g of manganese nitrate, 19.2g of citric acid, dissolve in distilled water, and add 1.2g of potassium tert-butoxide into the solution. Stir in a water bath at 80°C and evaporate to dryness until gelatinous, then place it in an oven at 105°C for 10 hours for further drying. Grind the dry powder, put it in a muffle furnace, raise the temperature from room temperature to 450°C at a rate of 10°C / min and keep the temperature constant for 1h, then continue to raise the temperature to 850°C at a rate of 5°C / min, keep it warm for 4h, take it out and cool it for collection, and grind Catalyst samples were then obtained. Denoted as sample 3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap