The method and application of optimizing siliceous materials based on xrd

A material and silicon technology, applied in the field of material quality judgment, can solve time-consuming and labor-intensive problems, achieve the effects of reducing energy consumption, reducing carbon dioxide emissions, and increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

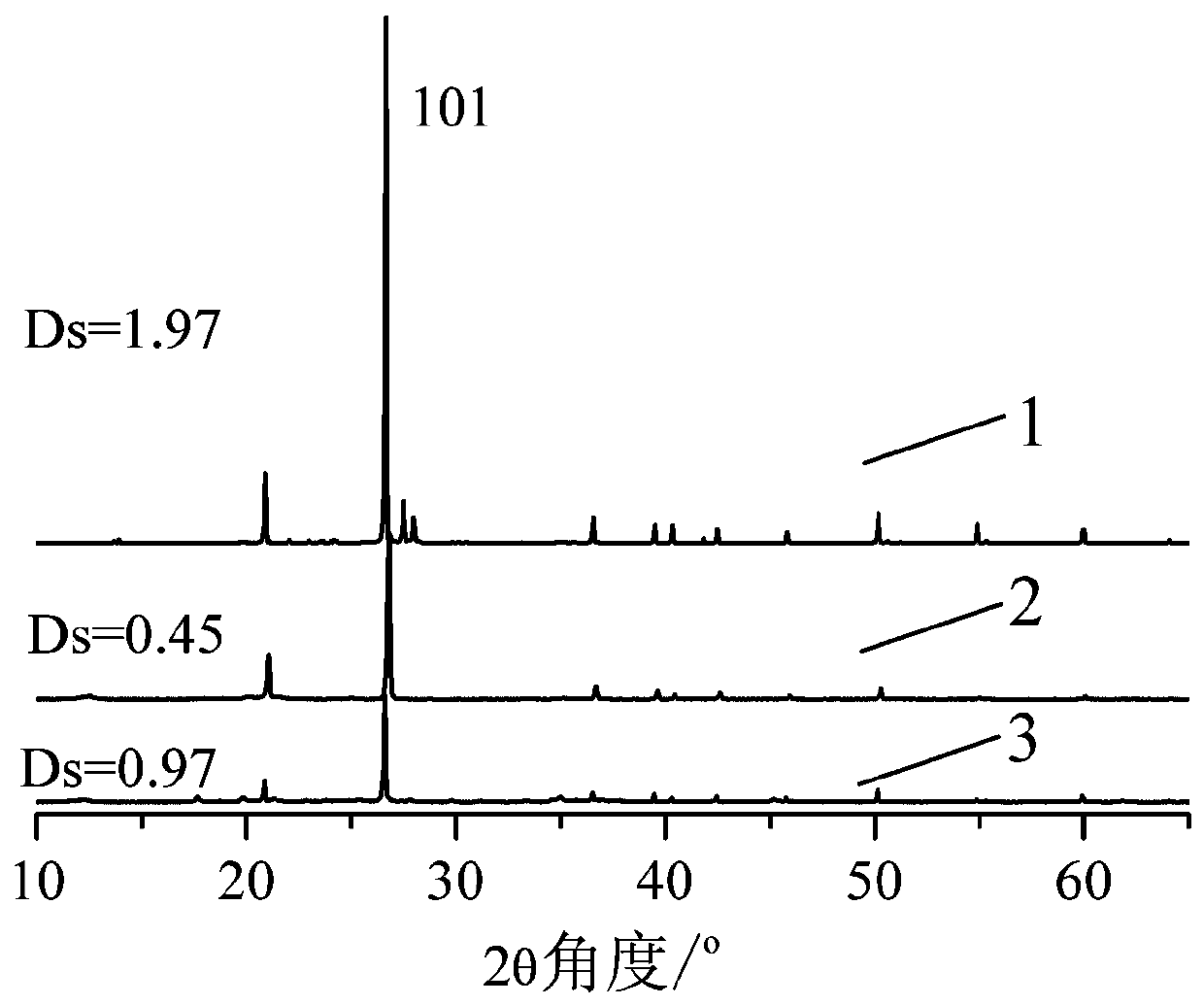

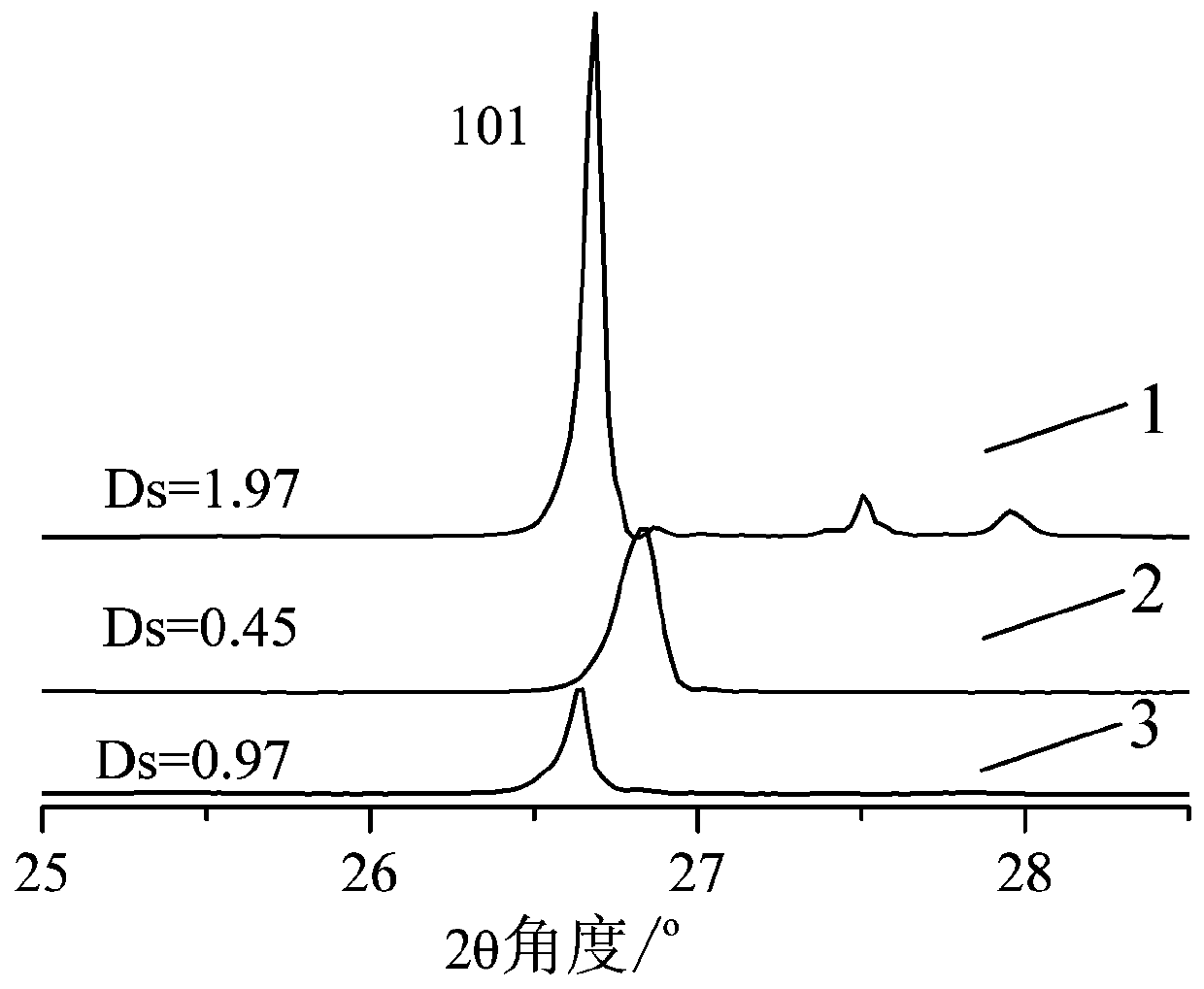

Embodiment 1

[0049] The chemical compositions of the three siliceous raw materials including quartz sand 1, high-silica sandstone 2 and medium-silica sandstone 3 are shown in Table 1-1. The raw materials are pulverized and ground, and the particle size of 80 μm is controlled to be less than 10%. By slow scanning (or increasing the power of the instrument), etc. (the measurement conditions in this example are: D8ADVANCE type, X-ray diffractometer (XRD), LynxEye one-dimensional array detector, 40kw, 250mA, Cu Kα 1,2 Diffraction, step size 0.01°, scanning speed 8° / min. ), so that in the XRD diffraction results of all samples, the diffraction peak intensity of the quartz 101 crystal plane (ie, near θ=26.64 degrees) is not less than 10,000 data points. The XRD diffraction patterns of the three siliceous raw materials are shown in figure 1 . First, the ratio R of the absolute intensity of the diffraction peak of the 101 crystal plane to the total intensity was calculated; secondly, the XRD da...

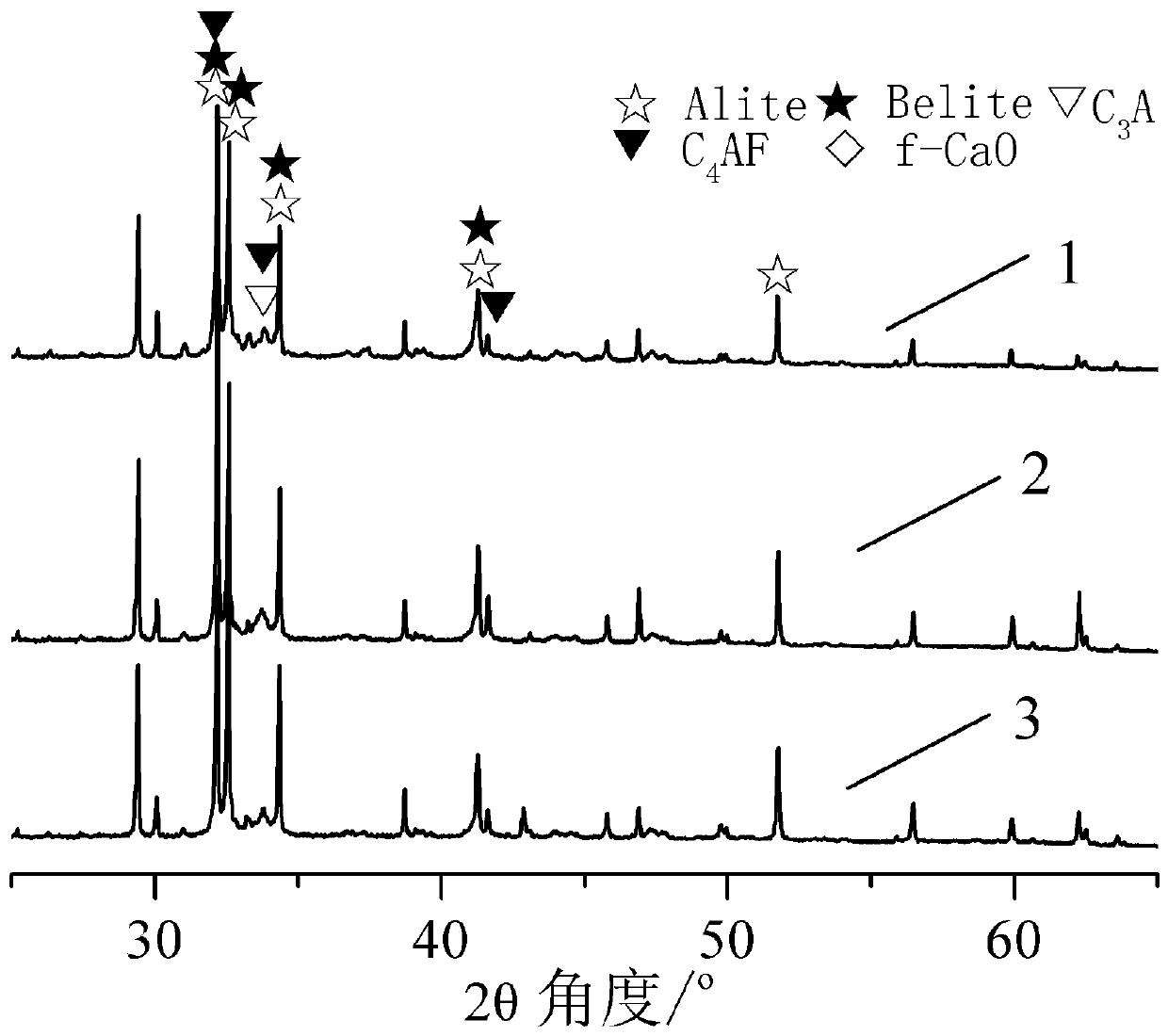

Embodiment 2

[0060] The chemical compositions of the four siliceous raw materials are shown in Table 2-1. Among them, the first beneficiation waste rock 6 and the second beneficiation waste rock 5 are due to SiO 2 If the content is low, it needs to be corrected by adding high siliceous raw materials. In order to avoid the influence caused by the difference of chemical composition, SiO is used 2 The content of chemical reagents was corrected, and the introduced amounts were 24.5% and 68.7% (mass percentage) of the total siliceous raw materials used, respectively. The above-mentioned raw materials are pulverized and ground, and the particle size of 80 μm is controlled to be less than 10%. By slow scanning (or increasing the power of the instrument), etc. (the measurement conditions in this example are: D8ADVANCE type, X-ray diffractometer (XRD), LynxEye one-dimensional array detector, 40kw, 250mA, Cu Kα 1,2 Diffraction, step size 0.01°, scanning speed 8° / min. ), so that in the XRD diffra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com