Construction method for canceling settlement post-cast strip in jump warehouse operation

A construction method, a technology of job cancellation, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

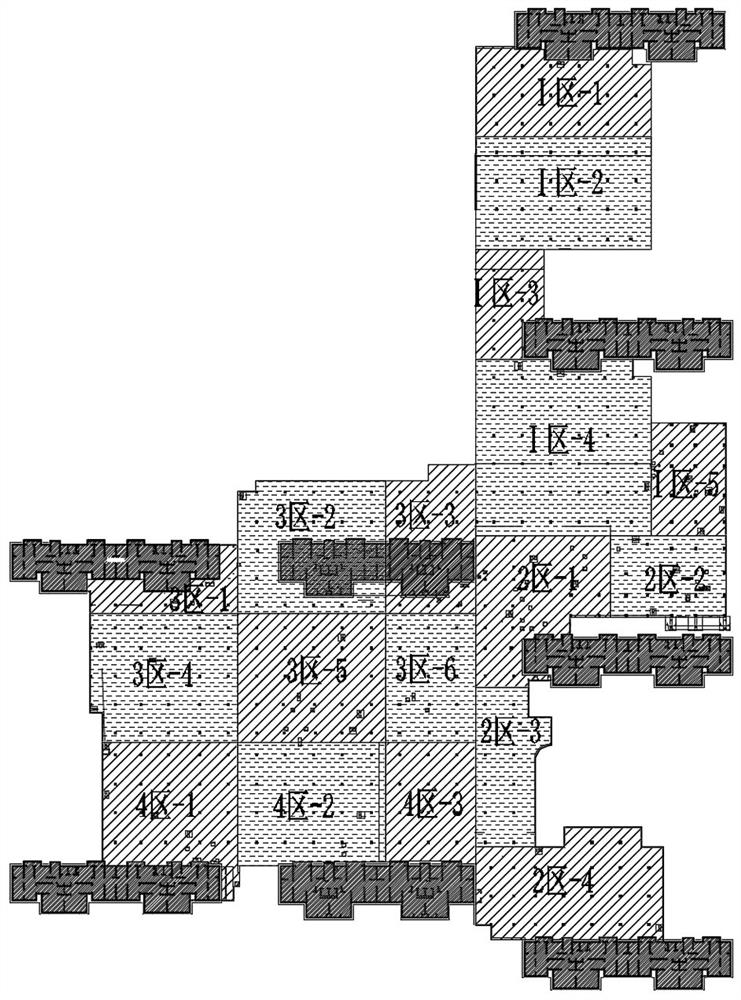

[0066] Take a certain three types of construction projects as examples. Case 1 is that the garage of the building has two floors underground, and the main building has three floors underground. The foundation floor and roof of the garage are ultra-long structures, the thickness of the foundation floor is 500mm, the concrete strength is C30, and the impermeability grade is P8. The main building is located in the garage, the thickness of the raft is 600mm, the concrete strength is C30, and the impermeability grade is P8. The post-casting belts in the garage are criss-crossed irregularly, and the foundation floor alone exceeds 1183 meters. The on-site post-casting belt is divided into settlement post-casting belt and shrinkage post-casting belt. The settlement post-casting belt mainly prevents cracks from uneven settlement of the main building and garage during construction. The shrinkage post-casting belt mainly prevents temperature shrinkage cracks. The specific design overview...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com