Automatic spraying machine

A technology of automatic spraying and racking, which is used in spray booths, spraying devices, liquid spraying devices, etc., can solve the problems of difficulty in all gas concentration, damage to the health of workers, and large environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

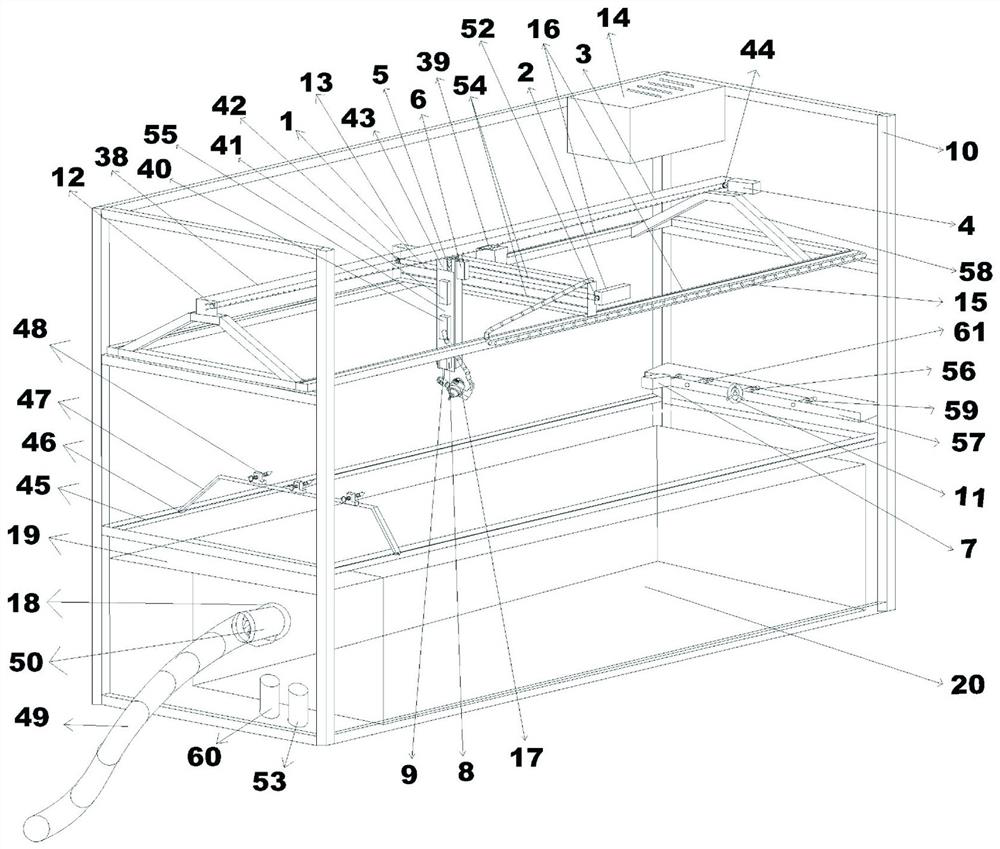

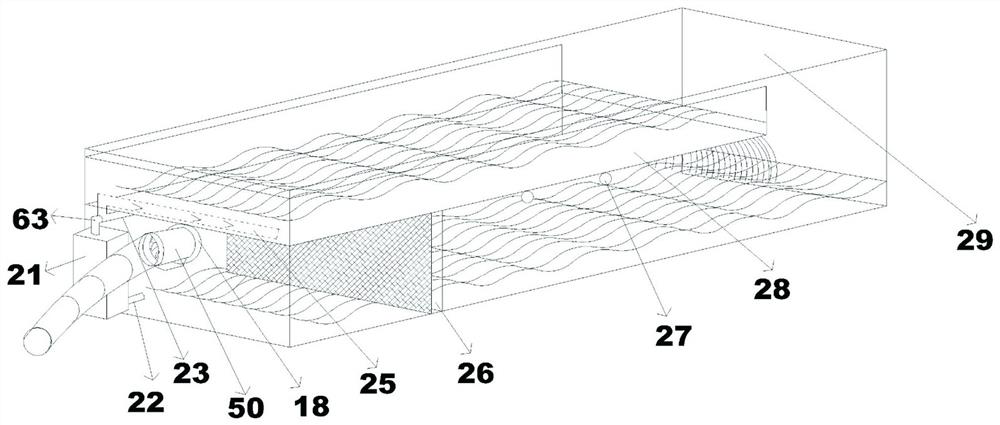

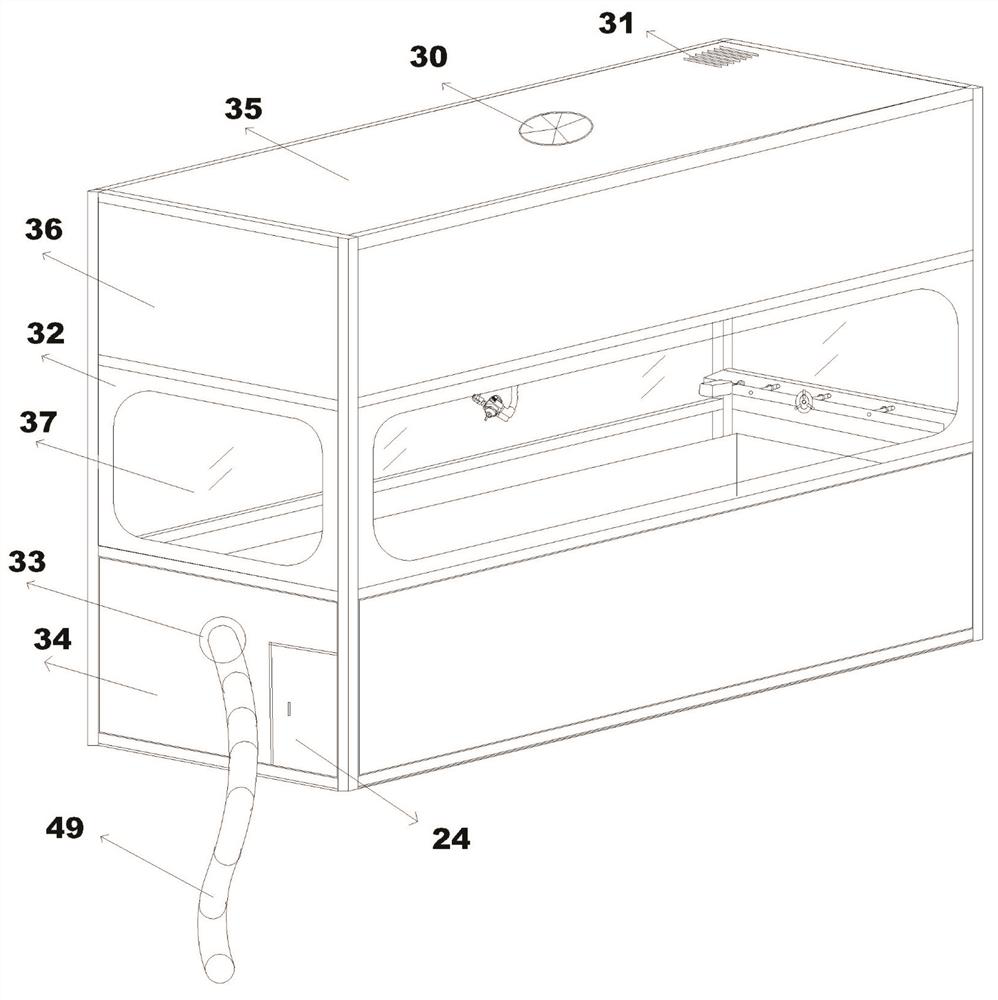

[0013] 1. The present invention is a closed digital device controlled by a computer, specifically an automatic spraying machine, such as Figure 1 to Figure 5As shown, first use the tailstock integration device 47 and workpiece fixture 11 to fix the workpiece, follow the three-dimensional shape of the workpiece to make a path with a computer, import the automatic spraying machine control software of the computer, generate numerical control data, and transmit it through the data line Control the digital control card inside the electric box 14 for the automatic spraying machine, and each driver is connected to the digital control card inside the control electric box with wires, and each driver in the control electric box transmits signal data to each stepper described respectively. motor. The motor shaft of the horizontal axis stepper motor 2 of the four-axis device 58 is sleeved with a synchronous pulley 52, and the horizontal axis stepper motor 2 is installed on the right end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com