Electric hydraulic power-assisted steering system and crane

A technology of hydraulic power steering and electric power assist, which is applied in electric steering mechanism, power steering mechanism, steering mechanism, etc., can solve the problems such as the inability to meet the steering requirements of large axle loads, the deviation of vehicles in high-speed driving, and the large steering resistance torque of tires. , to achieve the effect of improving high-speed steering performance, improving holding ability, and improving deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

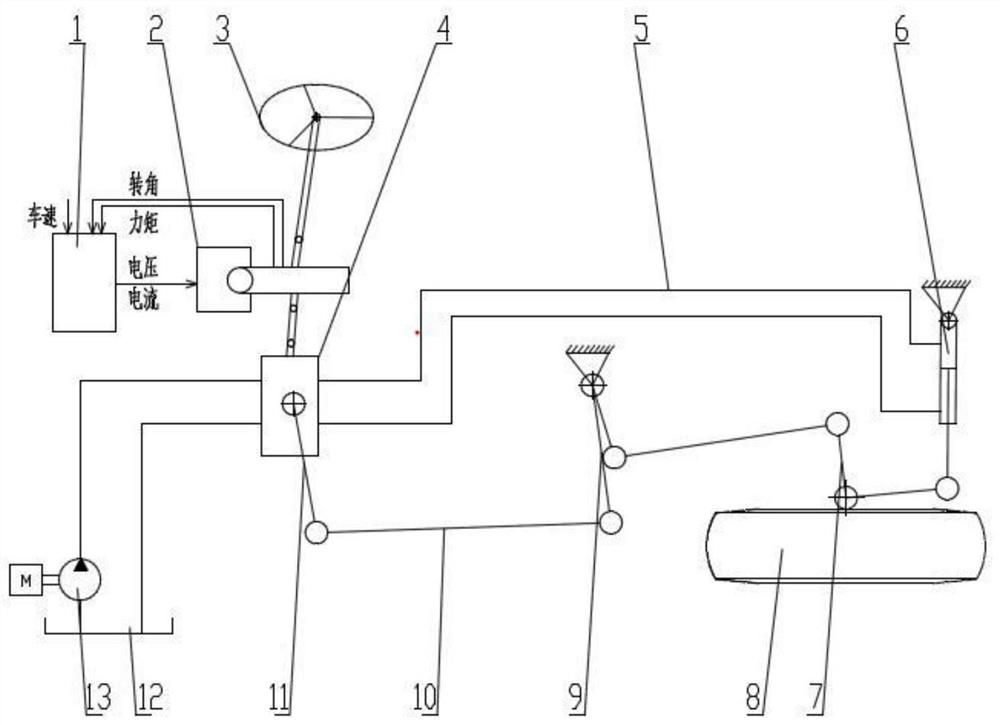

[0033] Such as figure 1 As shown, an electrohydraulic power steering system includes a steering wheel 3, an electric power assist device 2, and a steering gear 4;

[0034] The electric power booster 2 is located between the steering wheel 3 and the steering gear 4, and can directly and reliably change the boosting characteristics of the steering wheel, and comprehensively control the input torque and rotation angle of the steering gear; the electric power booster 2 includes a motor, a sensor, a speed reduction mechanism, etc. , the sensor may include an angle sensor, a torque sensor, etc. and various combinations thereof; the electric power assist device controls the motor rotation angle through the angle sensor to achieve an automatic back-to-center effect.

[0035]The steering wheel 3 is connected to the steering gear 4 through a steering column or a steering transmission shaft, the oil port at the input end of the steering gear 4 is connected to the oil pump 13 and the hydr...

Embodiment 2

[0045] A crane, including the electro-hydraulic power steering system, uses the combined effect of electric power assist and hydraulic power assist on the crane product to control the mechanical steering action of the vehicle. Through the joint action of electric power assist and hydraulic power assist, it can meet the comprehensive requirements of steering comfort and safety of large-axle-load construction machinery vehicles, realize the power steering function of the steering wheel, improve the driving convenience of the vehicle at low speeds, and reduce the phenomenon of steering wheel fluttering at high speeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com