Innovative welding tool clamping device

A clamping device and welding tooling technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high parts production cost, high product repair cost, high scrap rate, and improve product qualification rate and production efficiency. , The effect of reducing the number of maintenance and repairs, and reducing the workload of rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

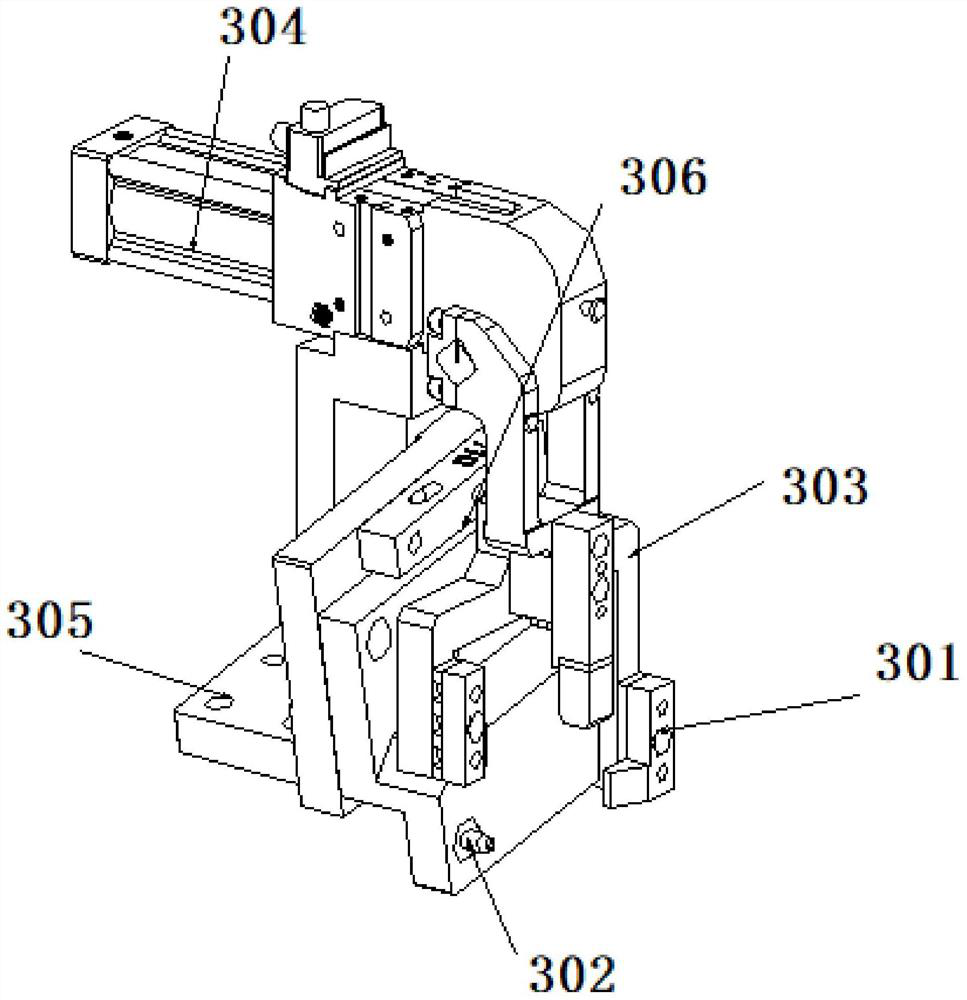

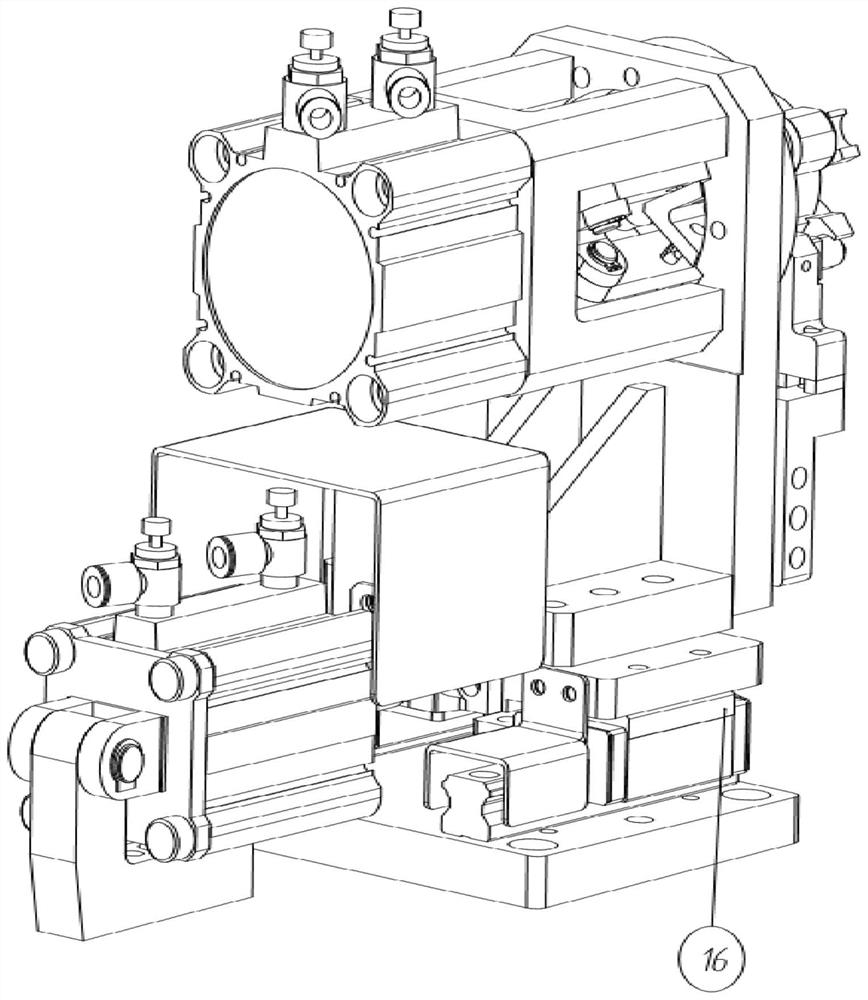

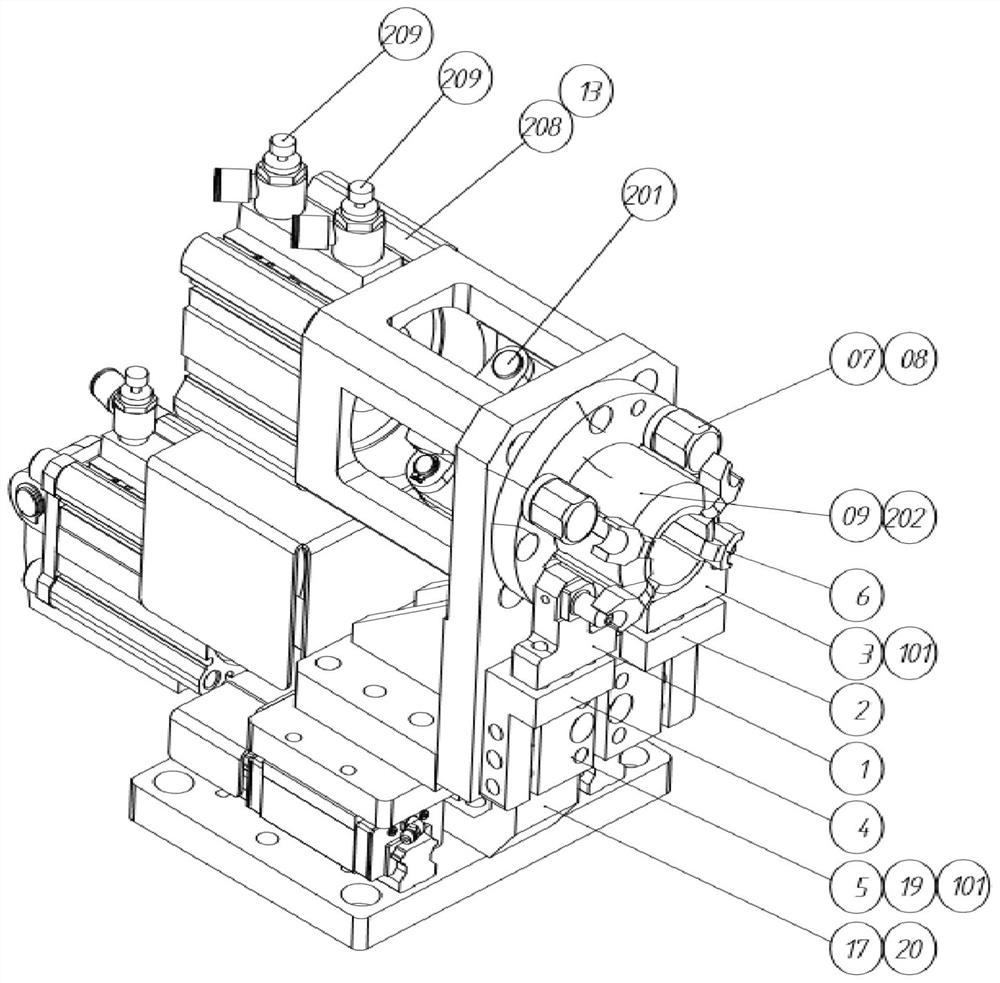

[0018] Embodiment: As shown in the accompanying drawings, this innovative welding tool clamping device mainly includes connecting block A1, connecting block B2, connecting block C3, connecting block D4, connecting block E5, pressing block 6, supporting block 7, and adjusting pads Sheet A8, connecting block F9, corner seat 10, connecting block G11, connecting block H12, connecting block I13, connecting block J14, connecting block K15, connecting block L17, connecting block M18, adjusting gasket B19, adjusting gasket C20, positioning Pin 24, adjusting gasket D101, hinge pin A201, hinge pin B202, cylinder A203, guide rail 207, cylinder B208, connect block M18 on the middle part of connection block K15, install guide rail 207 on both sides of connection block K15, and install on connection block M18 The cylinder A203 is provided with a regulating valve A204, and a protective cover B23 is installed outside the cylinder A203. The cylinder A203 is connected to the corner seat 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com