Electromagnetic heating heavy oil conveying pipe integrating electromagnetic heating and oil conveying and using method of electromagnetic heating heavy oil conveying pipe

A technology for heating heavy oil and oil pipelines, applied in induction heating, induction heating devices, pipeline systems, etc., can solve the problems of heating pipelines limited by water depth, difficult operation of heating pipes, and low heating efficiency, so as to improve underwater installation and operation Efficiency, convenience for underwater installation operations, and the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

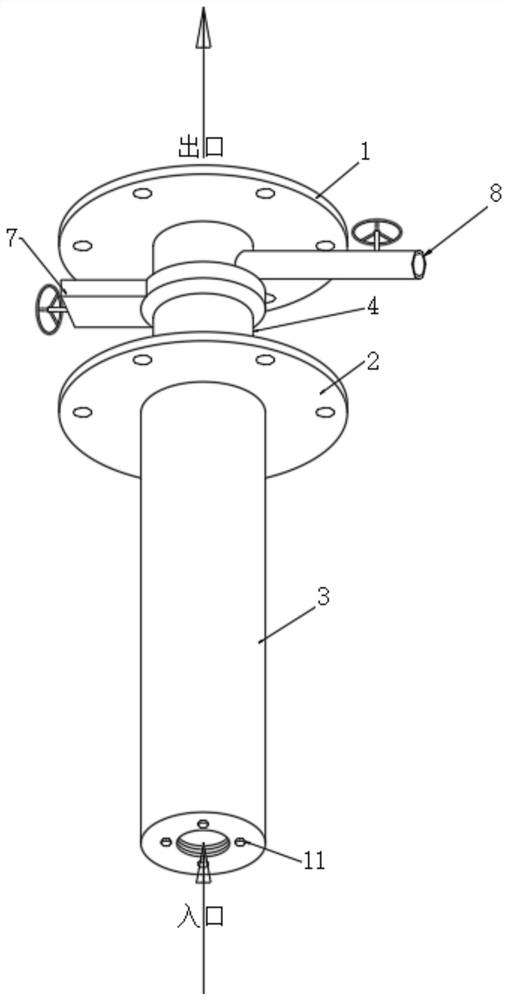

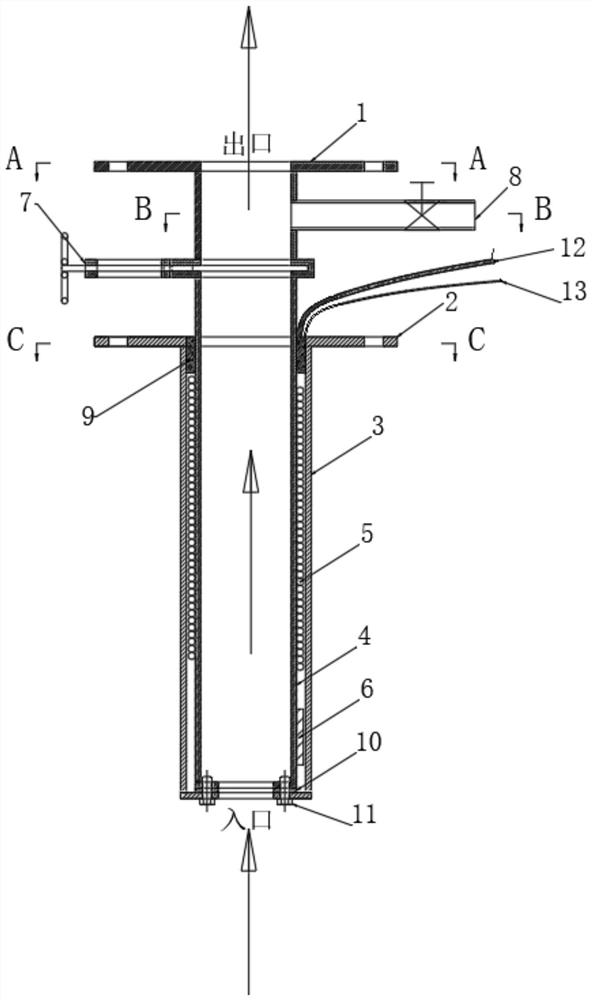

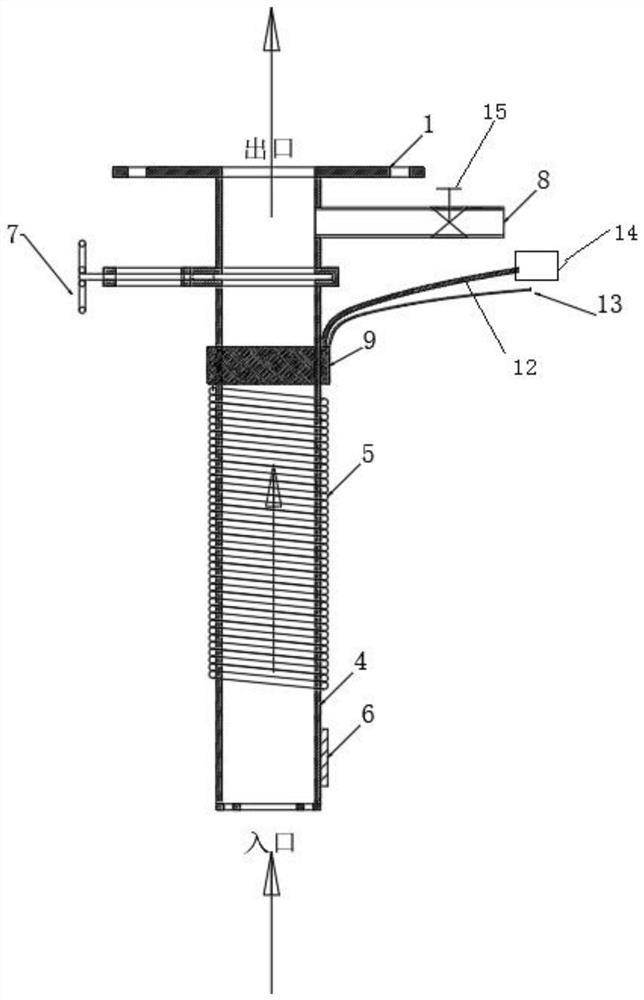

[0039] Such as Figure 1-7 As shown, an electromagnetically heated heavy oil delivery pipe integrating electromagnetic heating and oil delivery includes a steel inner tube 4, the steel inner tube 4 is covered with a steel tubular shell 3, and the inner wall of the steel tubular shell 3 is in contact with the Between the outer walls of the steel inner tube 4 there is at least one high temperature resistant waterproof insulated electric coil 5 wound on the outer wall of the steel inner tube 4 , the top end of the steel inner tube 4 extends upward and is fixedly installed with The first flange 1, and the top end of the steel tubular shell 3 is fixedly installed with the second flange 2, and the steel inner tube 4 is between the first flange 1 and the second flange 2 A knife valve 7 is installed in the part of the inner tube 4, and the bottom of the steel inner tube 4 and the bottom of the steel tubular shell 3 are sealed by a sealing rubber gasket 10, and are fixed as a whole by ...

Embodiment 2

[0045] Such as Figure 1-7 As shown, a method for using an electromagnetically heated heavy oil pipeline that integrates electromagnetic heating and oil delivery includes the following steps:

[0046] S1: At least one penetration hole is opened on the heavy oil tank 16 of the sunken ship, and the bottom of an electromagnetically heated heavy oil delivery pipe for electromagnetic heating and oil delivery is inserted into the heavy oil tank of the sunken ship through the penetration hole, and the second flange 2 is connected to the heavy oil tank of the sunken ship. The heavy oil tank 16 of the sunken ship is fixedly connected by bolts;

[0047] S2: The first flange 1 is fixedly connected to the screw pump 17 for pumping heavy oil through bolts; the air intake pipe 8 is connected to the high-pressure air machine 18;

[0048] S3: the terminal 12 of the high temperature-resistant and waterproof insulated electric coil 5 and the terminal 13 of the temperature sensor 6 are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com