High-brightness green light source device based on rod-shaped light conversion material

A technology of light conversion material and light source device, which is applied to optical elements, projection devices, lighting devices, etc. for changing the spectral characteristics of emitted light, can solve the problems of high cost, sudden drop in efficiency, low power density, etc. Reflection loss, improved luminous intensity, small ceramic end face effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

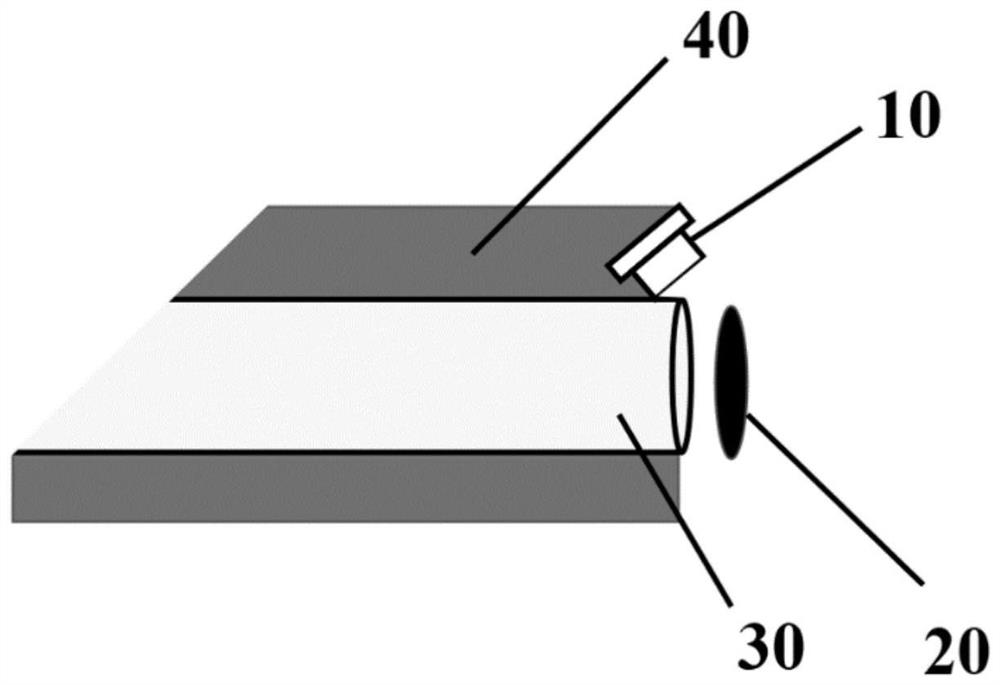

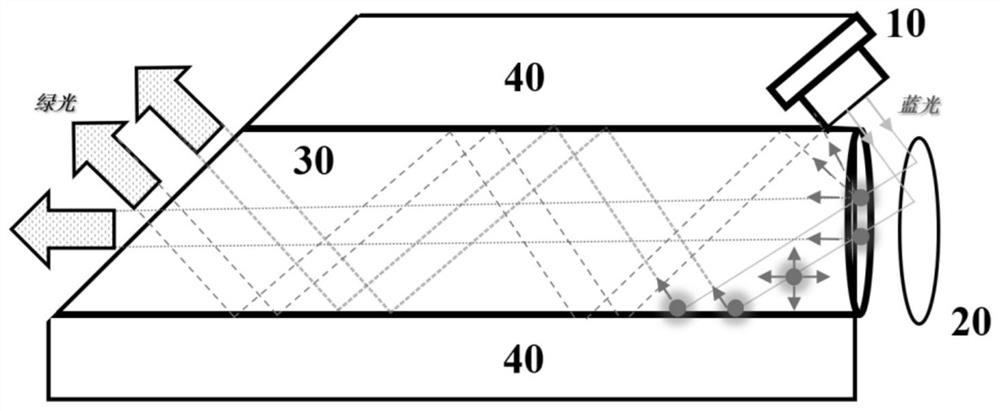

[0025] A high-brightness green light source device based on rod-shaped light conversion materials, such as figure 1 As shown, it includes a laser 10, a reflector 20, a fluorescent conversion rod 30, and a heat dissipation substrate 40; wherein,

[0026] The laser 10 is obliquely placed above the right end face of the fluorescent conversion rod 30, the angle between the light output direction of the laser 10 and the horizontal plane is 30°, and the spot radius of the laser 10 incident on the surface of the mirror 20 is 0.5mm; 20 is located on the right side of the fluorescent conversion rod 30, the radius of the reflector 20 is 6.0 mm, the distance between the reflective mirror 20 and the right end of the fluorescent conversion rod 30 is 1.0 mm, the fluorescent conversion rod 30 is cylindrical, and the left end surface is polished Slope, the direction of the polished slope is perpendicular to the light output direction of the laser, that is, the angle between the polished slope...

Embodiment 2

[0030] A high-brightness green light source device based on a rod-shaped light conversion material, including a laser 10, a reflector 20, a fluorescent conversion rod 30, and a heat dissipation base 40; wherein,

[0031] The laser 10 is obliquely placed above the right end face of the fluorescent conversion rod 30, the angle between the light output direction of the laser 10 and the horizontal plane is 40°, and the spot radius of the laser 10 incident on the surface of the mirror 20 is 1.0mm; 20 is located on the right side of the fluorescent conversion rod 30, the radius of the reflector 20 is 10.0 mm, the distance between the reflective mirror 20 and the right end of the fluorescent conversion rod 30 is 5.0 mm, the fluorescent conversion rod 30 is cylindrical, and the left end surface is polished Slope, the direction of the polished slope is perpendicular to the light output direction of the laser, that is, the angle between the polished slope and the horizontal plane is 50°,...

Embodiment 3

[0035] A high-brightness green light source device based on a rod-shaped light conversion material, including a laser 10, a reflector 20, a fluorescent conversion rod 30, and a heat dissipation base 40; wherein,

[0036]The laser 10 is placed obliquely above the right end face of the fluorescent conversion rod 30, the angle between the light output direction of the laser 10 and the horizontal plane is 33.3°, and the spot radius of the laser 10 incident on the surface of the reflector 20 is 0.8mm; The reflector 20 is located on the right side of the fluorescence conversion rod 30, the radius of the reflector 20 is 6.0 mm, and the distance between the reflector 20 and the right end of the fluorescence conversion rod 30 is 2.0 mm; the fluorescence conversion rod 30 is cylindrical, The left end face is a polished slope, and the direction of the polished slope is perpendicular to the light emitting direction of the laser, that is, the angle between the polished slope and the horizon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| luminous flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com