Inhaul cable device for whole-hole span-by-span construction of reinforced concrete composite beam

A technology of steel-concrete composite beam and winding device, which is applied in bridges, bridge construction, erection/assembly of bridges, etc. The effect of connecting, enhancing the bearing capacity, and improving the pulling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

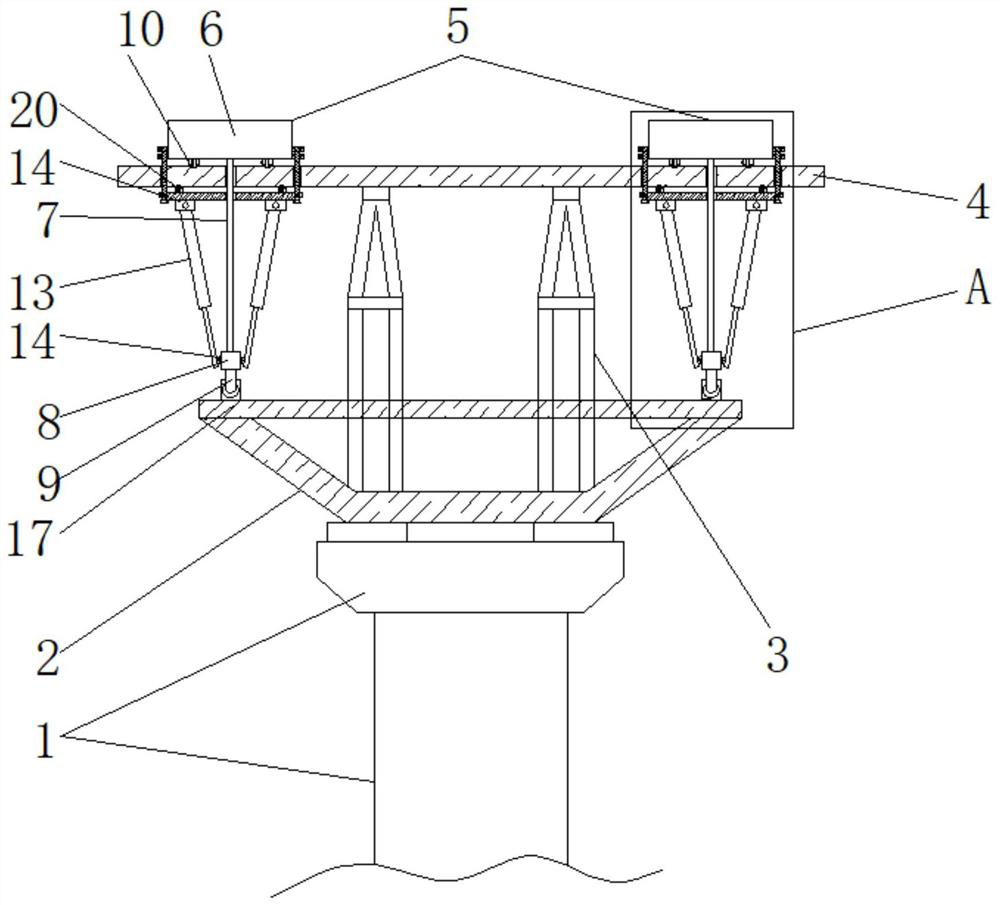

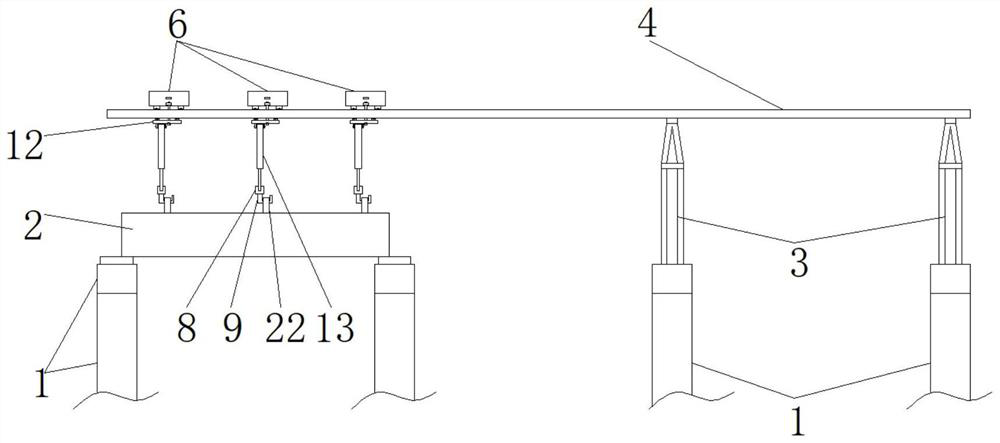

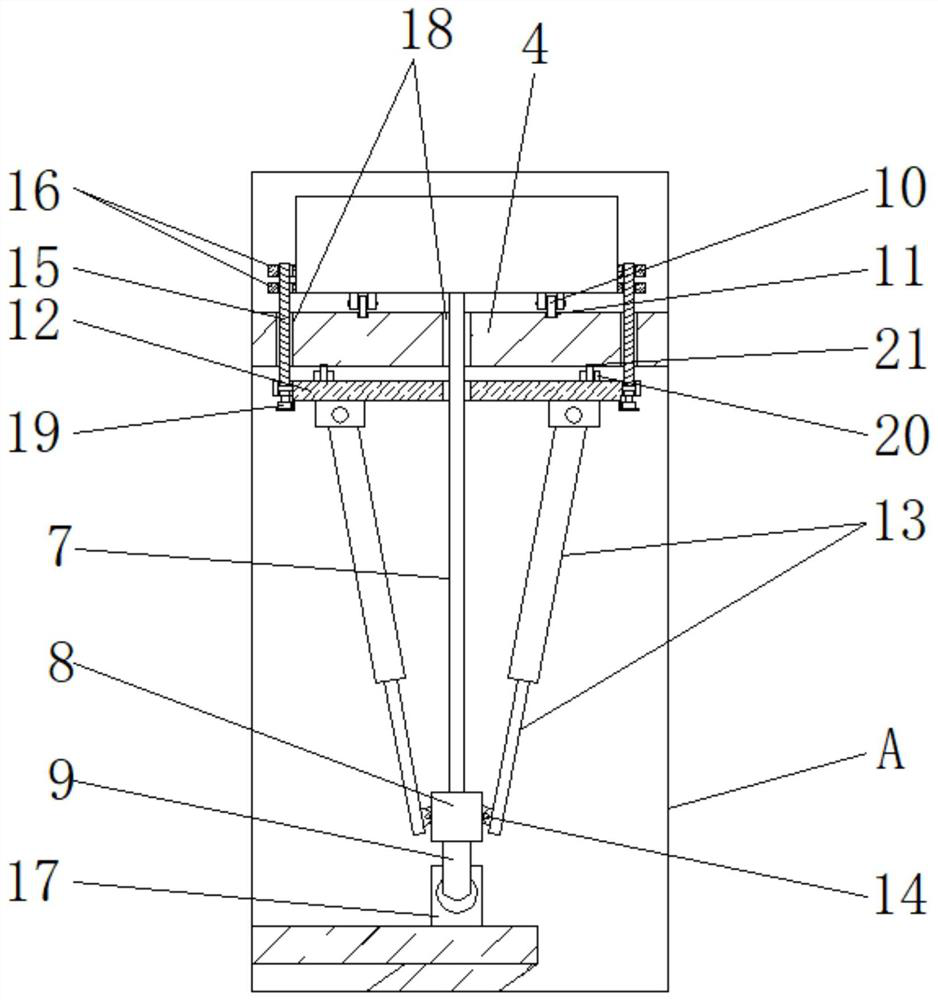

[0026] Such as Figure 1-3 The shown cable device for the span-by-span construction of the whole hole of the steel-concrete composite beam includes a bridge pier 1, and the girder box 2 is erected on the top of the bridge pier 1 through a bridge erecting machine, and the bridge erecting machine beam 4 on the bridge erecting machine passes through The bracket 3 is arranged directly above the pier 1, and the crossbeam 4 of the bridge erecting machine is provided with at least three sets of cable mechanisms 5 for pulling the flanges on both sides of the top of the girder box 2, and each set of cable mechanisms 5 There are two cable mechanisms 5, and each group of two cable mechanisms 5 is symmetrical with respect to the vertical center line of the pier 1. The cable mechanism 5 includes a winding device with a cable 7, and connects the cable 7 through a connecting block 8. The hook 9 connected by the free end, the housing bottom of the winding device is slidably connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com