Novel supporting frame machining device and using method thereof

A processing device and support frame technology, applied in the field of mechanical processing, can solve problems such as insufficient smoothness, roughness, and affecting processing efficiency, and achieve the effects of improving smoothness and structural strength, reducing processing operations, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

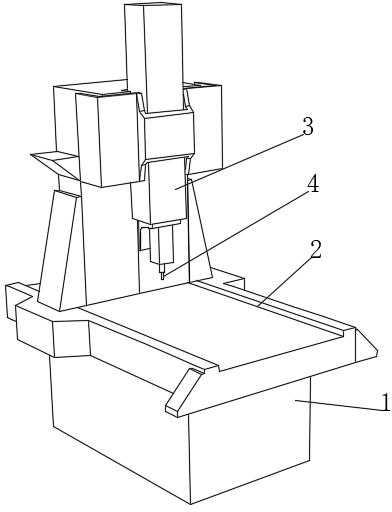

[0046] see figure 1 , a new type of support frame processing device, including a device body 1, a working platform 2 is fixedly installed on the upper end of the device body 1, a drilling assembly 3 is installed on the upper end of the working platform 2, and a segmented drill bit 4 is installed on the lower end of the drilling assembly 3.

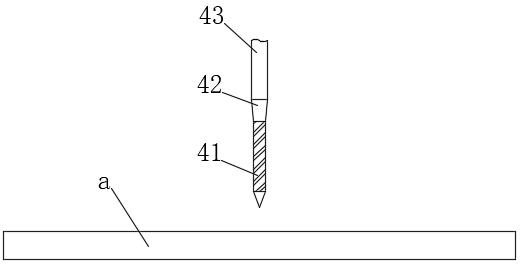

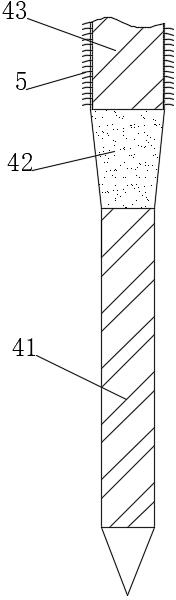

[0047] see Figure 2-3 , a in the figure represents the part of the support frame that needs to be drilled. The segment drill bit 4 includes a grinding rubber sealing section 43 connected to the drilling assembly 3, a reaming end 42 connected to the lower end of the grinding rubber sealing section 43, and a reaming end connected to the reaming rubber sealing section 43. The drilling end 41 at the lower end of the hole end 42, the part of the outer surface of the polishing rubber sealing section 43 located below the drilling assembly 3 is fixed with a plurality of evenly distributed paddle-type patches 5, and the reaming end 42 is a circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com