A heat pump utilising the shape memory effect

A heat pump system, memory alloy technology, applied in the heat pump field of heating system and/or cooling system, can solve problems such as low efficiency and buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

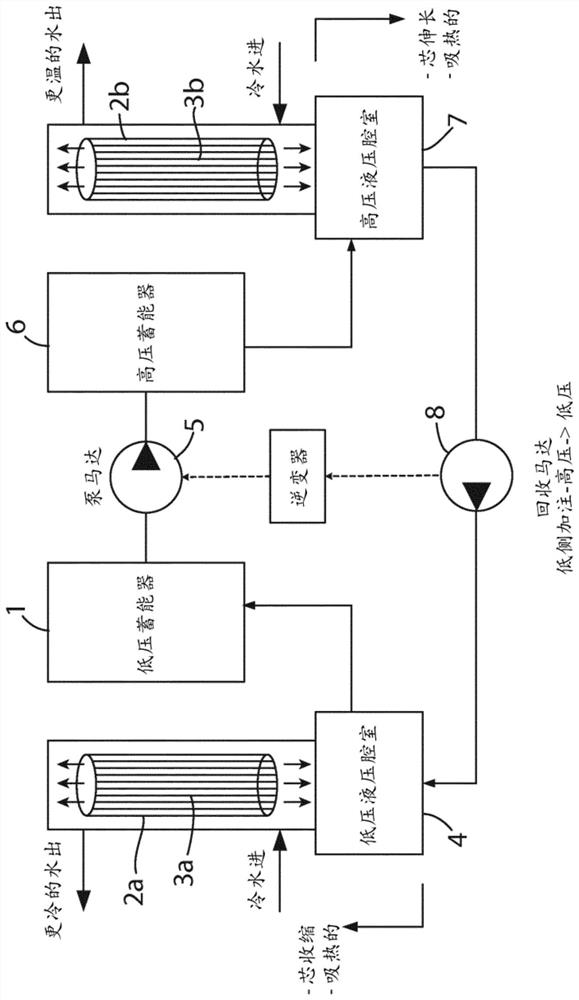

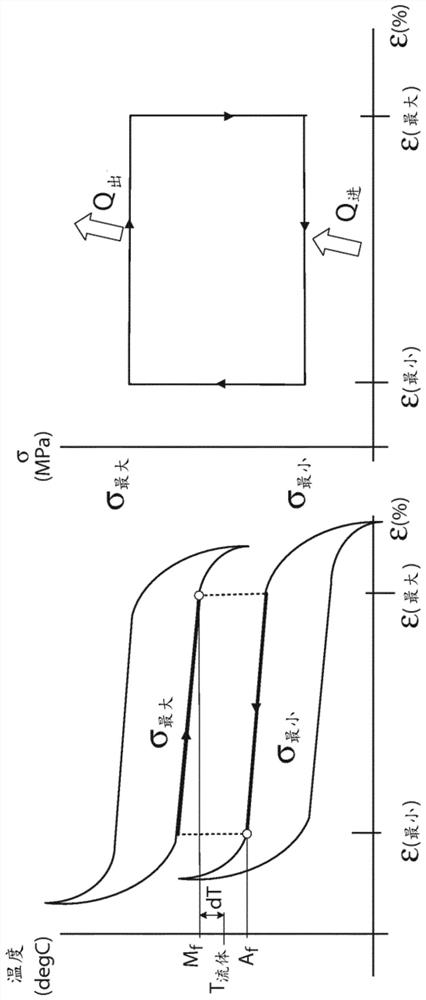

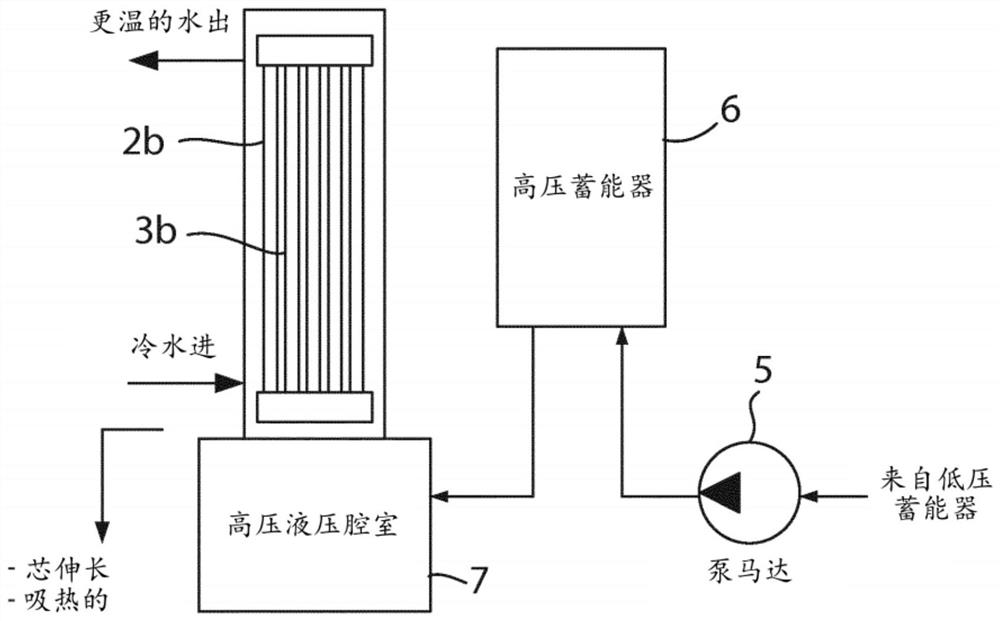

[0046] The present invention relates to a new heat pump cycle that utilizes latent heat from phase transformation of shape memory alloys ("SMA") or negative thermal expansion materials (NTE). The invention may use certain SMA motors consisting of multiple elements or wires packed together tightly to define a core. SMA materials can exist in two crystalline states, martensite and austenite, and can reversibly transform from one phase to the other. The austenite to martensite transformation of SMA is exothermic. The transformation of martensite to austenite is endothermic. The temperature at which the phase transition occurs can be controlled via applying stress to the SMA material.

[0047]A shape memory alloy (SMA) is an alloy that exhibits a shape memory effect and, once deformed, returns to its pre-deformed shape when heated. The material is a lightweight, solid-state alternative to traditional actuators such as hydraulics, pneumatics and motor-based systems.

[0048] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com