Rubber bushing edge grinding machine

A technology of rubber bushing and edging machine, applied in the field of rubber, can solve problems such as degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

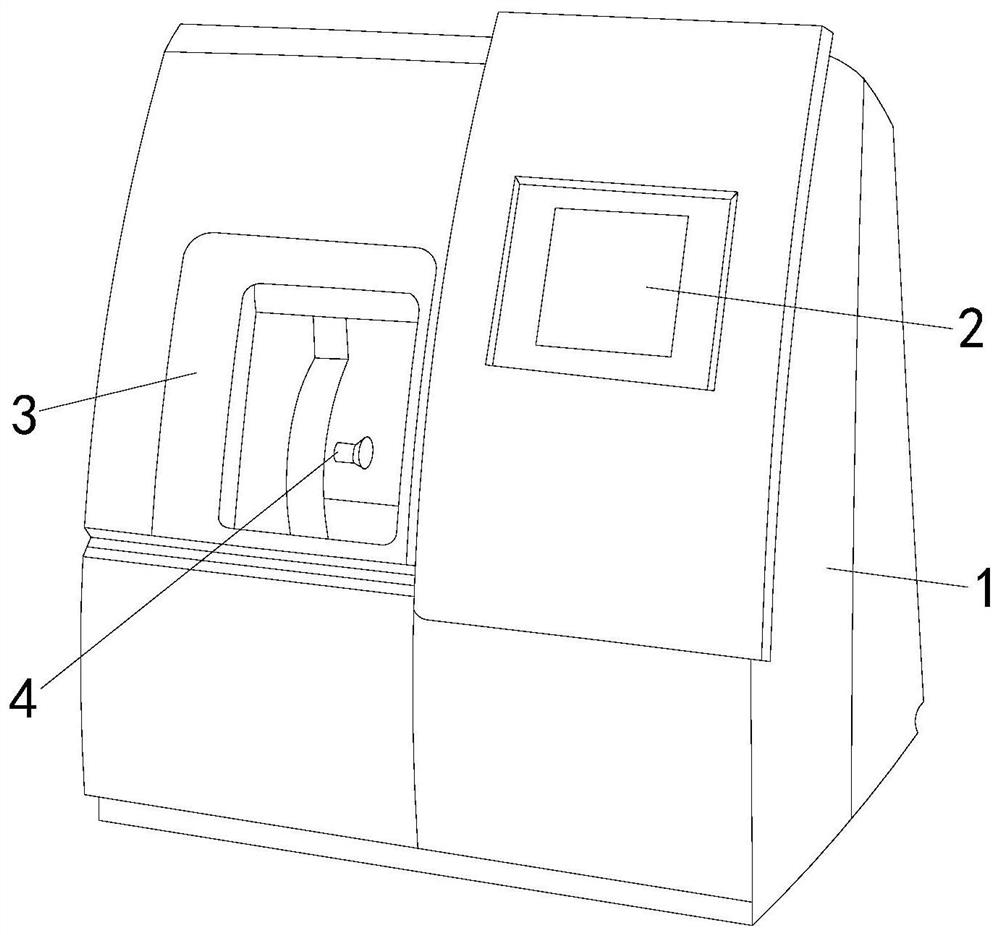

[0024] see figure 1 , the present invention provides a rubber bush edger, the structure of which includes: an edger frame 1, a control panel 2, an inspection window 3, and a grinding mechanism 4, and the side of the edger frame 1 is provided with a control panel 2 , the inspection window 3 is located on one side of the edging frame 1, the grinding mechanism 4 is located in the inspection window 3 and connected with the edging frame 1, the edging frame 1 is the main structure of the equipment, and on the one hand, it serves as the shell of the equipment The structure provides protection for other associated components. On the other hand, it serves as a carrier structure for equipment control elements to allow other structures to be installed on the equipment. The internal hollow structure layer formed based on the external box structure is used as a rubber bushing workpiece. In the processing platform area, the control panel 2 can realize the operation command and parameter ac...

Embodiment 2

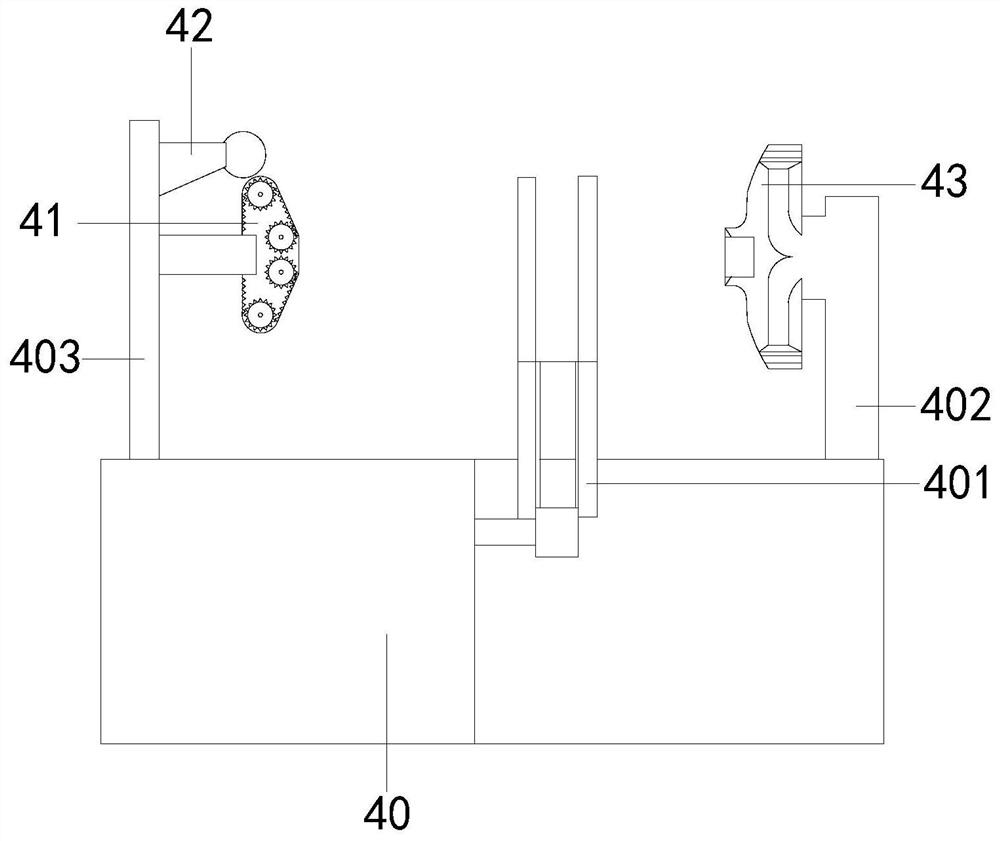

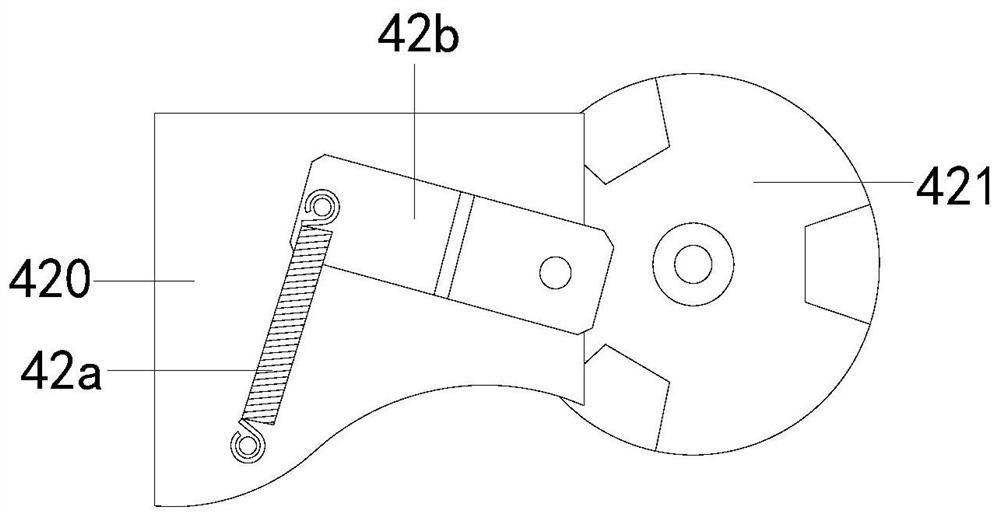

[0031] The description of the second embodiment drawn in conjunction with the first embodiment, combined with figure 2 , image 3 , Figure 5 and Figure 6 One side of the prime mover 40 is connected to a polishing disc 41, a lubricating wheel 42 is arranged at intervals above the polishing disc 41 and a cutting disc 43 is correspondingly provided on one side thereof, and one end of the swing seat 420 is fitted with an intermittent oiler 421 and the two are connected One end of the rotary cutting disc 430 is provided with a connection hole 431 and a chip removal groove 432 is opened on the back thereof. The body 4301 is externally connected to the scraper guide ring 4304. When processing the rubber bushing, the bushing is clamped and fastened by turning over the clamp rod 40 first, and the position of the end face is adjusted according to the processing requirements, and the rubber bushing is matched with the polishing disc 41 and the cutting disc 43. The edge of the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com