Hot coil box dust suppression and removal device

A technology of dust removal device and hot coil box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

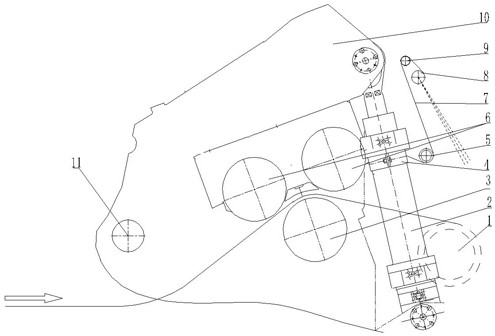

[0019] Such as figure 1 As shown, a hot coil box water mist dust suppression device includes a hot coil box frame, a bending roller assembly, a hydraulic system, an angle change system and a low-pressure water system.

[0020] The bending roller assembly includes a lower bending roller 3 and two upper bending rollers 6 . The two upper bending rollers 6 are installed on the frame 10, the lower bending roller 3 is fixed, and the two upper bending rollers 6 and the lower bending roller 3 form an arc-shaped roll gap; the blind end trunnion of the oil cylinder 2 is fixed, and the lug of the rod cavity The shaft is connected to the frame 10 through a pin shaft. The frame 10 moves within a certain range around the rotating shaft 11 under the thrust of the oil cylinder 2, and the body of the oil cylinder 2 will swing around the blind end trunnion.

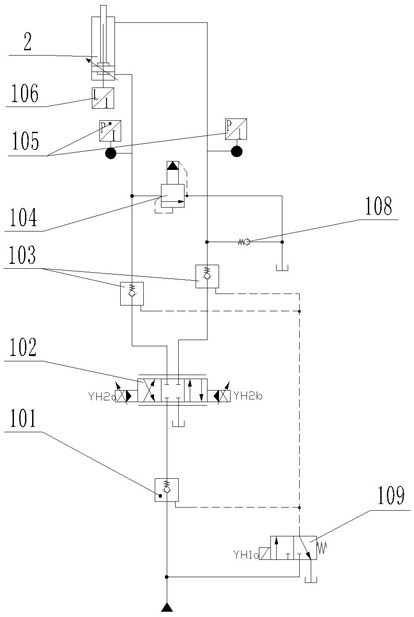

[0021] Such as figure 2 As shown, the hydraulic system includes sequentially connected hydraulic control check valves 101 and 103, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com