Feeding system of turnover type vibration mill

A technology of vibrating mill and feeding system, applied in solid separation, sieve, grid, etc., can solve the problems of increasing the burden of post-processing, no raw material crushing and screening, etc., to improve the filtering effect, improve the crushing effect, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

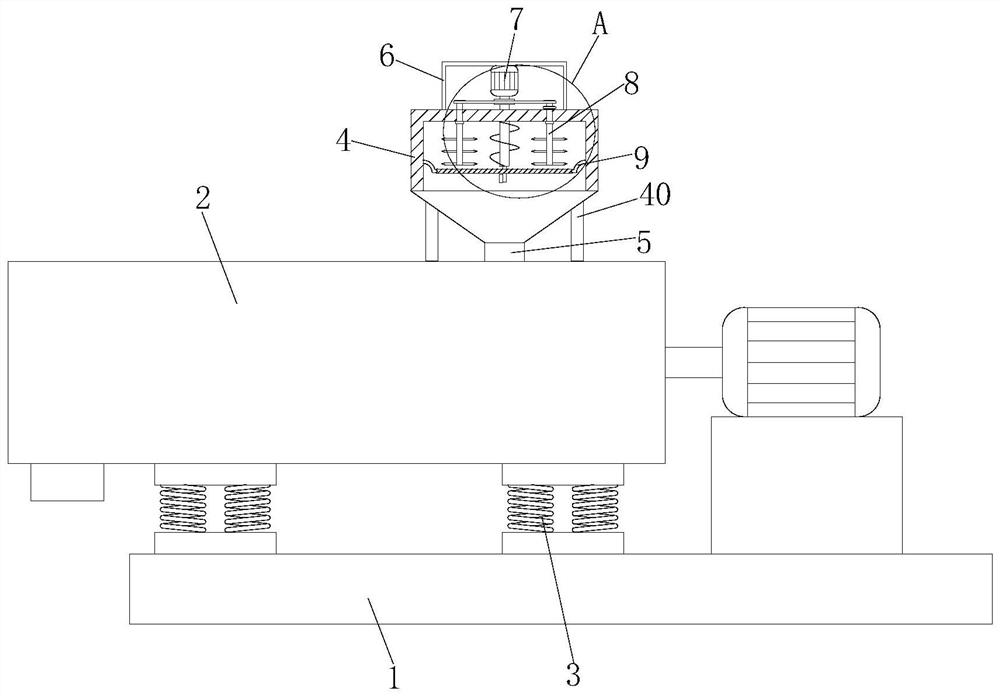

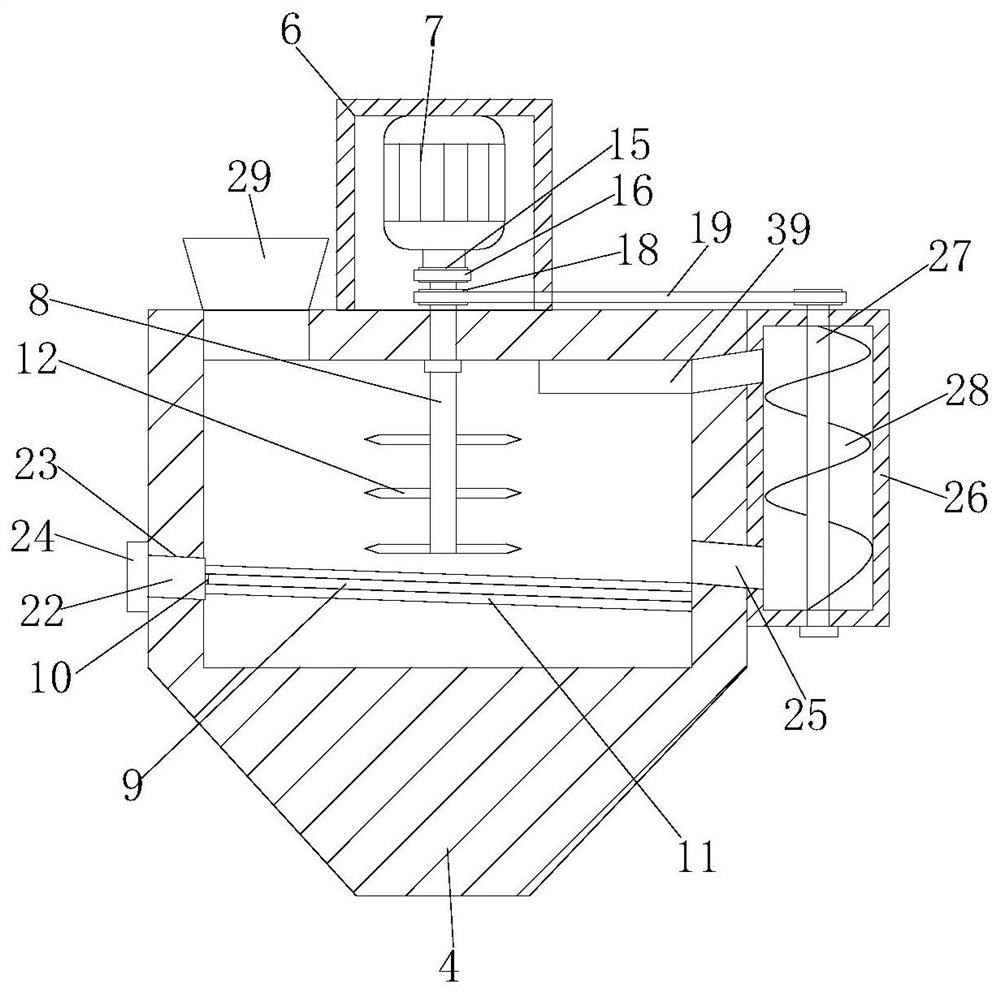

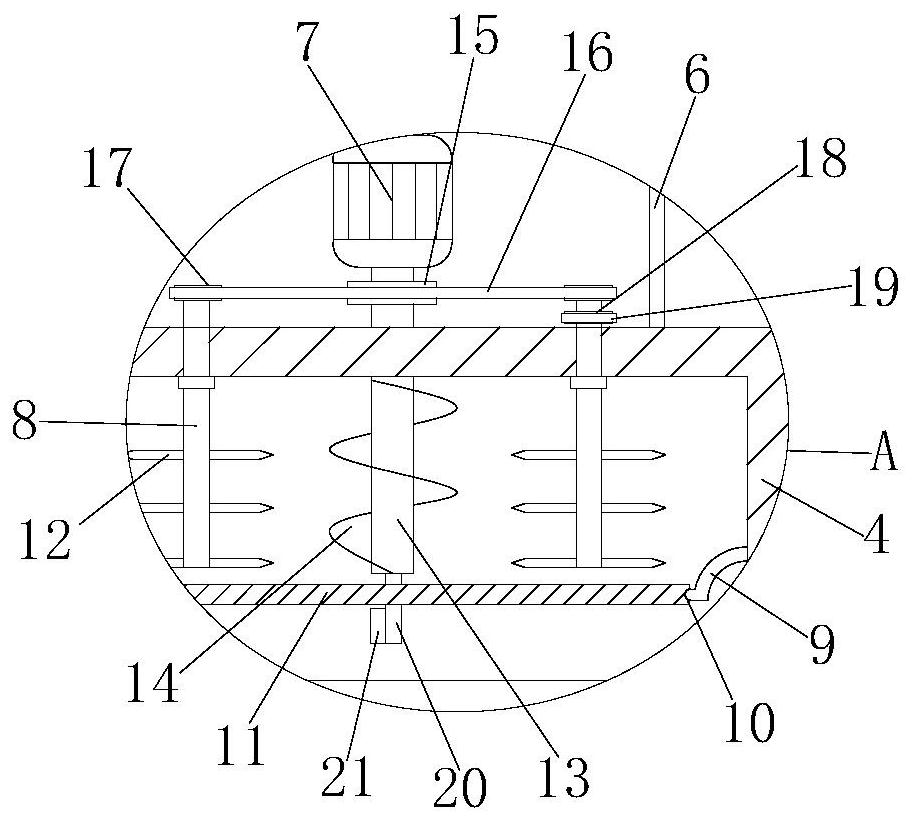

[0030] refer to Figure 1-5 , a feeding system for an overturning vibratory mill, comprising a chassis 1, a buffer structure 3 is arranged on the top of the chassis 1, an overturning vibrating mill 2 is arranged on the top of the buffering structure 3, and the top of the overturning vibrating mill 2 is fixedly connected There is an upper material cylinder 4, the same upper material tube 5 is connected between the bottom of the upper material cylinder 4 and the flipping vibratory mill 2, and two curved elastic rods 9 are fixedly installed on the inner walls of both sides of the upper material cylinder 4 The same filter plate 11 is slidingly connected between the two arc-shaped elastic rods 9, the filter plate 11 is arranged obliquely, the top of the upper material cylinder 4 is fixedly connected with the protective shell 6, and the top inner wall of the protective shell 6 is fixedly connected with the motor 7. A cylindrical rod 13 is fixedly installed on the output shaft of the...

Embodiment 2

[0041] refer to Figure 1-5 , a feeding system for an overturning vibratory mill, comprising a chassis 1, a buffer structure 3 is provided on the top of the chassis 1, an overturning vibrating mill 2 is arranged on the top of the buffering structure 3, and the top of the overturning vibrating mill 2 is passed through a screw The upper material cylinder 4 is fixedly connected, and the same upper material tube 5 is connected between the bottom of the upper material cylinder 4 and the flip-type vibratory mill 2, and two arcs are fixedly installed on the inner walls of both sides of the upper material cylinder 4 by welding. Shaped elastic rod 9, the same filter plate 11 is slidably connected between the two arc-shaped elastic rods 9, the filter plate 11 is arranged obliquely, the top of the upper barrel 4 is fixedly connected with the protective shell 6 by screws, and the top of the protective shell 6 The inner wall is fixedly connected with a motor 7 by screws, and a cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com