Dish washing machine and control method

A dishwasher and casing technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, household cleaning devices, etc. Easy to discharge and other problems to achieve the effect of avoiding blockage, convenient maintenance and convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

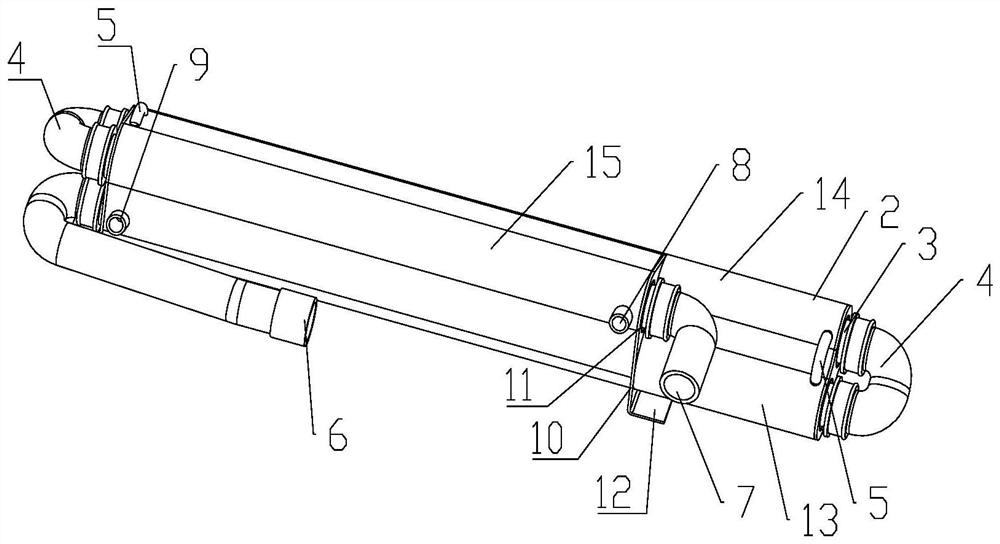

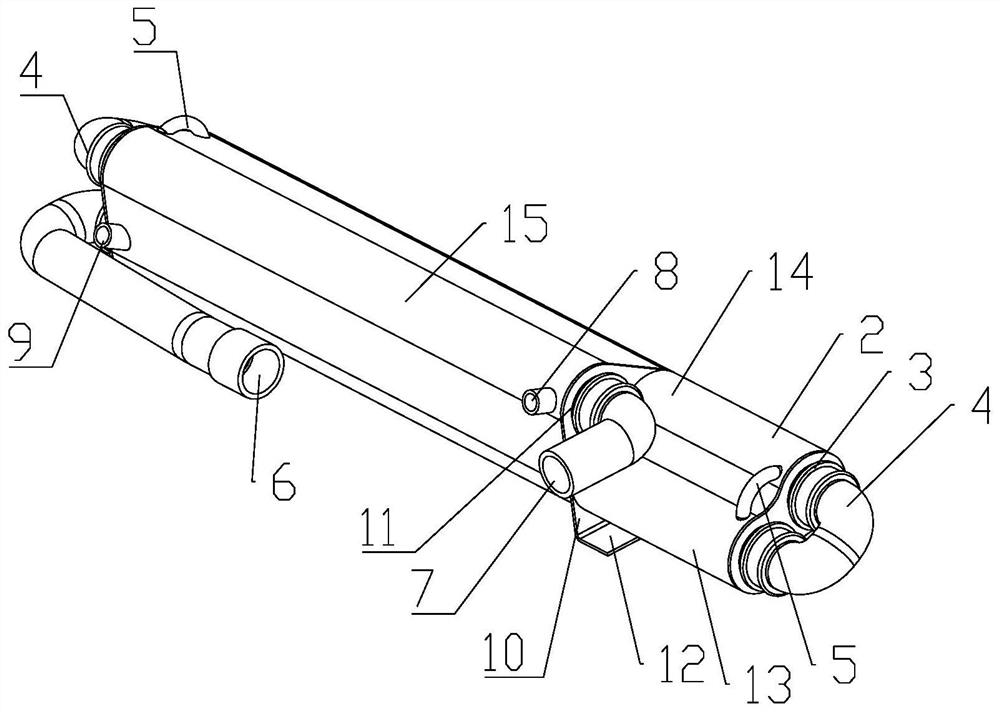

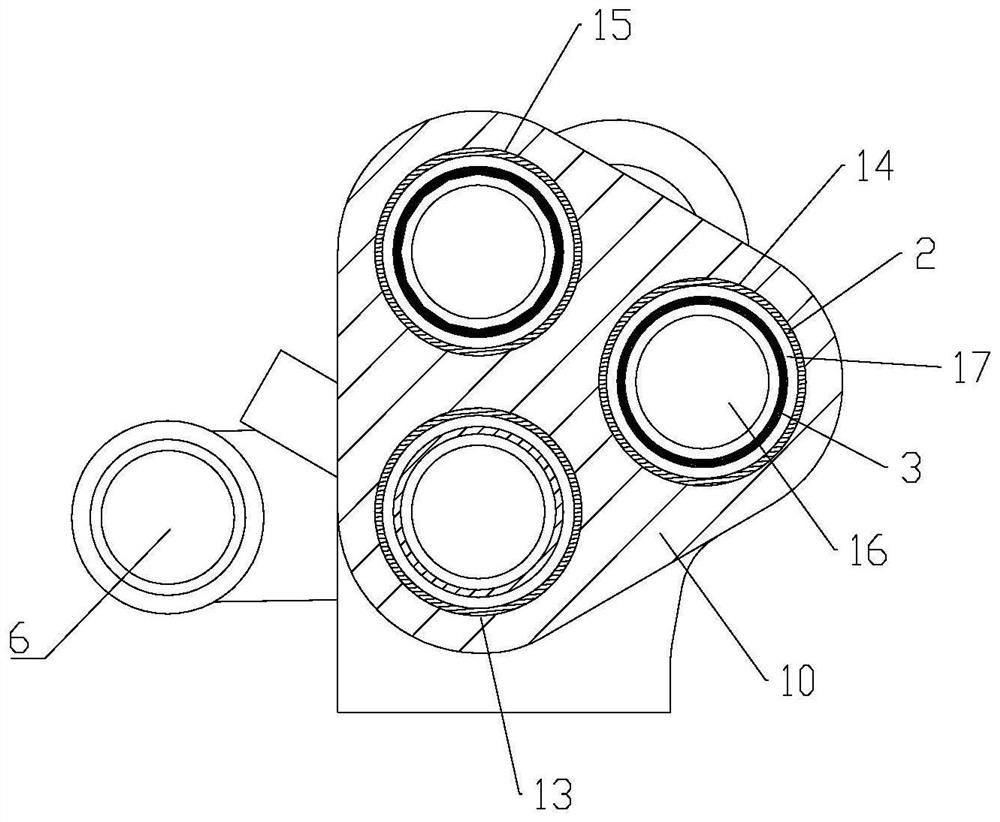

[0046] Such as Figure 1 to Figure 8 As shown, the present embodiment provides a dishwasher sleeve heat exchange device 32, comprising:

[0047] A casing, the water inlet end and / or water outlet end of the casing 1 is provided with a detachable first connection structure 4,

[0048] Or a plurality of casing pipes, different casing pipes 1 are sequentially connected through the detachable first connecting structure 4 to form a water flow channel 16 .

[0049]In this embodiment, each bushing 1 is set independently. According to the size of the dishwasher, the casing heat exchange device 32 may include one casing 1, or two casings 1 or more than two casings 1 may be sequentially connected through the detachable first connection structure 4. made. For a helical sleeve 1, the bend of the sleeve 1 is easy to accumulate foreign matter and cannot be cleaned, but in this embodiment, the first connection structure 4 between the independent sleeves 1 can be disassembled, so, The join...

Embodiment 2

[0070] Such as Figure 7 with 8 As shown, this embodiment provides a dishwasher. The dishwasher includes a housing 20. A door body 21 is arranged on one side of the housing 20. The inner tank of the dishwasher is arranged in the housing 20. The inner tank is provided with a For the spray arm, the bottom of the liner is provided with a water tank 22, a circulation pump 23 and a heat pump system.

[0071] The heat pump system of the dishwasher includes a sleeve heat exchange device 32, the sleeve heat exchange device 32 includes a sleeve 1 and a drainage pipeline 18, the sleeve has a water inlet and a water outlet, and the water inlet is connected to the water tank 22 The water outlet communicates with the circulation pump 23; the drainage pipeline 18 communicates the casing with the water tank 22.

[0072] The sleeve heat exchange device 32 of this embodiment is the sleeve heat exchange device 32 described in Embodiment 1. The difference from Embodiment 1 is that the sleeve h...

Embodiment 3

[0090] Such as Figure 7 with Figure 8 As shown, the present embodiment provides a dishwasher, the dishwasher includes a housing, a door 21 is arranged on one side of the housing, an inner tank of the dishwasher is arranged in the housing, and a spray arm is arranged in the inner tank , The bottom of the liner is provided with a water tank 22, a circulation pump 23 and a heat pump system. One side of the dishwasher is provided with a water softening device 35 . The heat pump system includes:

[0091] evaporator 30 and compressor 33,

[0092] The casing heat exchange device 32 includes a casing, the water inlet end and / or the water outlet end of the casing is provided with a detachable first connection structure 4; or a plurality of casings, different casings can pass through The disassembled first connecting structures 4 are connected in sequence to form a water flow channel;

[0093] The evaporator 30 , the compressor 33 and the casing heat exchange device 32 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com