PCB-passing connector capable of being observed and verified from front

A PCB board and connector technology, which is applied in the direction of connection, two-part connection device, and components of the connection device, can solve the problems of picture acquisition obstacles, unstable electrical connection, and hidden safety hazards, and achieves improved connection stability and reduced The effect of metal material consumption and rapid machine inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

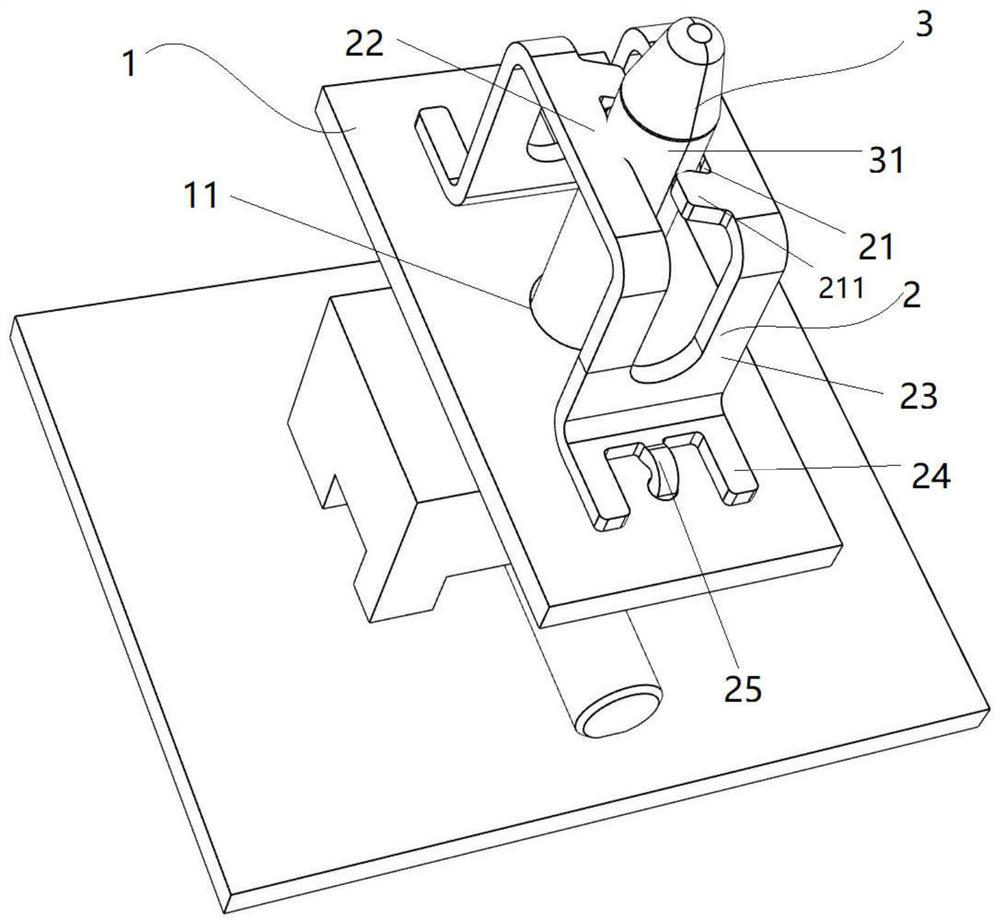

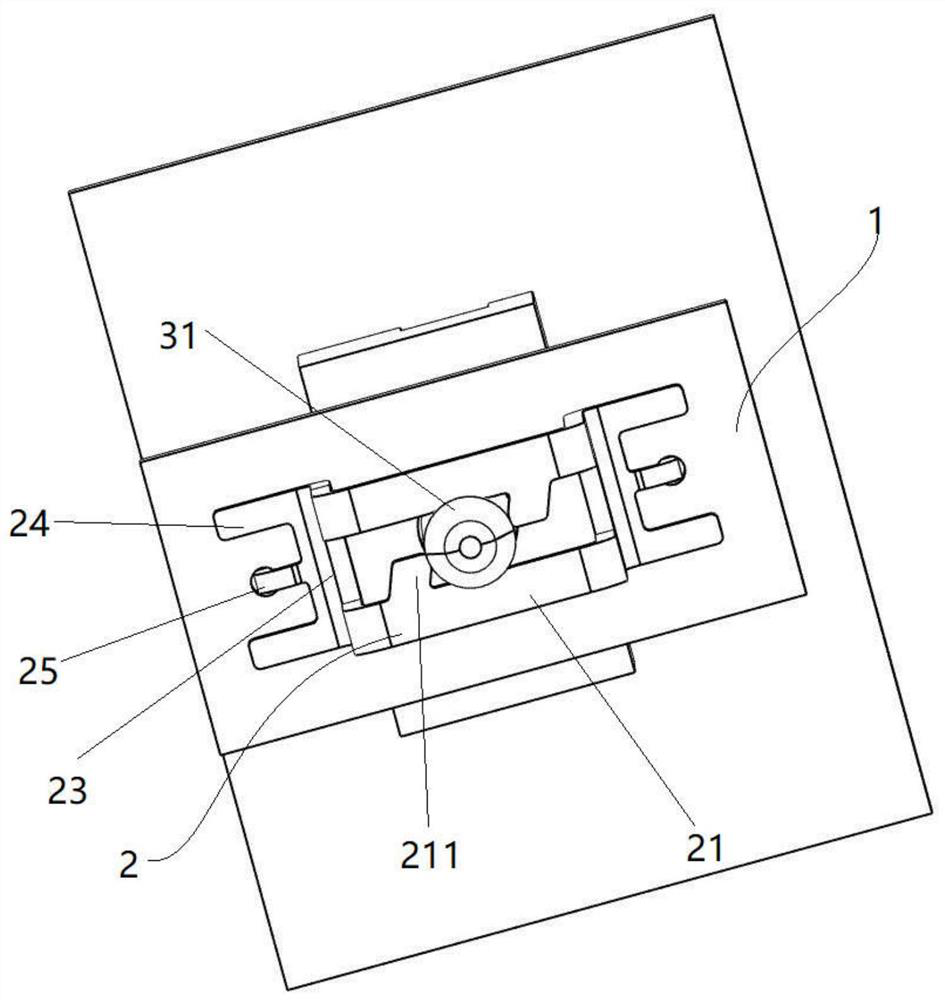

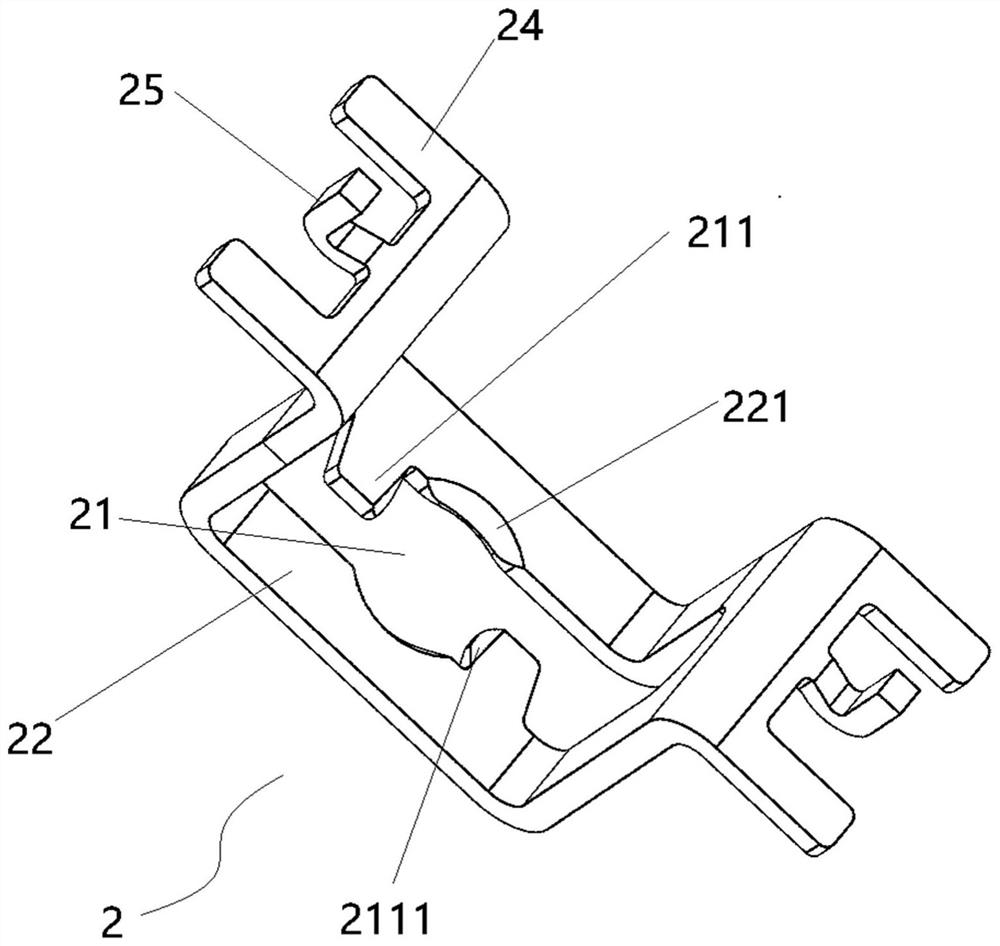

[0032] The through-PCB board connector capable of frontal observation and verification of the present invention includes a PCB board 1, an inverted U-shaped female terminal 2 and a male terminal 3, see figure 1 and figure 2 . The PCB board 1 is provided with an insertion hole 11; the two ends of the inverted U-shaped female terminal 2 are fixedly connected to the PCB board 1, and the inverted U-shaped female terminal 2 is provided with a connection hole 21; the male terminal 3 includes a A columnar connection needle 31 at the tip, the connection needle 31 first passes through the socket hole 11 and then passes through the connection hole 21, the outer wall surface of the connection needle 31 forms a 4-section contact structure with the connection hole 21, and can simultaneously The front side of the inverted U-shaped female terminal 2 realizes the positive observation verification of the 4-section contact structure.

[0033] The inverted U-shaped female terminal 2 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com