Improved hydrofoil device

A component and hydrodynamic technology, applied to ship components, using hydrofoils to act on the surrounding water surface to reduce ship motion, rotary propellers, etc., can solve problems such as poor component efficiency, low pressure in the separation area, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

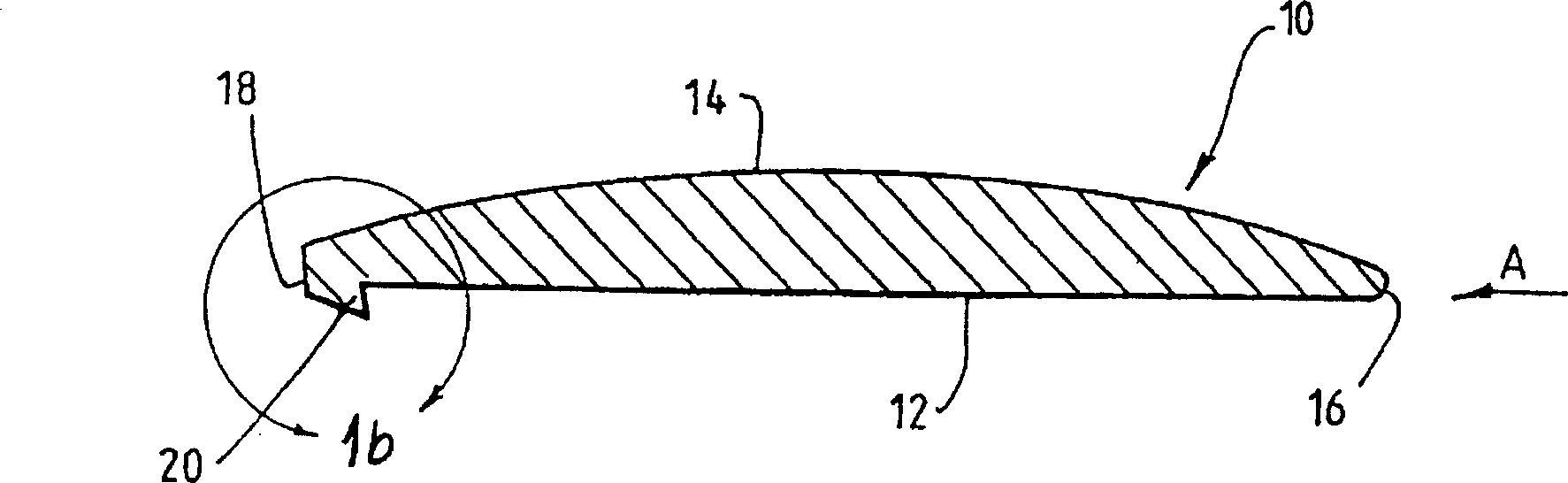

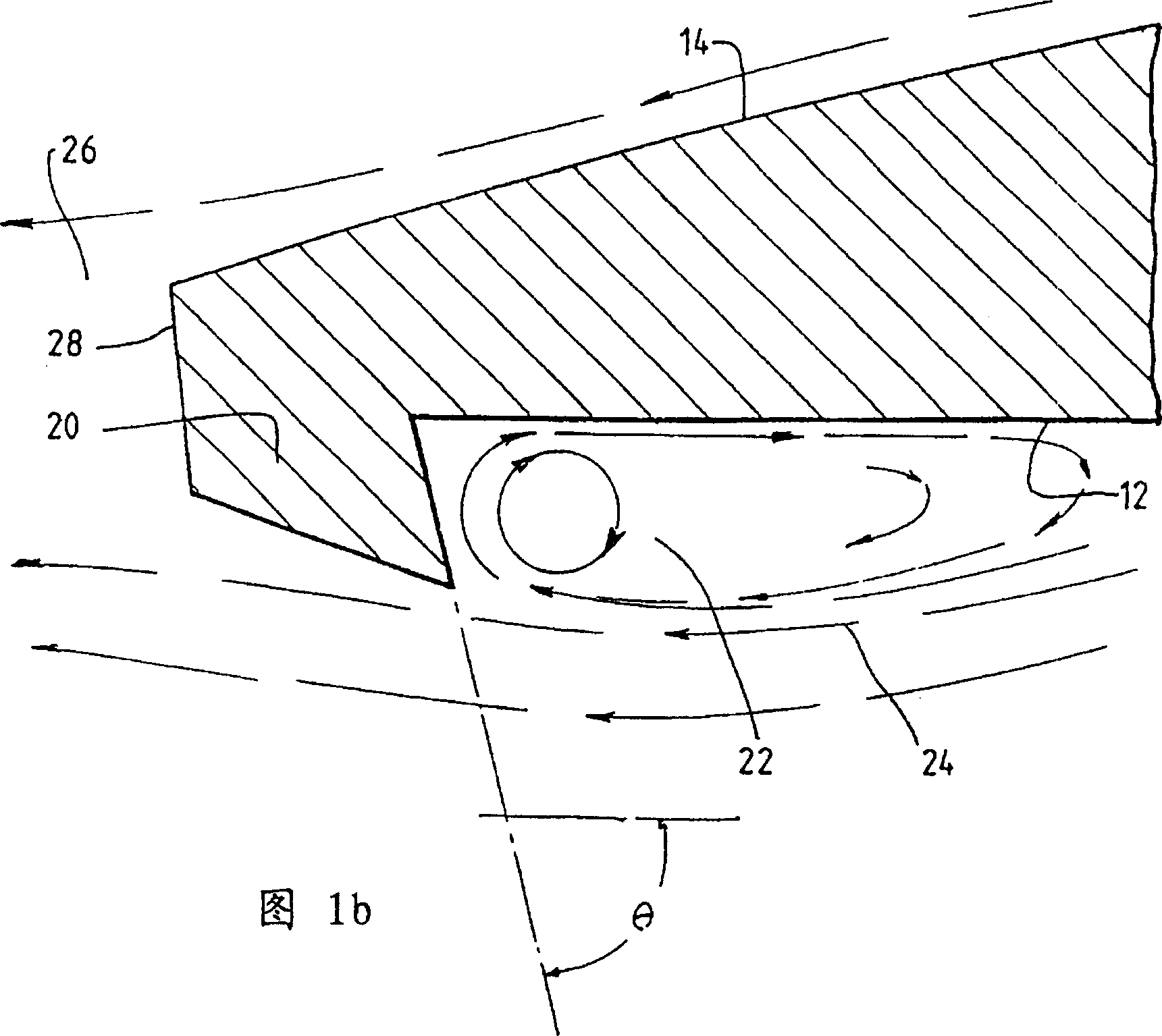

[0042] As shown in FIG. 1, a first embodiment of an improved hydrofoil 10 according to the present invention includes a first surface 12 which is subjected to a pressure greater than the surrounding local pressure. The second surface 14 is located on the other side of the hydrodynamic component. When water flows through the first surface and the second surface from the front edge 16 to the rear edge 18 of the component 10 in the direction indicated by arrow A, the pressure on the second surface 14 is generally Lower pressure than the first surface 12. A protrusion 20 is provided adjacent the trailing edge 18 , thereby forming a surface discontinuity on the first surface 12 . As can be seen more clearly from FIG. 1 b , the protrusion 20 forms an included angle θ of about 90° with the upstream direction of the hydrodynamic component, so that the water flow on the first surface 12 can turn back by itself. For this reason, the included angle θ is preferably slightly smaller than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com