Sampling device for wastewater quality detection

A water quality detection and sampling device technology, applied in the sampling device and other directions, can solve the problems of polluting people's hands, uneven sampling samples, etc., and achieve the effect of accurate and stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

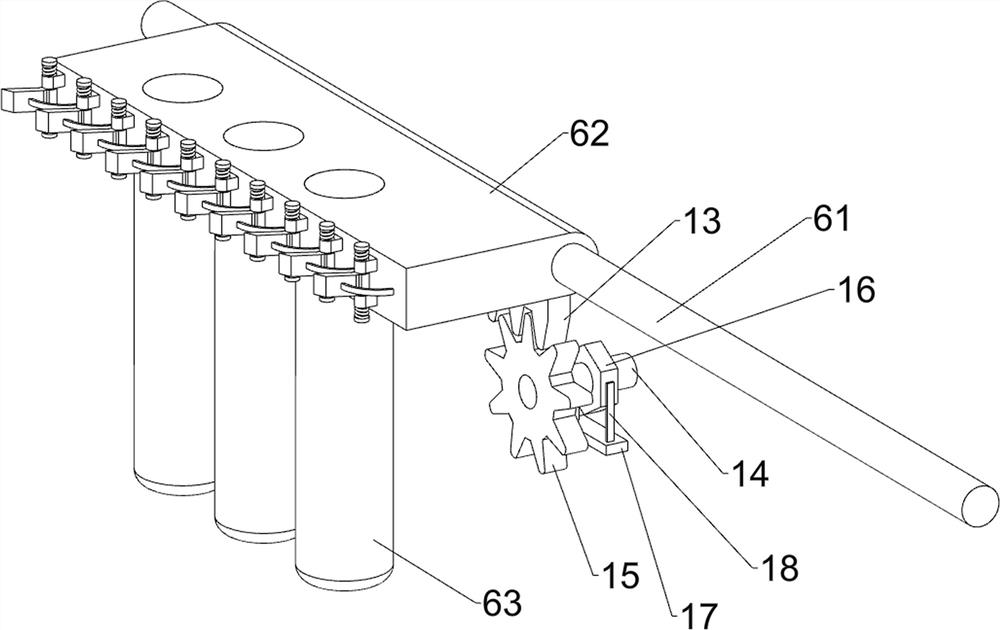

[0021] A sampling device for sewage water quality testing, such as Figure 1-4 As shown, it includes a box 1, a fixed block 2, a handle 3, a square box 4, a hydraulic water suction mechanism 5 and a moving mechanism 6, the front side of the box 1 is provided with a fixed block 2, the front side of the fixed block 2 is provided with a handle 3, and the handle 3 The upper end is provided with a square box 4, the fixed block 2 is provided with a hydraulic water suction mechanism 5, and the box 1 is provided with a moving mechanism 6.

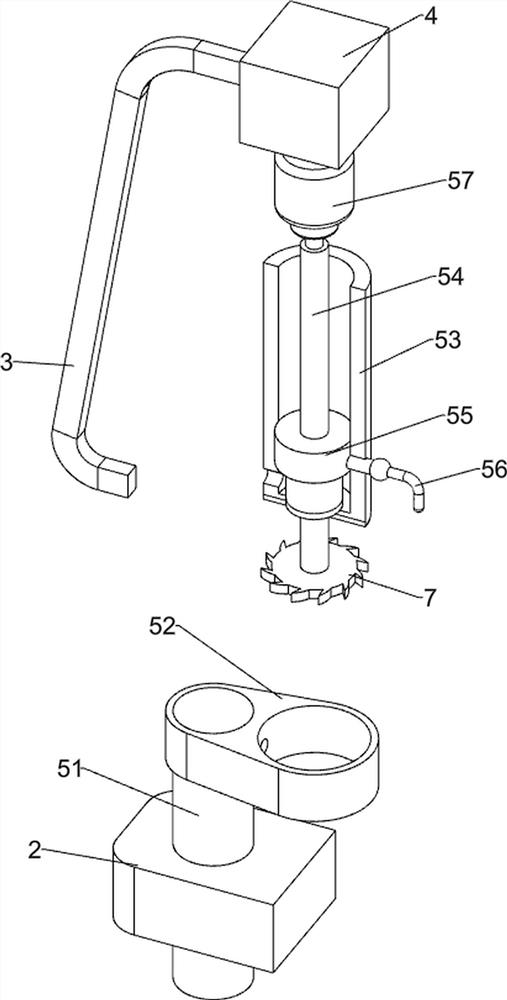

[0022] The hydraulic water suction mechanism 5 includes a guide tube 51, a connecting block 52, a cylinder body 53, a screw mandrel 54, a piston 55, a water nozzle 56 and a servo motor 57, the fixed block 2 is provided with a guide tube 51, and inside the guide tube 51 Contains a one-way valve and is provided with a scale on its outside, a connecting block 52 is provided on the upper end of the guide tube 51, and a cylinder 53 is provided on the re...

Embodiment 2

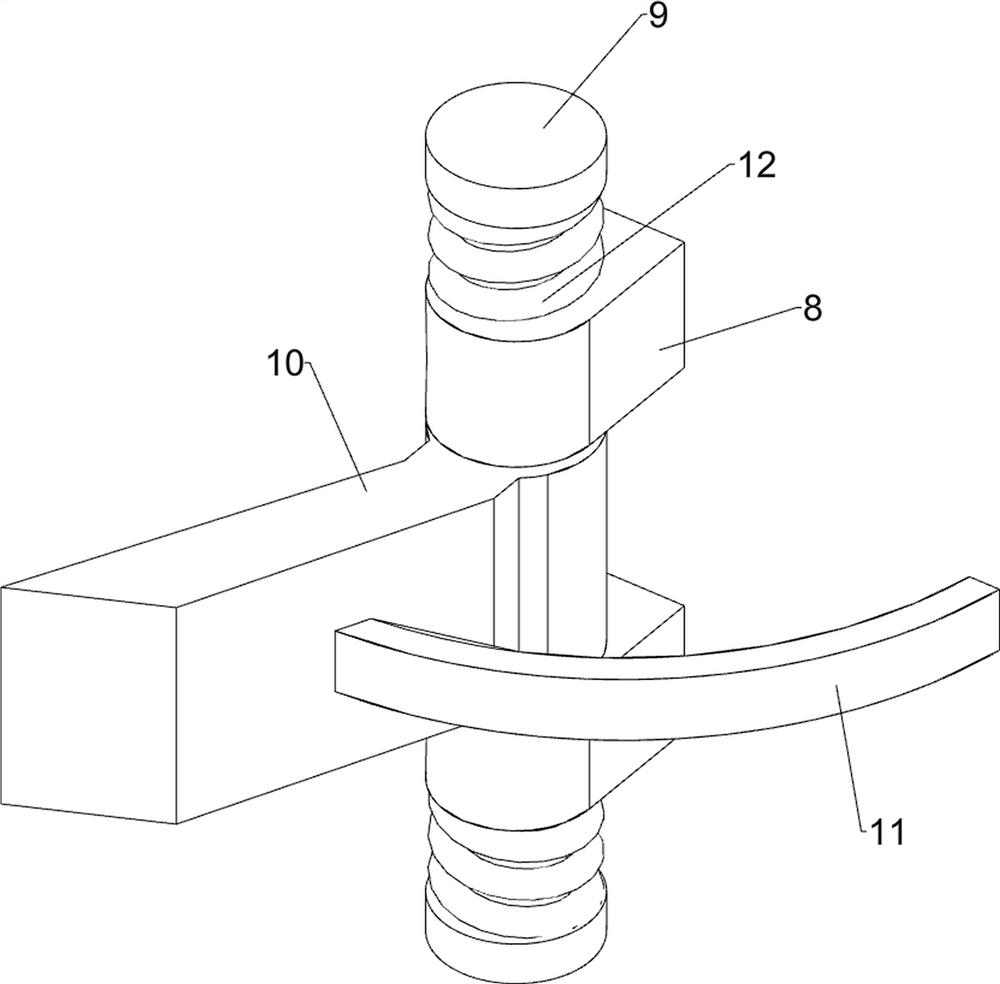

[0026] Such as Figure 4 As shown, on the basis of Embodiment 1, a sampling device for sewage water quality detection also includes a ratchet 7, a sector block 8, a connecting shaft 9, a ratchet 10, a top sheet 11 and an elastic member 12, and the lower end of the screw rod 54 A ratchet 7 is provided, and the front side of the moving block 62 is evenly arranged with fan-shaped blocks 8 symmetrically spaced about the center line of the moving block 62, and the upper and lower fan-shaped blocks 8 are rotatably provided with connecting shafts 9, and the middle parts of the connecting shafts 9 are provided with ratchets 10. Top pieces 11 are evenly spaced on the front side of the moving block 62 , and the front ends of the top pieces 11 are all in contact with the right side of the ratchet 10 , and elastic pieces 12 are provided at both ends of the connecting shaft 9 .

[0027] During the forward rotation of the screw mandrel 54, the forward rotation of the screw mandrel 54 will d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com