Device and method for nondestructive measurement of hydrogen content in solid steel

A hydrogen content, solid technology, applied in the direction of measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of small hydrogen diffusion coefficient, slow measurement speed, uneven distribution of hydrogen, etc., and achieve simple test steps, test Accurate, fast testing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

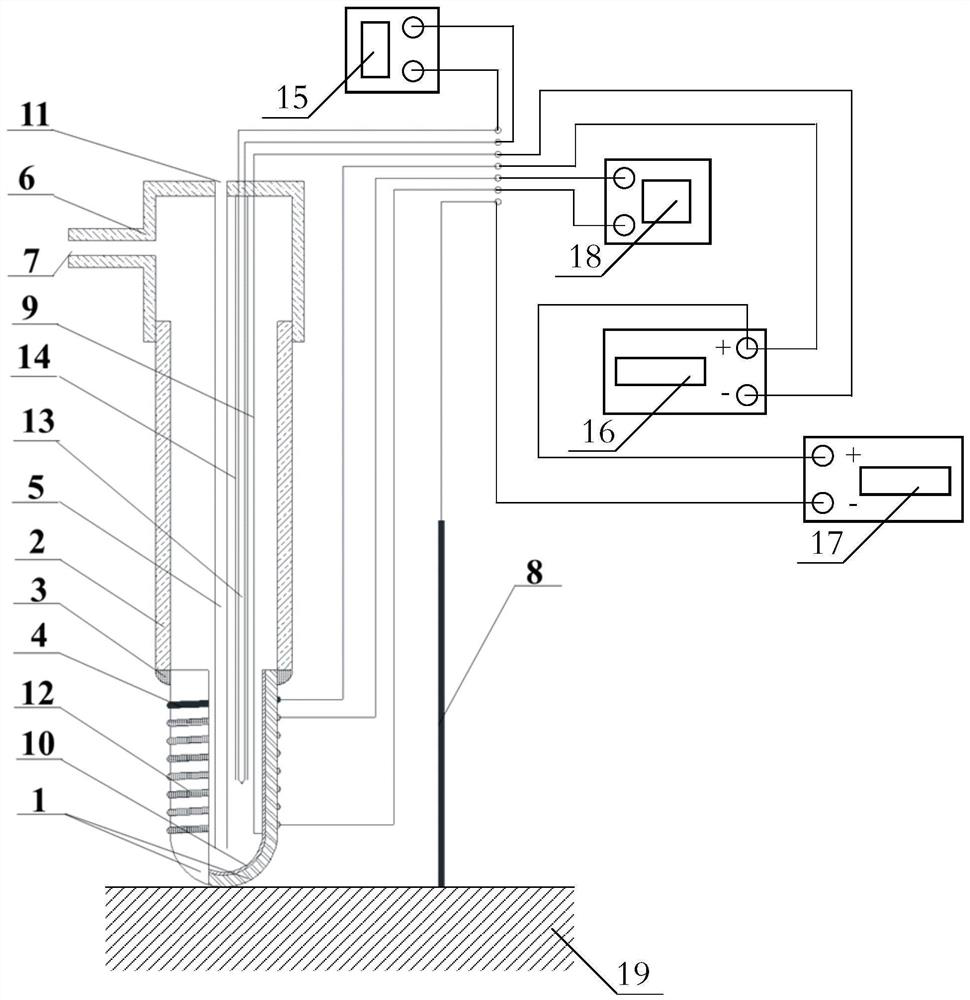

[0077] The structure of the device for non-destructive measurement of hydrogen content in solid steel is as follows figure 1 As shown, it includes a high-temperature proton conductor 1, a support tube 2 and a sealing cover 6;

[0078] The high-temperature proton conductor 1 is barrel-shaped, the outer wall is coated with a porous electrode 4 and the auxiliary thermal electrode 12, and the inner wall is coated with a reference electrode 10; the top of the high-temperature proton conductor 1 and the bottom end of the support tube 2 are sealed and bonded by a high-temperature adhesive 3 fixed together;

[0079] The support pipe 2 is cylindrical, and the top end is sealed and fixed with the sealing cover 6; the sealing cover 6 is an inverted barrel shape, and the side wall is provided with an air outlet pipe 7, the air inlet pipe 5 passes through the top plate of the sealing cover 6, and the bottom of the air inlet pipe 5 The end is located inside the high temperature proton cond...

Embodiment 2

[0099] The structure of the device for non-destructively measuring the hydrogen content in solid steel is the same as in Example 1;

[0100] Method is with embodiment 1, and difference is:

[0101] (1) The reference gas is N 2 -H 2 Standard gas; solid steel material to be tested is 304 austenitic steel;

[0102] (2) The target temperature is 1000±0.5°C (1273±0.5K);

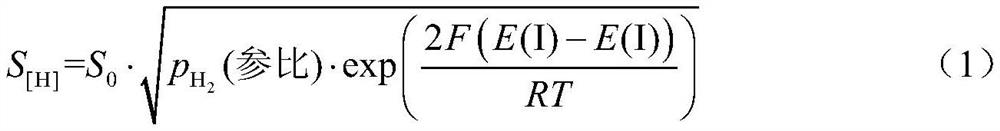

[0103] (3) The measured voltage between the inner wall and the outer wall of the high-temperature proton conductor 1 is -0.1136V, and the voltage between the inner wall of the high-temperature proton conductor 1 and the solid steel 19 to be measured is -0.0872V measured by the second voltmeter 17;

[0104] S at 1000°C 0 =5.79ml / 100g;

[0105] Measured hydrogen content S [H] = 2.33ml / 100g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com