Self-circulation return material gradient humidification flue gas desulfurization and denitrification system and method

A technology for desulfurization, denitrification, and wet flue gas, applied in separation methods, chemical instruments and methods, gas treatment, etc., to achieve the effects of solving the high rate of material return accidents, eliminating sticky wall scaling, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

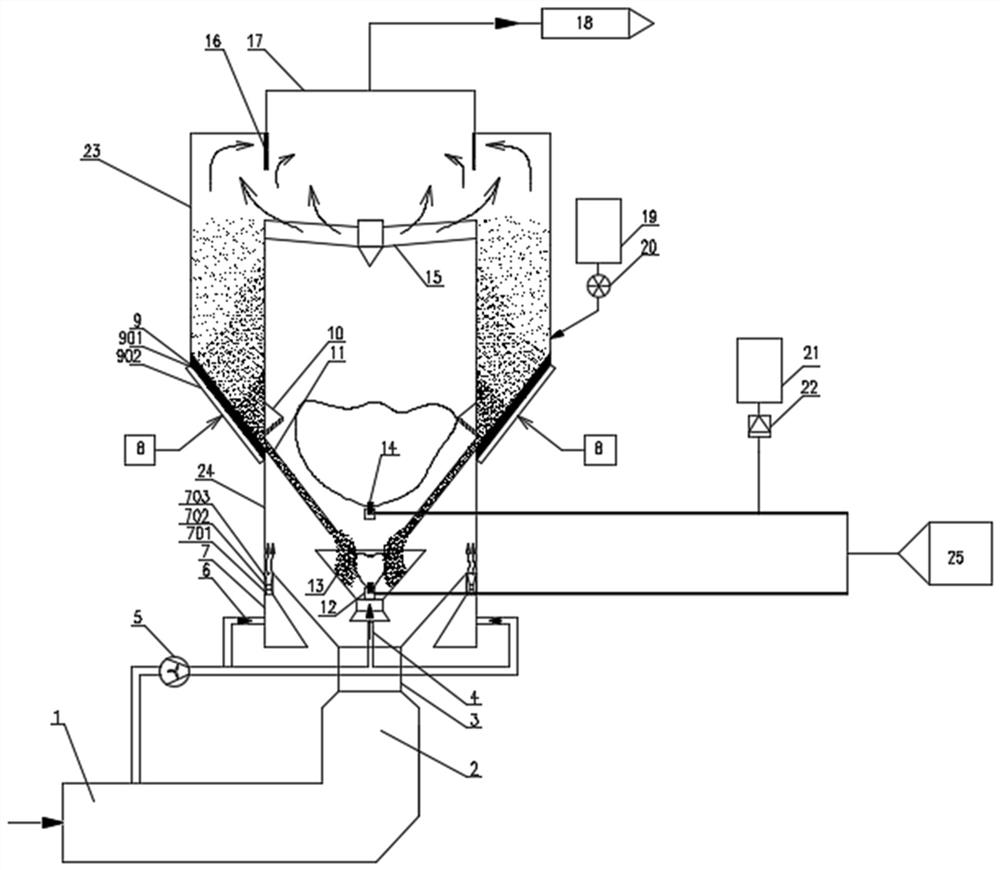

[0030] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

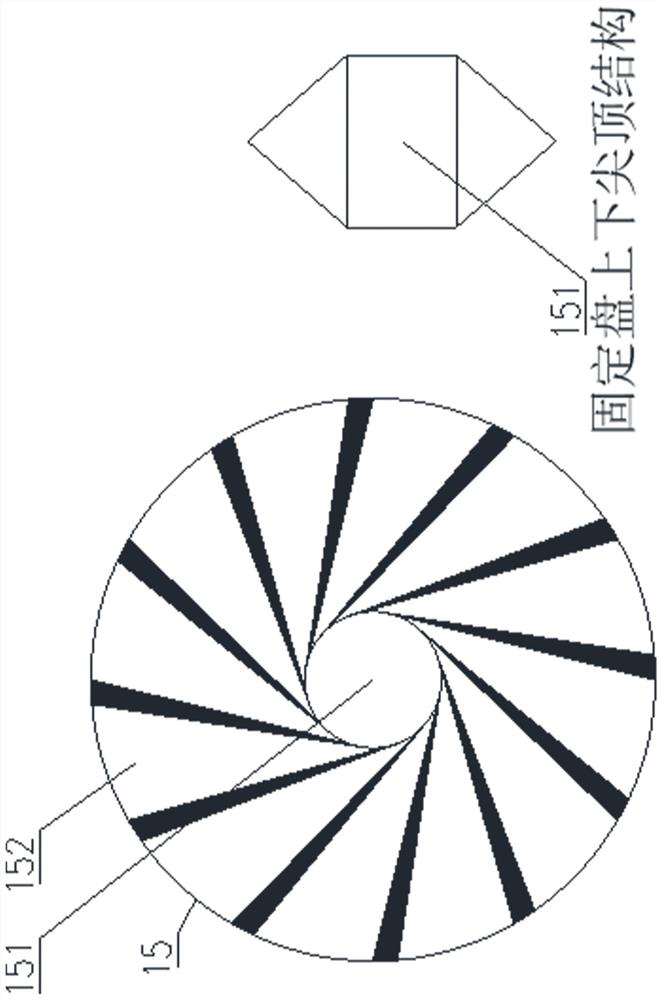

[0031] Please refer to figure 1 , the present invention provides a self-circulation return material gradient humidification flue gas desulfurization and denitrification system, the system includes an inlet flue 1, a reaction tower body 24, and an intake smoke box 2 communicated with the inlet flue 1, the The system also includes a booster fan 5, an air curtain smoke box intake pipe 6, an air curtain smoke box 7, and an air curtain synergistic ring 10; The smoke curtain boxes 7 are connected by pipes; the air curtain synergistic rings 10 are arranged on both sides of the middle of the reaction tower body 24 .

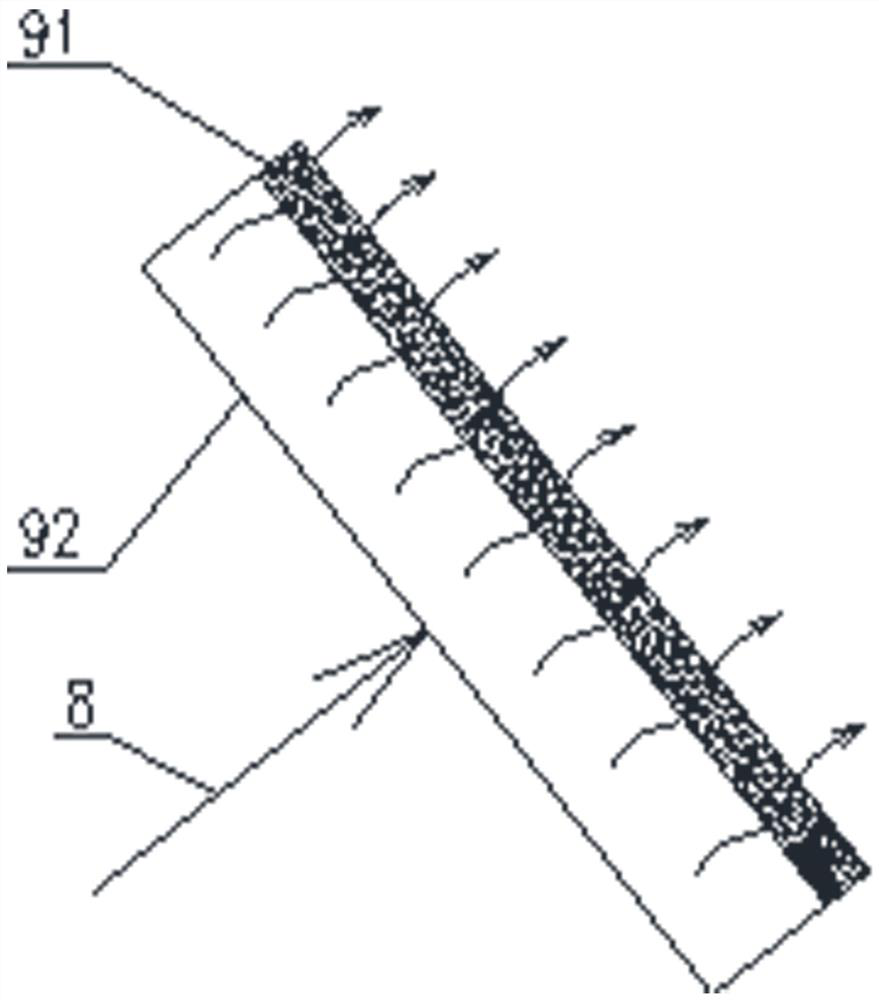

[0032] Preferably, the air curtain smoke box 7 includes an air curtain Venturi inlet section 701, an air curtain Venturi throat section 702 and an air curtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com