Threaded clamping and pressing type pipe structure and using method thereof

A compression-type pipe fitting and thread technology, which is applied in the direction of pipe/pipe joint/pipe fitting, through element, sealing surface connection, etc., can solve the problems of large wear of O-ring rubber ring, loss of rebound ability of gasket, and shortened service life. , to achieve the effect of high tensile strength, excellent temperature resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

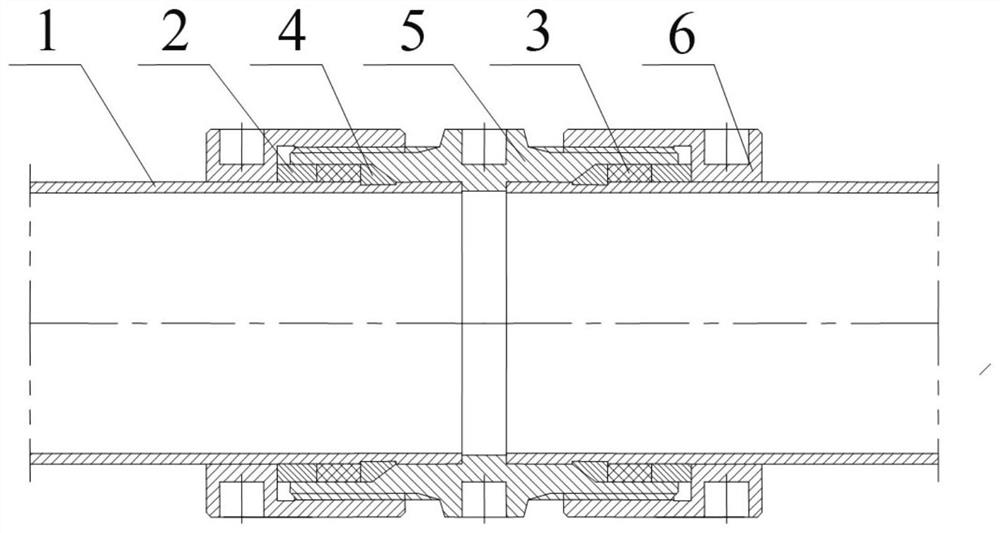

[0078] Such as Figure 1-4 As shown, a thread clamping pipe fitting structure includes a joint body 5, a pipe body 1, a nut 6 and a sealing assembly;

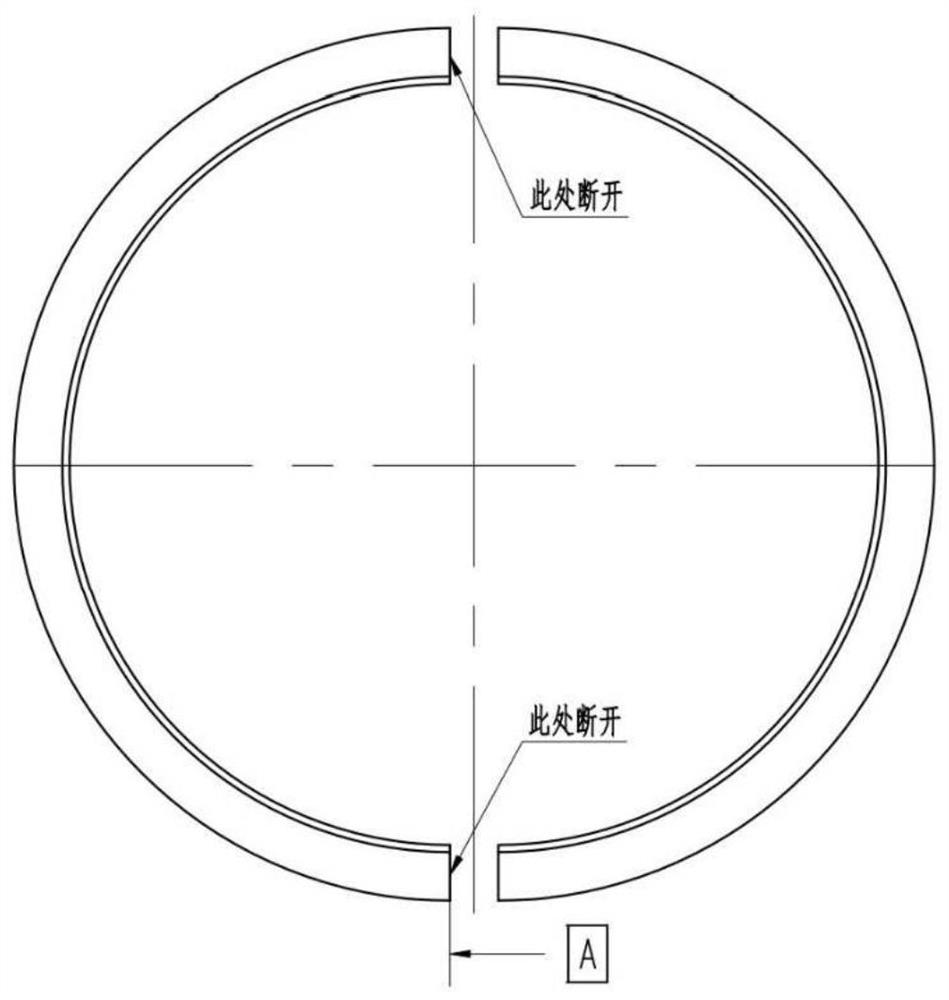

[0079] The joint body 5 includes a pipe body accommodation section and a seal assembly accommodation section; the pipe body 1 accommodation section is provided with a positioning spigot, and the seal assembly accommodation section is provided with a seal assembly accommodation cavity; the outer wall of the seal assembly accommodation section is provided with an external thread , the accommodating section of the sealing assembly is threadedly connected with the nut 6; the sealing assembly is placed in the accommodating chamber of the sealing assembly; in the accommodating chamber of the sealing assembly of the joint body 5, along the axial direction of the joint body 5, a cone is set away from the end of the nut 6 section, the seal assembly includes pressure ring 2, packing seal ring 3 and cone ring 4 arranged in sequence; cone ...

Embodiment 2

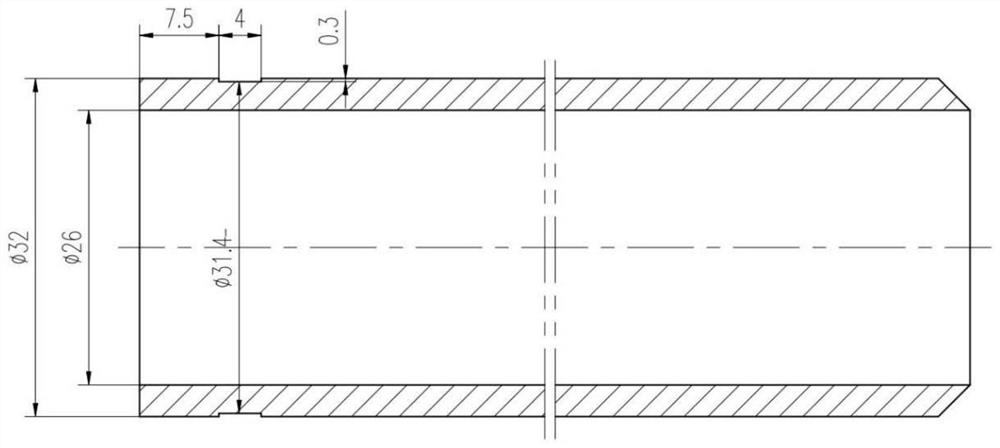

[0096] Compared with Example 1, it is only different in pipe diameter D, annular groove depth t, and annular groove width d, specifically, as Figure 2-3 As shown, pipe diameter D=32mm, annular groove depth t=0.3mm, annular groove width d=4.0mm, such as Figure 4 As shown, the size of the tapered ring matches the annular groove. Using the same test conditions and standards as in Example 1, the sealing device equipped with a φ32×1.2 pipe body is tested, and it still meets the service conditions under a pulling force of 25kN, and the sealing device has no leakage or falling off.

Embodiment 3

[0098]Compared with Example 1, it is only different in pipe diameter D, annular groove depth t, and annular groove width d, specifically, pipe diameter D=50.8mm, annular groove depth t=0.4mm, annular groove width d=6.0mm, for the performance test of the sealing device after the nut is tightened, the same test conditions and standards as in Example 1 are adopted, and the sealing device equipped with a φ50.8×1.2 pipe body is tested. Meet the conditions of use, and the sealing device has no leakage or falling off.

[0099] For pipes with a pipe diameter between 22-57mm, the sealing device of the present invention is used. After testing, the tensile strength is significantly higher than the standard requirement. The tensile force can reach 150%-200% of the standard requirements. As shown in Table 1, under the test tensile force of 150%-200% of the tensile force standard requirements, the sealing device has no leakage and no shedding. It should be noted that the table The tensile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com